N-doped graphene-cerium oxide composite catalyst and application of N-doped graphene-cerium oxide composite catalyst to treatment of degradation-resistant acid wastewater

A composite catalyst and cerium oxide technology, which is applied in the direction of oxidized water/sewage treatment, physical/chemical process catalyst, water/sewage treatment, etc., can solve the problem of low treatment efficiency, achieve high degradation and mineralization efficiency, and low synthesis cost , to avoid the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 N-doped graphene-cerium oxide composite catalyst (NG-CeO 2 ) preparation

[0048] (1) Weigh 0.4g of cerous nitrate hexahydrate and 0.2g of glucose and dissolve in 20ml of water, add 2.0g of melamine and transfer to a ceramic crucible, and stir thoroughly. Put it in a forced air drying oven and dry it at 80°C for 12 hours to obtain a light yellow solid.

[0049] (2) Fully grind the light yellow solid in step (1), transfer the solid to a tube furnace, and burn it at 450°C for 1 hour under the protection of nitrogen, then raise the temperature to 800°C at a heating rate of 5°C / min After roasting for 1.5h, after cooling to room temperature, a black powder was obtained. The nitrogen flow rate is 0.01L / min.

[0050] The black powder obtained in step (2) is ground to obtain the N-doped graphene-cerium oxide composite catalyst (NG-CeO 2 ).

