A preparation method of polyazobenzene multifunctional nanoparticles based on rare earth up-conversion materials

A rare earth up-conversion and nanoparticle technology, applied in the directions of luminescent materials, chemical instruments and methods, preparations for in vivo tests, etc., can solve the problems of difficult tracking, tumor diagnosis and treatment separation, and achieve the effect of high drug loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

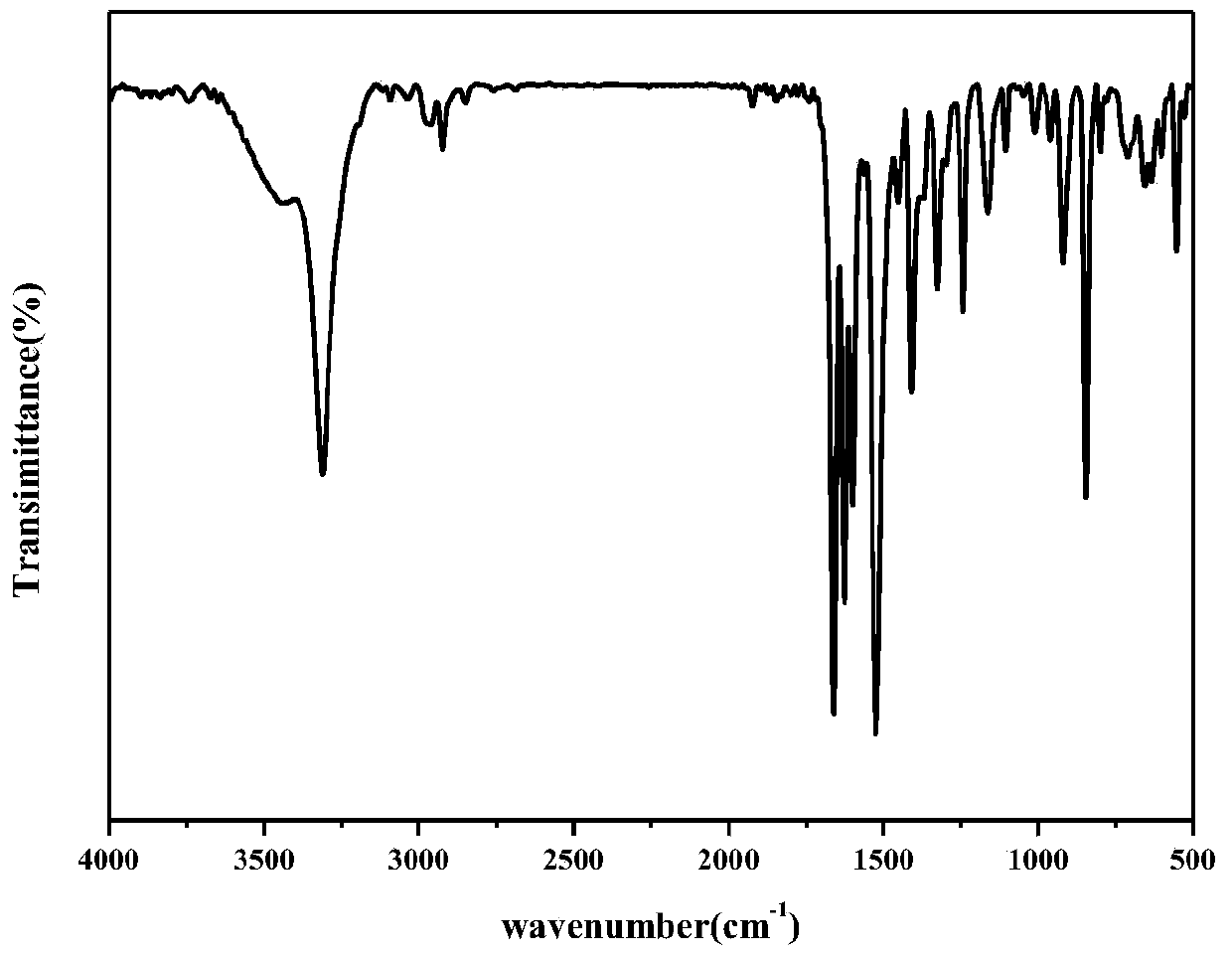

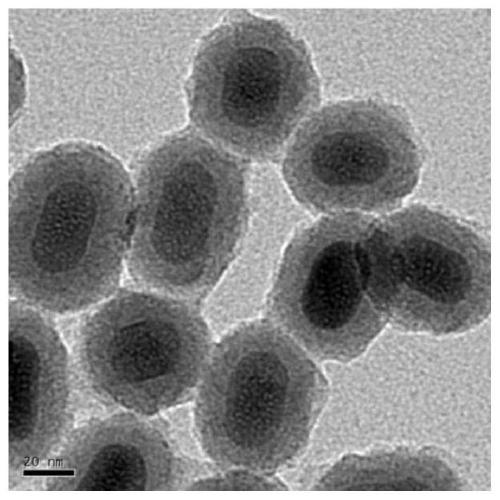

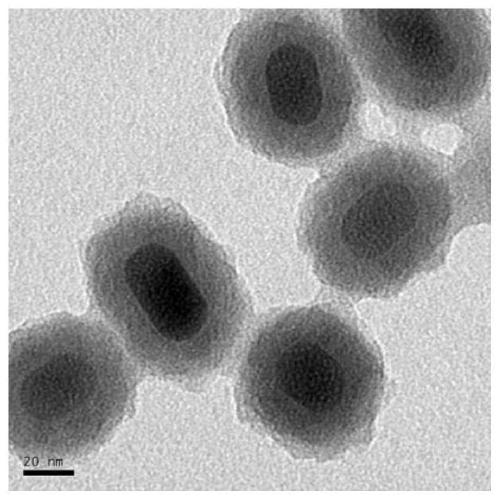

[0029] (1) Preparation of NaYF 4 :0.5%Yb 3+ ,30%Tm 3+ / NaYF 4 Core / shell up-conversion nanoparticles: a): In a 100ml four-necked flask, add 1-octadecene 15ml and oleic acid 7ml, then add 3.975ml yttrium chloride aqueous solution (0.2mol / L) and 1ml ytterbium chloride aqueous solution ( 0.2mol / L) and 25μL thulium chloride aqueous solution (0.1mol / L), the mixed solution was slowly heated up to 120°C under a nitrogen atmosphere to remove moisture and oxygen in the reaction system, and then continued to heat up to 150°C and kept for 50min. After removing the heating mantle and cooling to room temperature naturally, 5ml of methanolic sodium hydroxide solution (0.5mol / L) and 8ml of methanolic ammonium fluoride solution (0.5mol / L) were mixed evenly and quickly added to the four-necked flask, followed by the reaction The solution was stirred at room temperature for 1 hour; the temperature was slowly raised to 100°C to remove methanol and water, then the temperature was rapidly raise...

Embodiment 2

