Cereal drier

A grain dryer and drying technology, which is applied in the direction of grain drying, dryer combination, dryer, etc., can solve the problems of increasing manpower and material resources and costs, low automation level, and high energy consumption of equipment, so as to achieve good drying effect and save resources , High drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

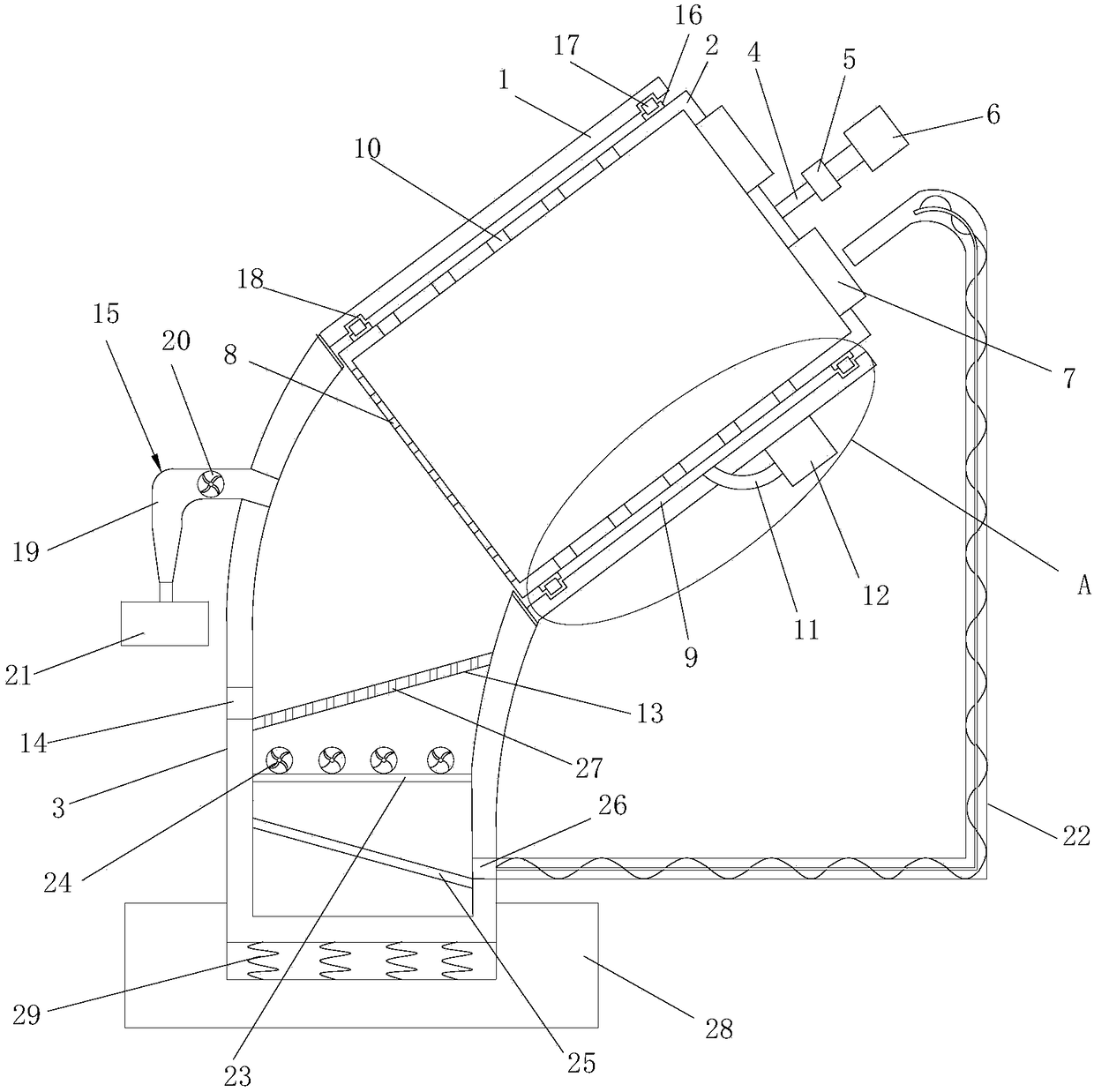

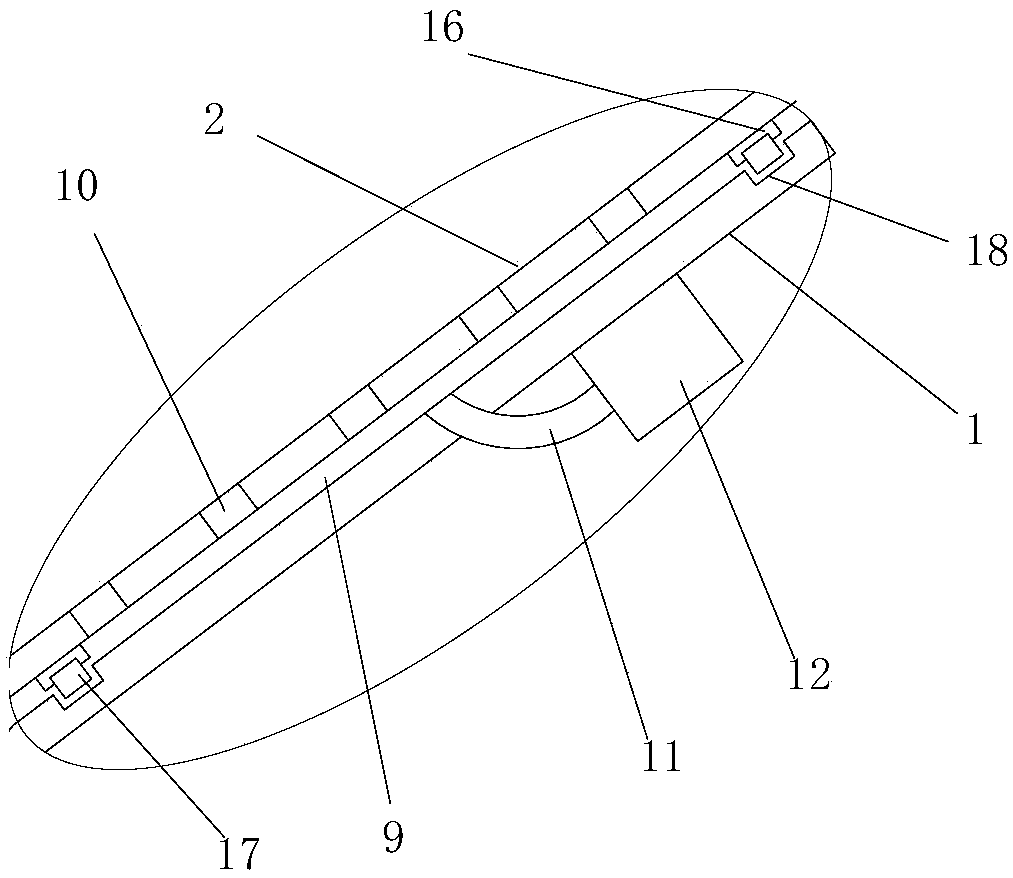

[0028] Such as figure 1 , figure 2 As shown, a grain dryer includes a drying outer cylinder 1, a drying inner cylinder 2 and a receiving cylinder 3, the drying inner cylinder 2 is rotatably connected to the drying outer cylinder 1, and the drying outer cylinder 1 is fixedly connected to the receiving cylinder 3 , the drying outer cylinder 1 is a cylinder structure with upper and lower openings, the top of the drying inner cylinder 2 is provided with a rotating shaft 4, and the rotating shaft 4 is fixedly connected with the output shaft of the motor 6 through a coupling 5, and the top of the drying inner cylinder 2 is also provided with a feeding Outlet 7, discharge holes 8 are evenly distributed on the bottom of the drying inner cylinder 2, a hot air chamber 9 is formed between the drying inner cylinder 2 and the drying outer cylinder 1, and a drying hole 10 communicating with the hot air chamber 9 is opened on the side wall of the drying inner cylinder 2 , the hot air chamb...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the purification adsorption coating is prepared from the following raw materials in mass percentage: polyimide resin 42%, aluminum oxide 15%, antibacterial auxiliary agent 11%, diatomite 8%, Nano titanium dioxide 5%, far-infrared ceramic powder 4%, MCM-41 silicon molecular sieve 4%, carboxymethyl cellulose 2%, epoxy soybean oil 3%, magnesium stearate 2.5%, SL-646 oily high light and soft light Oil 2%, Citric Acid 0.5%, Linalool 0.6%, Levomenthone 0.4%. Among them, the antibacterial auxiliary agent includes the following components by weight: 32 parts of lavender essential oil, 7 parts of nano-silver oxide, 5 parts of sodium carboxymethyl cellulose, 3 parts of titanate coupling agent, 2 parts of polyethylene wax, dimethyl 2 parts of silicone oil, 270 parts of β-cyclodextrin, 30 parts of sodium carbonate, 130 parts of distilled water.

[0036] The preparation method of the antibacterial auxiliary agent is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com