Flame-retardant mould-proof thermoplastic polyurethane elastomer composite material and preparation method thereof

A thermoplastic polyurethane and composite material technology, applied in the field of polyurethane elastomers, can solve the problems of reduced service life of polyurethane, no flame retardancy, bacteria generation, etc., to reduce resin consumption, improve mildew resistance, and improve tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

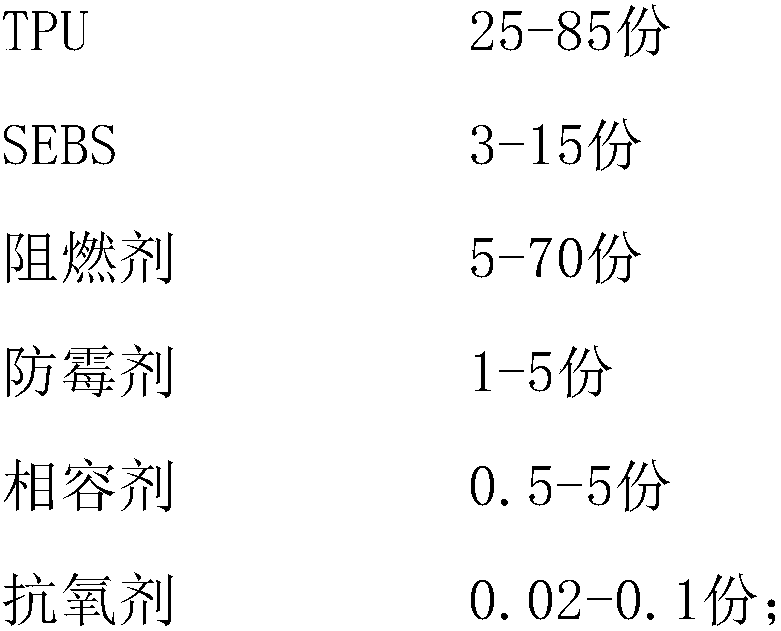

[0051] A flame-retardant anti-mold polyurethane elastomer composite material, comprising the following raw materials in parts by weight:

[0052]

[0053]

[0054] Wherein, the SEBS is maleic anhydride graft modified SBES.

[0055] The TPU is a polyether polyurethane with a hardness of 70A.

[0056] The SEBS is a styrene-ethylene-butylene-styrene block copolymer with a styrene unit content of 40%, an ethylene unit content of 30%, and a butene unit content of 30%; the maleic anhydride graft modification The grafting rate of permanent SBES was 0.5%.

[0057] The flame retardant is a halogen-free flame retardant, and the halogen-free flame retardant is ammonium phosphate, ammonium polyphosphate, modified ammonium polyphosphate or aluminum hypophosphite.

[0058] The antifungal agent is silver ion antibacterial agent, copper ion antibacterial agent or zinc ion antibacterial agent.

[0059] The compatibilizer is polyurethane prepolymer modified maleic anhydride grafted pol...

Embodiment 2

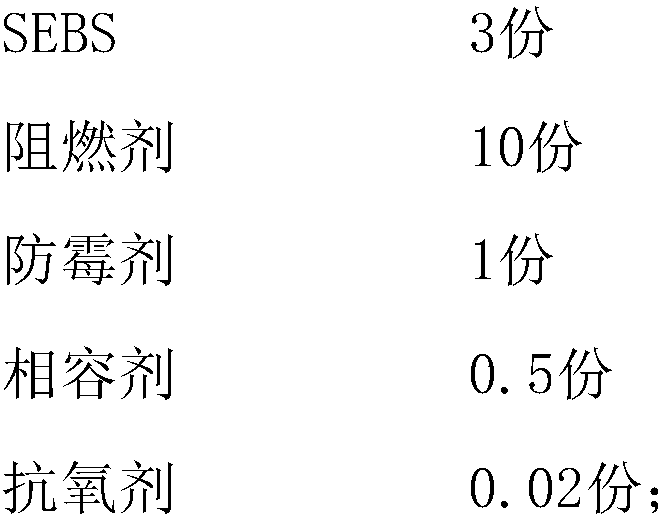

[0067] A flame-retardant anti-mold polyurethane elastomer composite material, comprising the following raw materials in parts by weight:

[0068]

[0069] Wherein, the SEBS is maleic anhydride graft modified SBES.

[0070] The TPU is polyester polyurethane with a hardness of 75A.

[0071] The SEBS is a styrene-ethylene-butylene-styrene block copolymer with a styrene unit content of 45%, an ethylene unit content of 27.5%, and a butene unit content of 27.5%; the maleic anhydride graft modified The grafting rate of permanent SBES was 0.8%.

[0072] The flame retardant is a mixture of a halogen-containing flame retardant and a synergistic flame retardant at a weight ratio of 1:1; the halogen-containing flame retardant is 2,6-dibromophenylene ether, tetrabromobisphenol A , hexabromocyclododecane, octabromoether, decabromodiphenylethane or polypentabromophenol-based acrylate; the synergistic flame retardant is antimony trioxide, bismuth trioxide, molybdenum trioxide or three f...

Embodiment 3

[0082] A flame-retardant anti-mold polyurethane elastomer composite material, comprising the following raw materials in parts by weight:

[0083]

[0084] Wherein, the SEBS is maleic anhydride graft modified SBES.

[0085] The TPU is polycarbonate polyurethane with a hardness of 80A.

[0086] The SEBS is a styrene-ethylene-butylene-styrene block copolymer with a styrene unit content of 50%, an ethylene unit content of 25%, and a butene unit content of 25%; the maleic anhydride graft modification The grafting rate of permanent SBES was 1.2%.

[0087] The flame retardant is a halogen-free flame retardant; the halogen-free flame retardant is melamine and its compounds, zinc borate, montmorillonite, clay or metal hydroxide.

[0088] The antifungal agent is 2-thiazol-4-ylbenzimidazole or 10,10'-oxobisphenoxarsen.

[0089] The compatibilizer is γ-glycidyl etheroxypropyl trimethoxysilane, γ-methacryloxypropyl-trimethoxysilane or N-(β-aminoethyl)-γ-aminopropyl -Methyl-trimethox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com