[0034] (1) Preparation of NaYF 4 :0.5%Yb 3+ ,30%Tm 3+ / NaYF 4 Core / shell up-conversion nanoparticles: a): Add 10ml of 1-octadecene and 5ml of oleic acid into a 100ml four-neck flask, then add 1ml of yttrium chloride aqueous solution (0.2mol / L) and 0.5ml of ytterbium chloride aqueous solution (0.2mol / L) and 10μL thulium chloride aqueous solution (0.1mol / L), the mixed solution was slowly heated to 150°C under a nitrogen atmosphere to remove moisture and oxygen in the reaction system, and then continued to heat up to 200°C for 60min. Finally, the heating mantle was removed, and after natural cooling to room temperature, 3ml of methanolic sodium hydroxide solution (0.5mol / L) and 5ml of methanolic ammonium fluoride solution (0.5mol / L) were mixed evenly and then quickly added to the four-necked flask, followed by The reaction solution was stirred at room temperature for 1 h; the temperature was slowly raised to 150°C to remove methanol and water, then the temperature was rapidly ...

Embodiment 3

[0039] (1) Preparation of NaYF 4 :0.5%Yb 3+ ,30%Tm 3+ / NaYF 4 Core / shell up-conversion nanoparticles: a): Add 1-octadecene 20ml and oleic acid 10ml in a 100ml four-necked flask, then add 5ml yttrium chloride aqueous solution (0.2mol / L), 4ml ytterbium chloride aqueous solution ( 0.2mol / L) and 30μL thulium chloride aqueous solution (0.1mol / L), the mixed solution was slowly heated up to 130°C under a nitrogen atmosphere to remove moisture and oxygen in the reaction system, and then continued to heat up to 170°C and kept for 55min. After removing the heating mantle and cooling to room temperature naturally, 6ml of methanolic sodium hydroxide solution (0.5mol / L) and 10ml of methanolic ammonium fluoride solution (0.5mol / L) were mixed evenly and quickly added to the four-necked flask, followed by the reaction The solution was stirred at room temperature for 1 hour; the temperature was slowly raised to 130°C to remove methanol and water, and then the temperature was rapidly raised ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com