High polymer packaging material being easy to degrade under natural condition and preparation method of high polymer packaging material

A technology of natural conditions and packaging materials, applied in the field of polymer packaging materials and their preparation, can solve the problems of high production cost, high price, and complex production process, and achieve the effects of improving mechanical properties, improving utilization efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

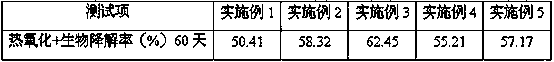

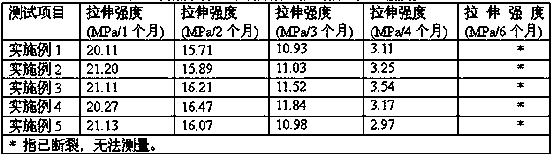

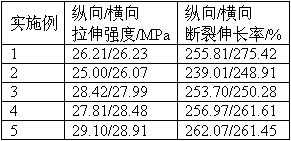

Examples

Embodiment 1

[0026] Example 1 Preparation of easily degradable polymer packaging materials under natural conditions

[0027]A polymer packaging material that is easily degradable under natural conditions, including raw materials in the following mass ratios: high-density polyethylene (brand 5000S, Daqing Petrochemical): phosphorylated distarch phosphate (Jinan Shenghe Chemical Co., Ltd.): nano-copper oxide Mimic Enzyme: Oleoyl Glutamic Acid: Maleic Anhydride Grafted Polyethylene: Manganese Stearate: Hydrotalcite: Methyl Vinyl Ether Maleic Anhydride Copolymer: Sodium Saccharin: Mixed Polyol: Mixed Polyacid: Compatibilizer : The mass ratio of plasticizer: antioxidant is: 12: 0.1: 0.001: 0.001: 0.1: 1: 1: 0.1: 0.001: 2: 2: 1: 1: 0.001;

[0028] The mixed polyol is a mixture of equimolar amounts of 1,5-pentanediol, 4-methyl-2,3-pentanediol, sorbitol, isosorbide and maltitol;

[0029] Described mixed polybasic acid is the mixture of succinic acid, maleic acid, oxalic acid, adipic acid, citric ...

Embodiment 2

[0038] Example 2 Preparation of easily degradable polymer packaging materials under natural conditions

[0039] A polymer packaging material that is easily degradable under natural conditions, including raw materials in the following mass ratios: low density polyethylene (brand 2426H, blue): phosphorylated distarch phosphate (Jiangsu Caiwei Biotechnology Co., Ltd.): nano-oxidation Copper Mimic Enzyme: Lauroyl Glutamic Acid: Maleic Anhydride Grafted Polyethylene: Iron Stearate: Hydrotalcite: Methyl Vinyl Ether Maleic Anhydride Copolymer: Sodium Saccharin: Mixed Polyol: Mixed Polyacid: Compatible The mass ratio of agent: plasticizer: antioxidant is: 35: 0.3: 0.008: 0.005: 0.5: 2: 1: 0.5: 0.005: 8: 8: 3: 10: 0.003;

[0040] The mixed polyol is a mixture of equimolar amounts of 1,5-pentanediol, 4-methyl-2,3-pentanediol, sorbitol, isosorbide and maltitol;

[0041] Described mixed polybasic acid is the mixture of succinic acid, maleic acid, oxalic acid, adipic acid, citric acid and...

Embodiment 3

[0050] Example 3 Preparation of easily degradable polymer packaging materials under natural conditions

[0051] A polymer packaging material that is easily degradable under natural conditions, including raw materials in the following mass ratios: linear low-density polyethylene (brand 7042, Daqing Petrochemical): phosphorylated distarch phosphate (Jiangsu Caiwei Biotechnology Co., Ltd.): nanometer Copper Oxide Mimic Enzyme: Sodium Lauroyl Glutamate: Maleic Anhydride Grafted Polyethylene: Zinc Stearate: Hydrotalcite: Methyl Vinyl Ether Maleic Anhydride Copolymer: Sodium Saccharin: Mixed Polyol: Mixed Polyacid: The mass ratio of compatibilizer: plasticizer: antioxidant is: 20: 0.2: 0.004: 0.004: 0.3: 1.5: 1: 0.2: 0.003: 5: 5: 2: 5: 0.002;

[0052] The mixed polyol is a mixture of equimolar amounts of 1,5-pentanediol, 4-methyl-2,3-pentanediol, sorbitol, isosorbide and maltitol;

[0053] Described mixed polybasic acid is the mixture of succinic acid, maleic acid, oxalic acid, adi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com