Diatomite loaded nitrogen doped titanium dioxide/silicon dioxide photocatalytic coating

A technology of diatomite and photocatalysis, applied in physical/chemical process catalysts, chemical/physical processes, coatings, etc., can solve the problems of poor dispersion and low efficiency of decomposing harmful gases in the room, and achieve improved dispersion and degradation process Irreversible, protective effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

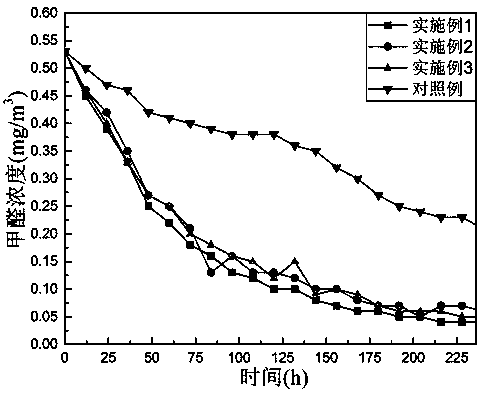

Embodiment 1

[0030] A diatomaceous earth loaded N-TiO 2 / SiO 2 Photocatalytic coating, in parts by weight, its raw material composition is: 25 parts of water, diatomaceous earth load N-TiO 2 / SiO 2 18 parts, Ca(OH) 2 2.5 parts, wollastonite powder 7.5 parts, redispersible rubber powder 2.5 parts, bentonite 2.5 parts, dispersant 1.5 parts, curing agent 1 part, defoamer 0.8 parts.

[0031] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0032] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.25g of urea, 15ml of 5mol / L nitric acid solution, 2.5 Dissolve ml tetraethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 150°C for 10 hours After coolin...

Embodiment 2

[0037] A diatomaceous earth loaded N-TiO 2 / SiO 2 The photocatalytic coating, in parts by weight, consists of raw materials: 30 parts of water, diatomaceous earth loaded N-TiO 2 / SiO 2 16 parts, Ca(OH) 2 2.5 parts, 2.5 parts of redispersible rubber powder, 7.5 parts of wollastonite powder, 2.5 parts of bentonite, 1 part of dispersant, 1 part of curing agent, and 0.8 part of defoamer.

[0038] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0039] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.25g of urea, 15ml of 5mol / L nitric acid solution, 2.5 Dissolve ml tetraethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 130°C for 10 h...

Embodiment 3

[0044] A diatomaceous earth loaded N-TiO 2 / SiO 2 Photocatalytic coating, in parts by weight, its raw material composition is: 25 parts of water, diatomaceous earth load N-TiO 2 / SiO 2 20 parts, wollastonite powder 7.5 parts, Ca(OH) 2 2.5 parts, 2 parts of redispersible rubber powder, 2.5 parts of bentonite, 1.5 parts of dispersant, 1 part of curing agent, 0.8 part of defoamer.

[0045] The diatomaceous earth supported N-TiO 2 / SiO 2 Preparation of:

[0046] (1) Dissolve 3ml of titanium isopropoxide in 21ml of ethylene glycol and stir magnetically for 4 hours to obtain solution A; mix 0.5g of cetyltrimethylammonium bromide, 0.8ml of ammonia water, 15ml of 5mol / L nitric acid solution, 3ml Dissolve ethyl orthosilicate in ethanol, and stir magnetically for 30 minutes to obtain solution B; drop solution A into solution B and mix evenly, then transfer it to a stainless steel hydrothermal synthesis reactor with a polytetrafluoroethylene liner and react at 170°C for 10 hours;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com