Nicotine-zinc oxide complex, method for preparing same and tobacco product with nicotine-zinc oxide complex

A technology of tobacco products and compounds, which is applied in the fields of tobacco, processed tobacco, smoker’s products, etc. It can solve the problems of gastrointestinal or respiratory tract irritation, excessive nicotine release, physical discomfort, etc., and achieve good product stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] 1. Preparation of nicotine-zinc oxide complex

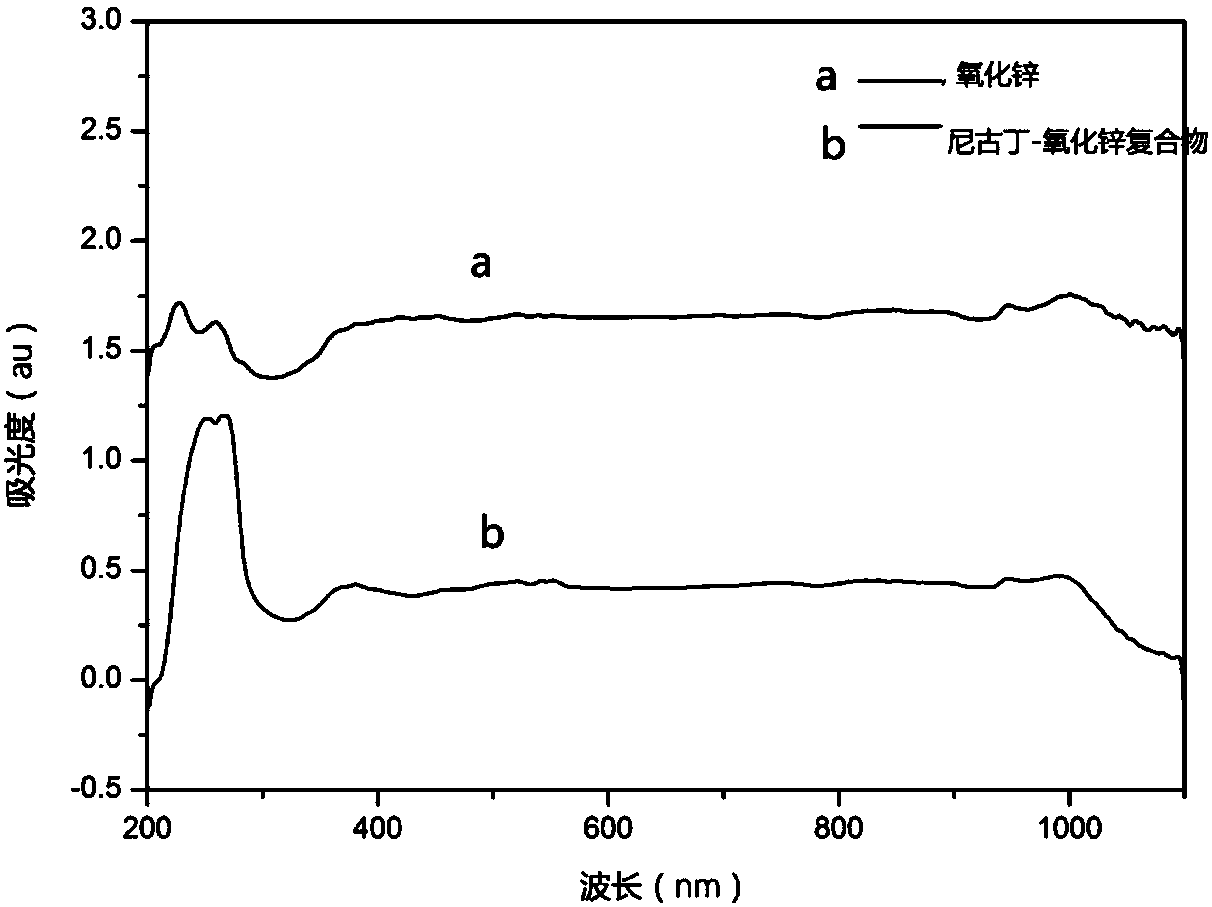

[0035] Accurately weigh 1.5 g of zinc sulfate solid, add distilled water, and ultrasonically dissolve the solid completely. Then add 7.5mL of distilled water, sonicate until completely dissolved, then add 0.2mL of nicotine dropwise to convert zinc (II) into zinc oxide. After the reaction, it was freeze-dried to obtain a white powder product. Determined by ultraviolet absorption spectrometry, it contains about 15% nicotine, which means that nicotine can interact with Zn 2+ The role thus exists in the Zn 2+ Formed zinc oxide precipitates.

