Preparation method of zirconium-oxide/carbon composite fiber modified epoxy coating

A technology of fiber modification and epoxy coating, which is applied in the field of material chemistry, can solve problems such as difficulty in fully exerting performance and difficult control of composite material structure, and achieve enhanced mechanical properties and corrosion resistance, fewer material structural defects, and uniform size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a zirconia / carbon composite fiber modified epoxy coating comprises the following steps.

[0028] (1) Preparation of zirconia / carbon fiber.

[0029] First, add 15g of zirconium acetate (15%) solution into a vial containing a mixed solution of 2mL N,N-dimethylformamide (DMF) and 2mL of absolute ethanol, stir for 2 hours, and then add 0.7g of polyvinylpyrrolidone (PVP) powder, continue to stir at 25°C for 12 hours to obtain a transparent and uniform PVP / zirconium acetate composite precursor solution; put the precursor solution into a 10mL glass syringe , and install a flat needle with an inner diameter of 0.32mm, add a positive voltage of 20Kv, a negative voltage of -1.5Kv, set the distance between the needle and the spinning receiver at 17cm, and then spin at a speed of 1mL / h to obtain PVP / Zirconium acetate composite nanowires. The product was first dried in a vacuum oven at 60°C to ensure that the solvent was fully volatilized; then, the obtaine...

Embodiment 2

[0037] (1) Preparation of pure carbon fibers.

[0038]First, add 0.7 g of polyvinylpyrrolidone (PVP) powder into a vial containing a mixed solution of 6 mL of N,N-dimethylformamide (DMF) and 6 mL of absolute ethanol, and stir at 25 °C for 12 hours Finally, a transparent and uniform PVP solution is obtained. Put the solution into a 10mL glass syringe and install a flat needle with an inner diameter of 0.32mm. Apply a positive voltage of 20Kv and a negative voltage of -1.5Kv. The needle and the spinning receiver The distance was set to 17cm, and then spinning was carried out at a propulsion speed of 1mL / h to obtain PVP nanowires. The product was first dried in a vacuum oven at 60°C to ensure that the solvent was fully evaporated; then, the obtained PVP nanowires were heated at 400 Calcined for 2 hours, then heated up to 600°C at a rate of 1°C / min, held for 3 hours, and then cooled naturally to obtain pure carbon fibers. The whole process of calcination was carried out under the ...

