Hybrid cross-linked dynamic polymer and application thereof

A hybrid cross-linking and polymer technology, applied in the field of intelligent polymers, can solve the problems of stimulation, limited dynamic effect and dynamic control ability, and inability to combine structural and dynamic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

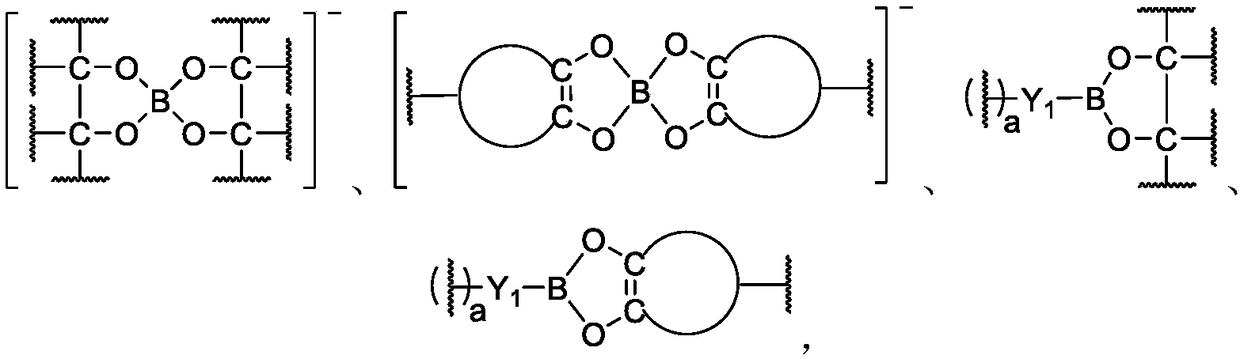

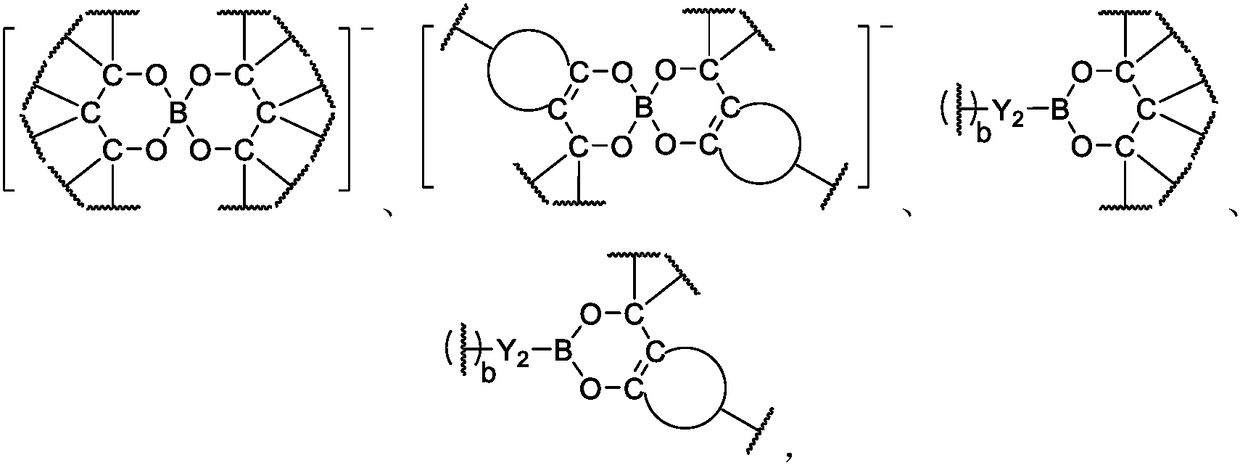

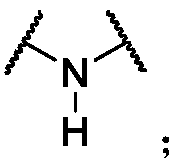

[0201] In the preparation process of dynamic polymers, for dynamic polymers containing only one crosslinking network (this crosslinking network contains both dynamic covalent crosslinks and common covalent crosslinks), it can utilize at least one inorganic boron compound ( I) and at least one dihydroxy compound (II) participate in the reaction to generate an inorganic boronic acid ester bond and a common covalent bond to obtain hybrid crosslinking; or utilize at least one compound (III), or combine it with at least one compound ( IV) Participate in the reaction to form ordinary covalent bonds and perform hybrid cross-linking; wherein, at least one inorganic boron compound (I) or at least one dihydroxy compound (II) contains one or more other reactive groups.

[0202] For dynamic polymers with two cross-linked networks (one with only normal covalent cross-links and the other with only dynamic covalent cross-links), the network structure contains only normal covalent cross-links ...

Embodiment 1

[0283] Use pentaerythritol and 3-bromopropionic acid as raw materials, control the molar ratio of the two to 1:4, obtain pentaerythritol 3-bromopropionate through esterification, and react it with an equimolar amount of sodium azide to prepare pentaerythritol tetraazide.

[0284] Using dicyclohexylcarbodiimide and 4-dimethylaminopyridine as catalysts, polyamide with a molecular weight of about 5,000 is sequentially reacted with equimolar amounts of 5-alkynylhexanoic acid and propargyl alcohol through amidation and esterification reactions Alkyne-terminated polyamides are obtained.

[0285] Using 4-hydroxystyrene and formaldehyde as raw materials, reflux them with zinc nitrate hexahydrate for 24 hours to synthesize 2-(hydroxymethyl)-4-vinylphenol, then use methanol as solvent, AIBN as initiator, triethylamine As a catalyst, polyol compound can be obtained by reacting it with pentaerythritol tetramercaptoacetate through mercaptan-alkene click addition reaction.

[0286] Add a ...

Embodiment 2

[0289] Using 3-(allyloxy) 1,2-propanediol and hydrogen-terminated siloxane with a viscosity of about 6000mPa·s as raw materials, it is prepared by hydrosilylation under the catalytic conditions of platinum ene complex Pt(dvs). In two hydroxyl end-capped siloxane.

[0290] Using octamethylcyclotetrasiloxane and phenyltris(dimethylsiloxane)silane as raw materials and concentrated sulfuric acid as a catalyst, a three-terminal hydropolysiloxane is prepared by ring-opening polymerization.

[0291]Add 200ml of dioctyl phthalate, 4mmol of three-terminal hydrogen polysiloxane, and 12mmol of double-terminal unsaturated polyether with a molecular weight of about 1000 to a dry and clean three-necked flask, and pass nitrogen gas to remove water and oxygen for 20 minutes. Heat to 40°C for stirring and dissolving, add 1ml of 1% Pt(dvs)-THF solution as a catalyst, react for 30h under nitrogen protection conditions, and form a cross-linked network; then add 0.02mol of tris(trimethylsilyl) bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com