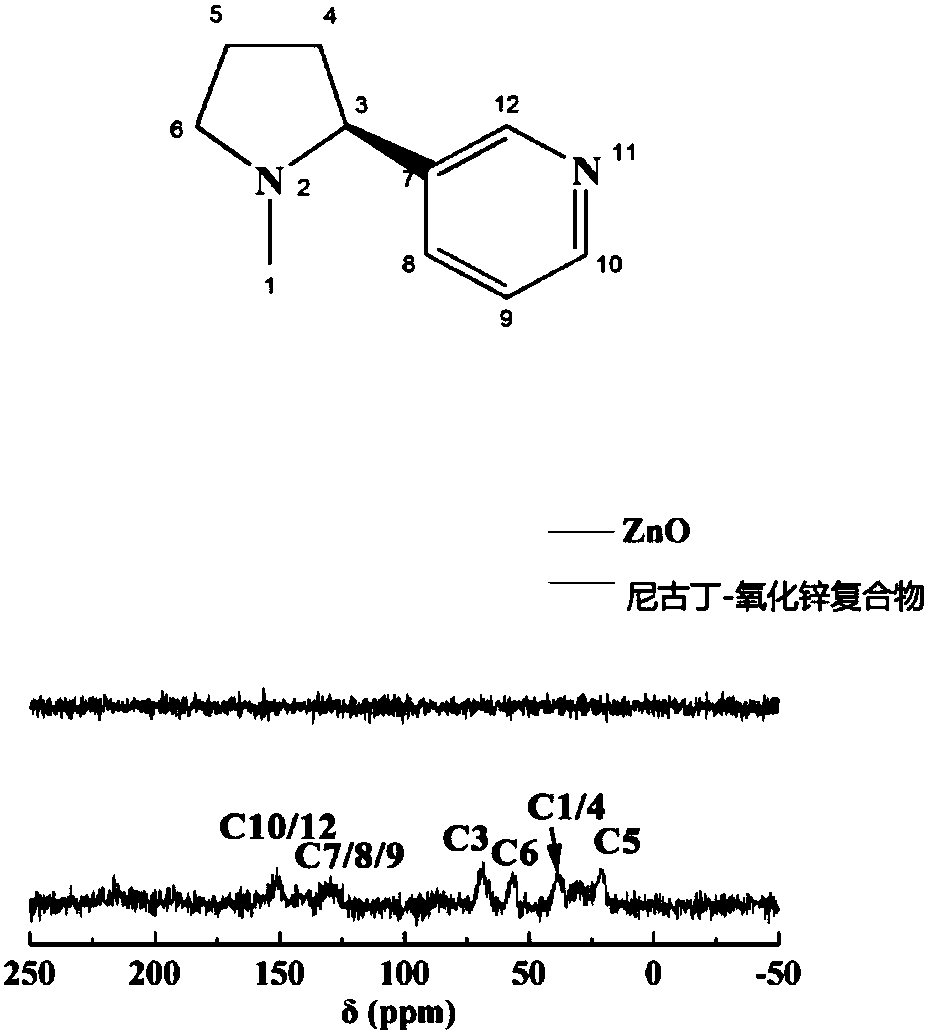

[0036] 2. Structural characterization of nicotine-zinc oxide complex

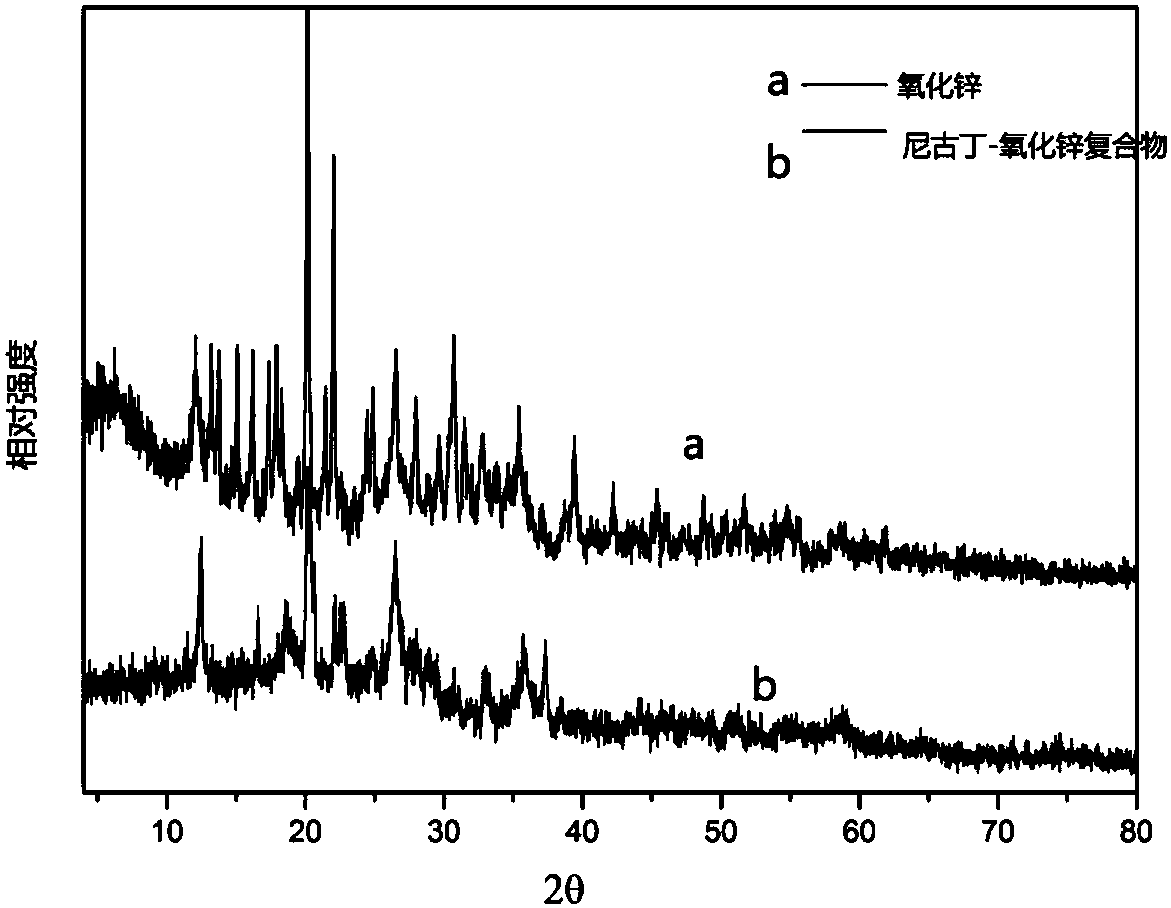

[0037] 2.1 Powder X-ray Diffraction (XRPD)

[0038] The measurement conditions are: one-dimensional detection system X'Pert-PRO super energy detector, CuK α Radiation, IK α2 :IK α1 =0.5,λ 1 = 1.540598, λ 2 =1.544426, the light tube voltage is 40kV, the tube current is 40mA, the 2θ scanning range is 4-80°, the...

Embodiment 2

[0050] 1. Preparation of gum-based chewing tobacco containing nicotine-zinc oxide complex

[0051] a. Take microcrystalline paraffin 30%, acesulfame potassium 56%, propylene glycol 1%, glycerin 1%, lemon flavor 1%, Yunnan olive extract flavor 4%, red yeast rice 3%, nicotine-zinc oxide complex 4 %;

[0052] b. Baking the gum base first, mixing the materials evenly, stirring at 60°C for 60 minutes, forming, extruding, roller rolling, cutting, aging, and subpackaging is the finished product.

[0053] 2. Nicotine dissolution test in vitro

[0054] The product prepared in step 1, the gum-based chewing tobacco containing pure nicotine, and the gum-based chewing tobacco containing shredded tobacco were respectively subjected to nicotine dissolution test in vitro.

[0055] The present invention utilizes an oral cavity simulated chewing instrument to perform in vitro dissolution tests of nicotine on the above three gum-based chewing tobacco products.

[0056] Test method: Add the ar...

Embodiment 3

[0064] 1. Preparation of pouched snus containing nicotine-zinc oxide compound

[0065] a. Take 48% of microcrystalline cellulose, 5% of lemon flavor, 5% of propylene glycol, and 15% of nicotine-zinc oxide complex;

[0066] b. After mixing and sieving the materials, take 20-mesh powder and mix evenly. After baking and heat treatment in a pasteurizer, add water 13%, sodium chloride 3%, sodium carbonate 1%, vitamin A1 %, evenly blended, refrigerated for 12 hours, sprayed with 4% honey, 4% glucose, 1% aspartame, sealed and refrigerated for 24 hours, sterilized by ultraviolet light for 3 hours, and then packaged to obtain the finished product.

[0067] 2. Nicotine dissolution test in vitro

[0068] The product prepared in step 1, the bagged snus containing pure nicotine, and the bagged snus containing shredded tobacco were respectively subjected to nicotine dissolution test in vitro.

[0069] The present invention utilizes an oral cavity simulated chewing instrument to perform in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com