experiment example

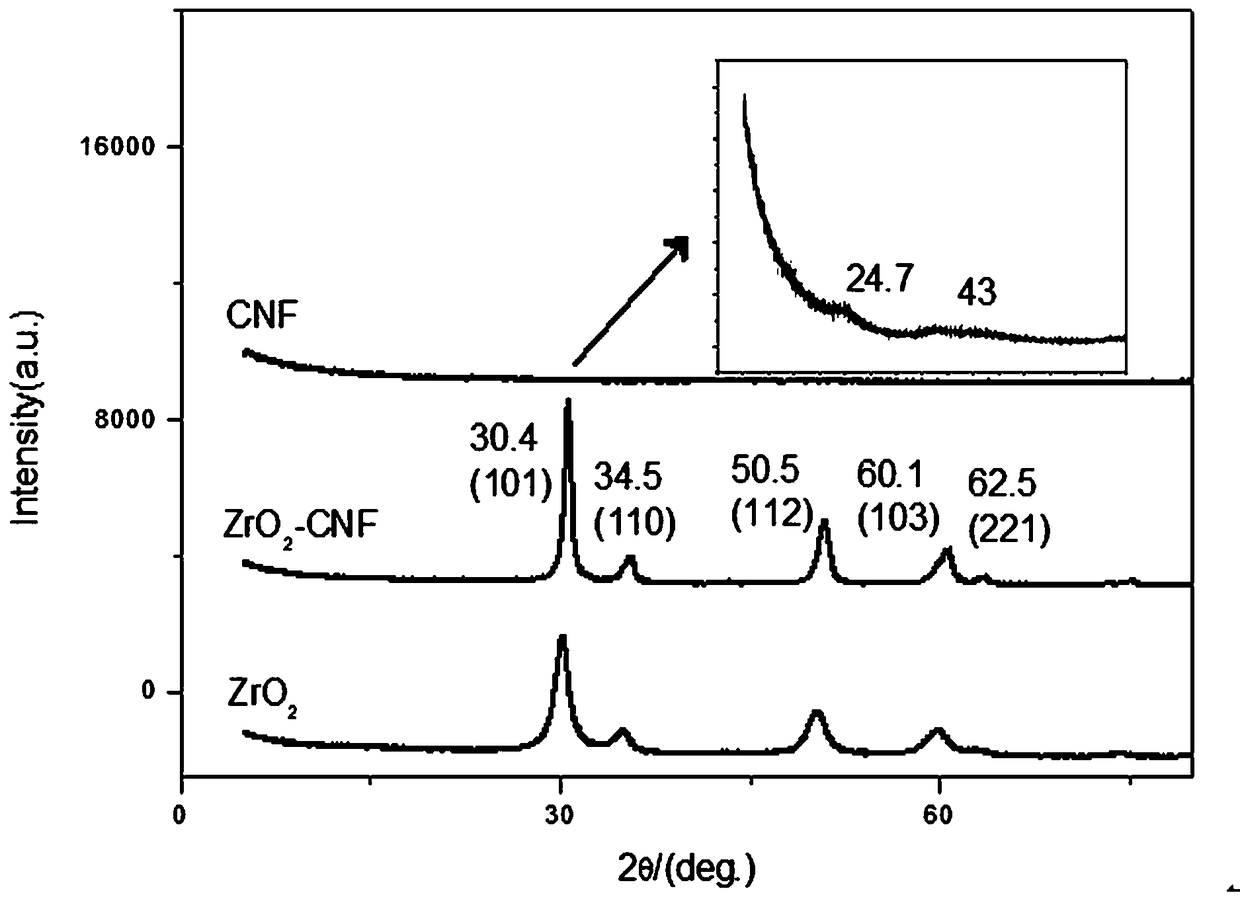

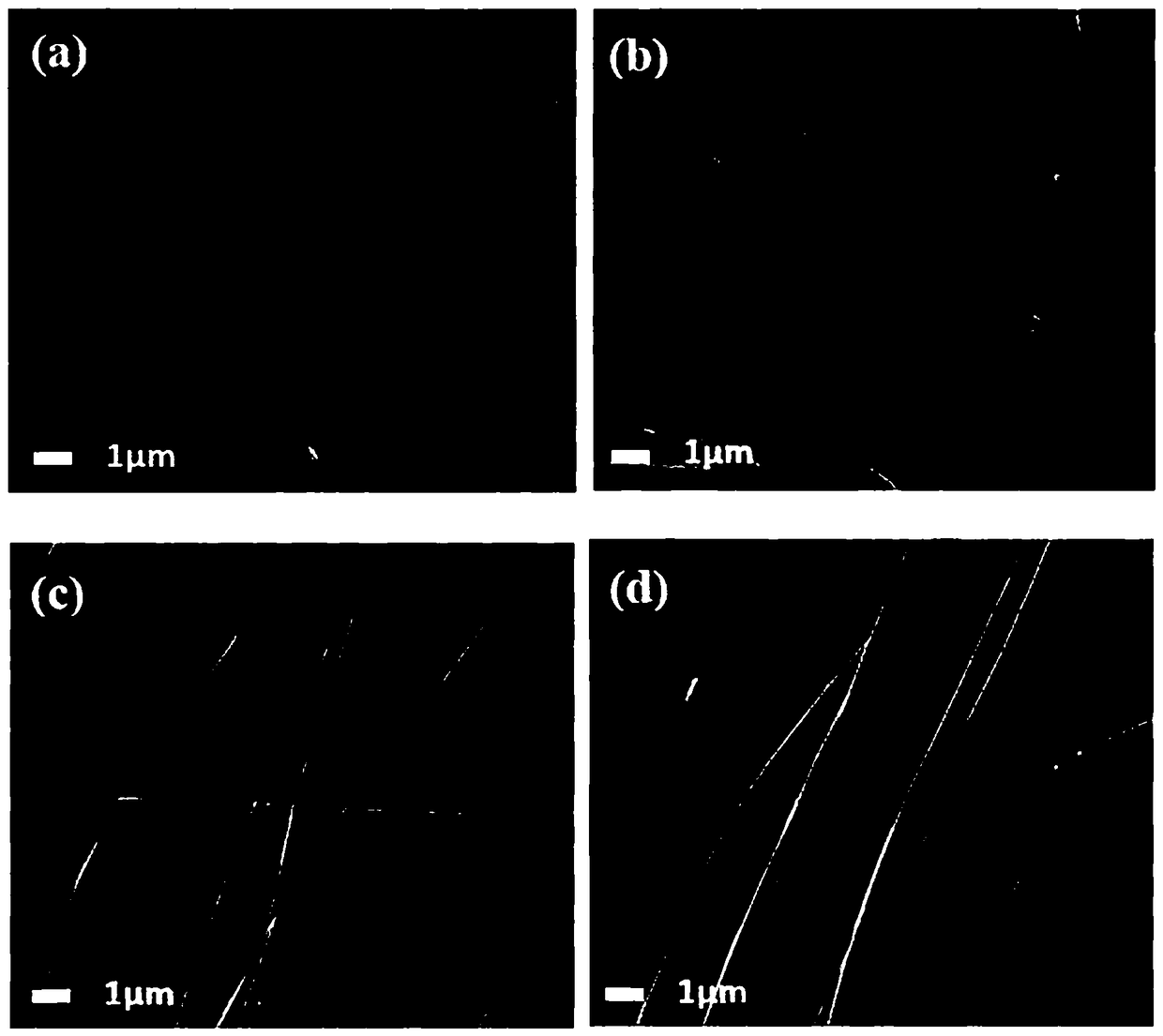

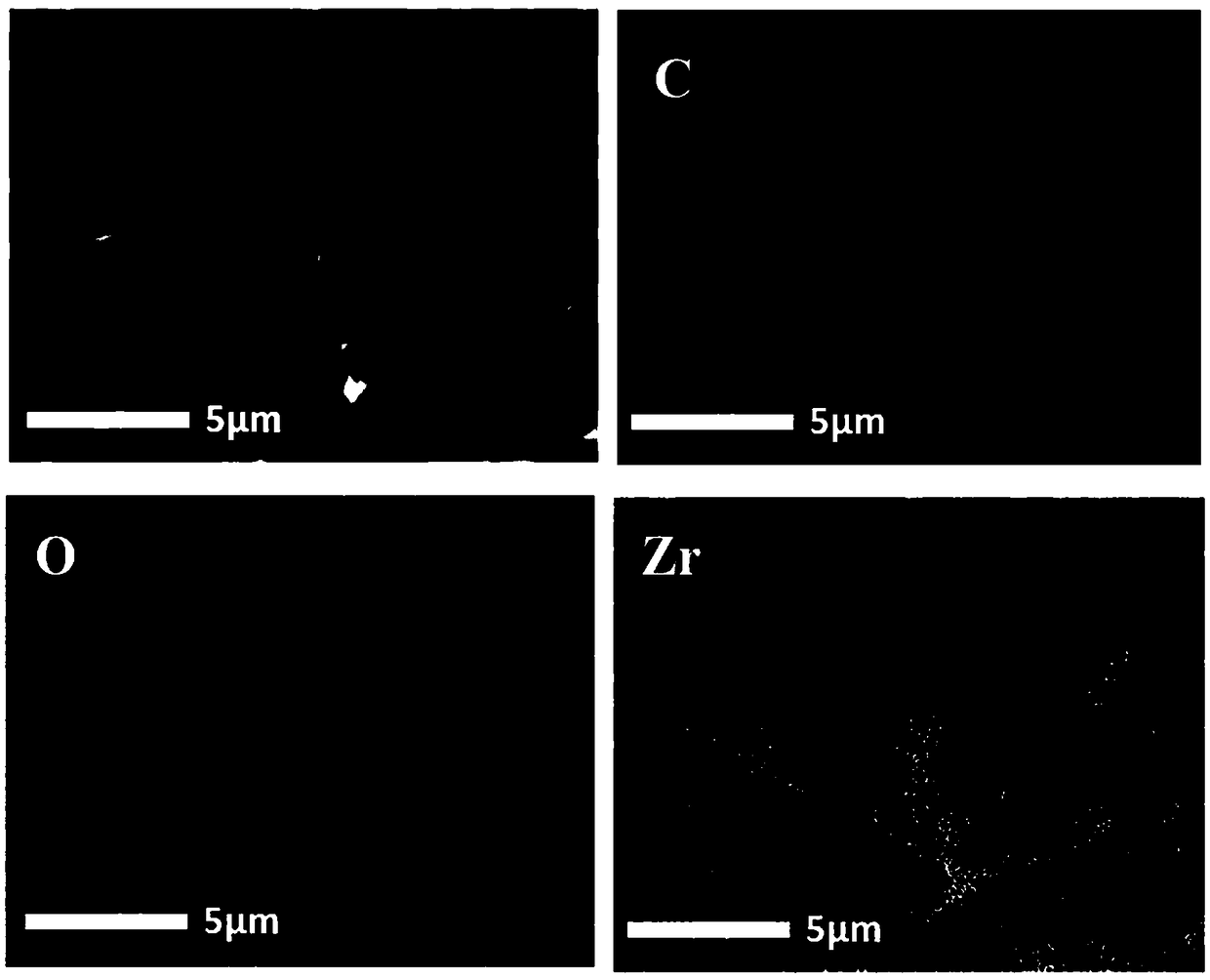

[0046] The present invention uses zirconium acetate and polyvinyl pyrrolidone as base materials to prepare zirconia-carbon composite fibers (ZrO 2 -CNF), the obtained fiber has the characteristics of uniform fiber size, less material structural defects and uniform distribution of zirconia. After organic modification, it has good compatibility and dispersion when added to epoxy coating properties, which can effectively improve the mechanical properties and corrosion resistance of epoxy coatings. The results of XRD analysis, scanning electron microscope analysis and component analysis of the samples in Example 1 show that the experiment successfully prepared zirconia-carbon composite fibers, and the oxidation Zirconium is uniformly dispersed on the carbon fiber; at the same time, tensile tests, microhardness tests, and EIS experiments were carried out on these samples to study the mechanical properties and corrosion resistance of nano-zirconia-carbon fiber composite coatings. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com