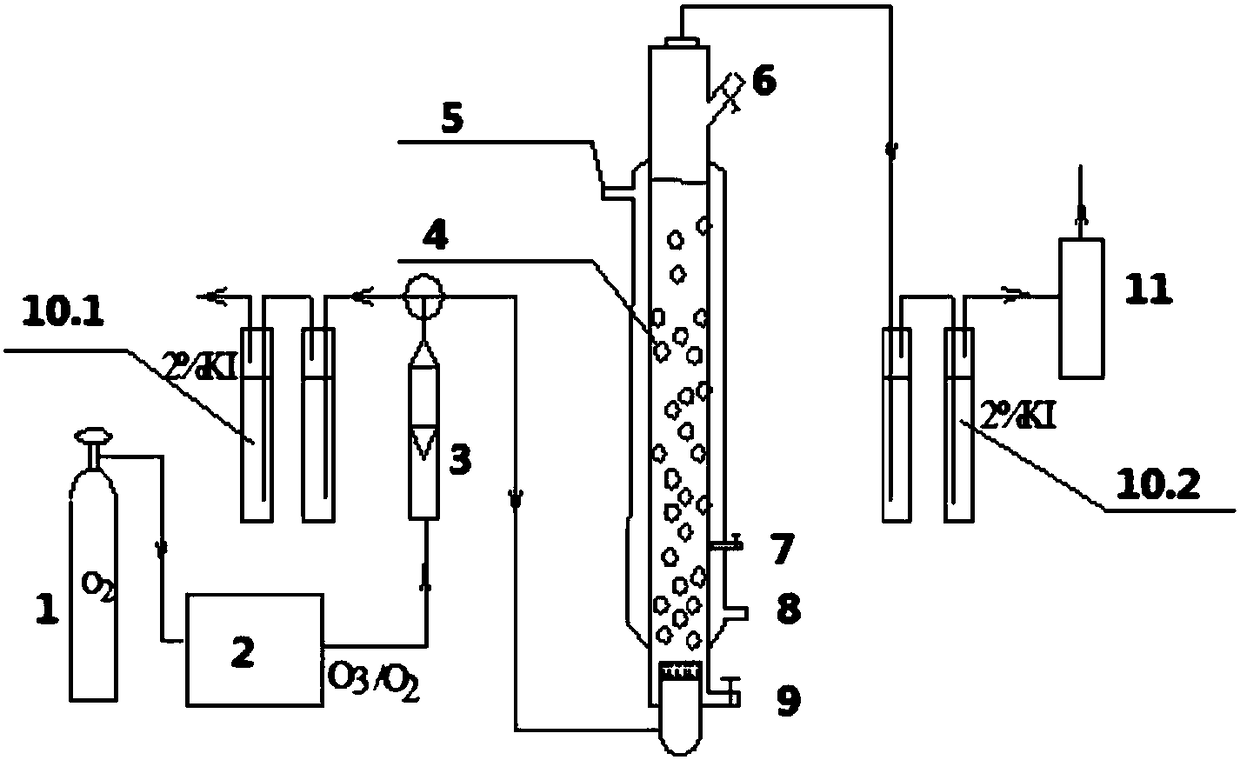

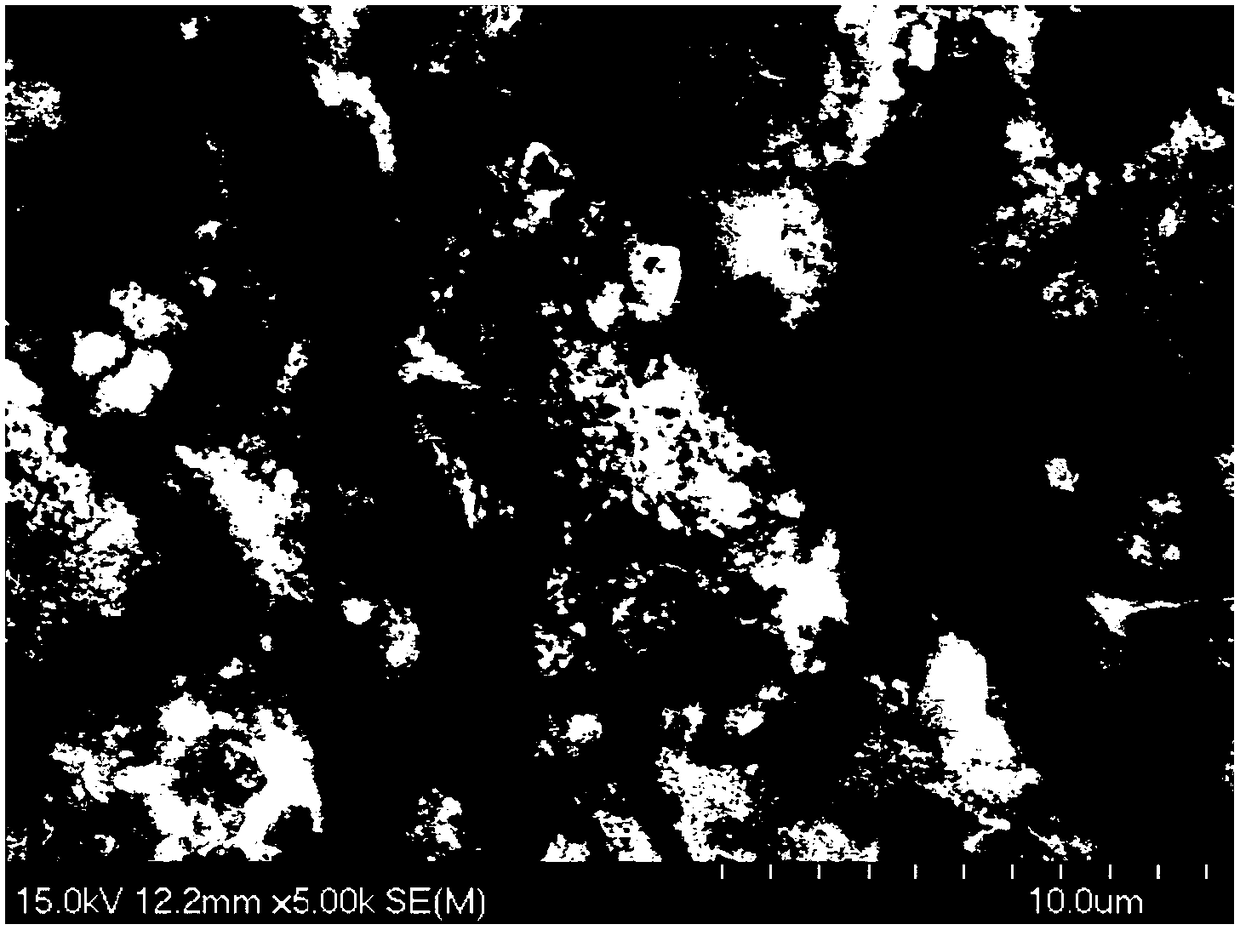

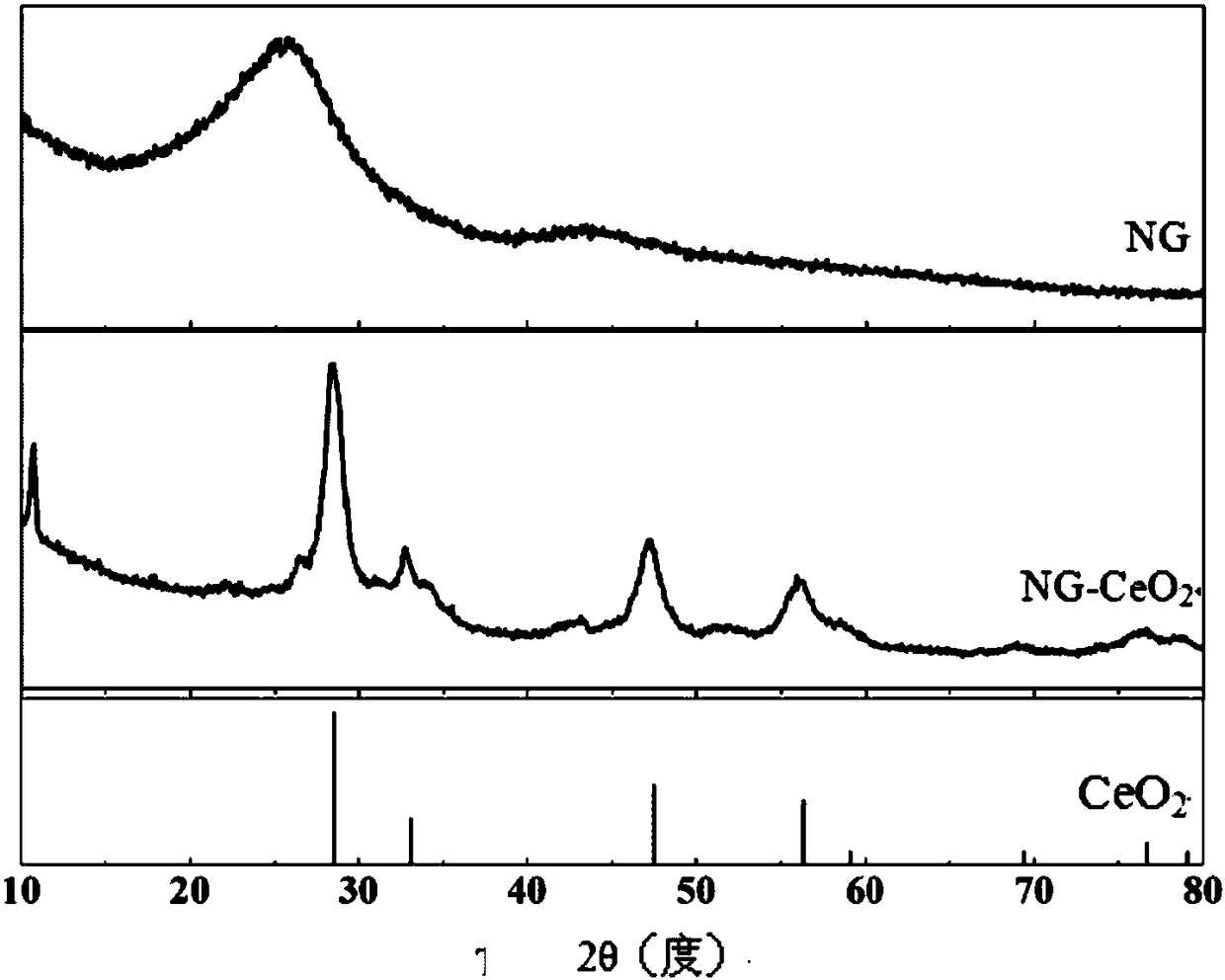

[0051] NG-CeO 2 The SEM characterization diagram, XRD characterization diagram and Raman characterization diagram are r...

Embodiment 2

[0056] Adopt the NG-CeO that embodiment 1 prepares 2 Catalytic H 2 o 2 / O 3 The system degrades acetic acid simulated wastewater. The acetic acid concentration in the acetic acid simulated wastewater is 100 mg / L, and the volume of the acetic acid simulated wastewater is 250 ml. Based on the volume of acetic acid simulated wastewater, the dosage of catalyst is 0.04g / L, the concentration of hydrogen peroxide is 100mg / L, and then the pH value of acetic acid simulated wastewater is adjusted to 1.0 with sulfuric acid.

[0057] The experiment adopts the semi-batch method, O 2 / O 3 The mixed gas flow rate is 0.1L / min, and the ozone concentration in the mixed gas is 99mg / L.

Embodiment 3~6

[0069] Adopt the NG-CeO that embodiment 1 prepares 2 Catalytic H 2 o 2 / O 3The system degrades acetic acid simulated wastewater. The acetic acid concentration in the acetic acid simulated wastewater is 100 mg / L, and the volume of the acetic acid simulated wastewater is 250 ml. Based on the volume of acetic acid simulated wastewater, the dosage of catalyst is 0.04g / L, the dosage of hydrogen peroxide is 100mg / L, and then the pH value of acetic acid simulated wastewater is adjusted to 5, 0.5, 0.25 with sulfuric acid and 0.

[0070] The experiment adopts the semi-batch method, O 2 / O 3 The mixed gas flow rate is 0.1L / min, and the ozone concentration in the mixed gas is 99mg / L.

[0071] After 60 minutes of reaction, samples were taken for detection, and the degradation of acetic acid simulated wastewater is shown in Table 1.

[0072] Table 1

[0073] Example

[0074] It can be seen from the data in Table 1 that NG-CeO 2 / H 2 o 2 / O 3 The catalytic system can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com