Deodorant used for removing volatile stink of feces and preparation and application thereof

A deodorant and volatile technology, which are applied in the field of deodorant of fecal volatile odorous gas and its preparation field to achieve the effects of low cost and excellent deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of porous hydroxyapatite

[0032] i) Take Tween-80 and add 100ml concentration of 0.5% toluene, shake and shake, add 50ml1mol / L sodium carbonate solution, ultrasonic emulsification for 15min, pour the emulsion into 300ml 0.2mol / L calcium chloride solution, Stir and react for 2 hours, age for 24 hours, filter the aged solution with suction to obtain a white precipitate, wash with distilled water and absolute ethanol for 3 times, dry at 80°C for 12 hours, and obtain porous spherical calcium carbonate powder;

[0033] ii) Take the above-mentioned porous spherical calcium carbonate powder and add purified water to form a suspension of 0.05 g / ml. Under stirring conditions, add 0.03 mol / L disodium hydrogen phosphate solution to keep the pH at 11, stir for 12 hours, and age for 24 hours; filter the aged solution with suction to obtain a white precipitate, wash with distilled water and absolute ethanol three times, dry at 80°C for 12 hours, and ca...

Embodiment 2

[0034] Embodiment 2, preparation of anode furnace refining slag

[0035] S1. Sintering: take the copper-containing sludge and carry out sintering, move the sintered block into the smelting furnace, add limestone 10kg / t Cu, carbon fine 3kg / t Cu, and at the same time, continue to feed air containing 25% (v / v) oxygen Carrying out calcination to obtain blister copper, wherein the calcination temperature is 1100°C;

[0036] S2. Refining: move the above-mentioned blister copper into the refining furnace, add 3kg / t Cu heavy oil, and at the same time continue to feed air containing 95% (v / v) oxygen to mix the blister copper, add carbon powder 2kg / t Cu and 4kg / t Cu quartz stone to obtain anode copper plate and anode furnace refining slag, in which the calcining temperature is 1200°C.

[0037] The prepared anode furnace refining slag mainly includes the following components by weight: CaO 6.2-8.3wt%, SiO 2 25.6~29.2wt%, Al 2 o 3 6.3~9.4wt% and FeO 25.4~35.8wt%.

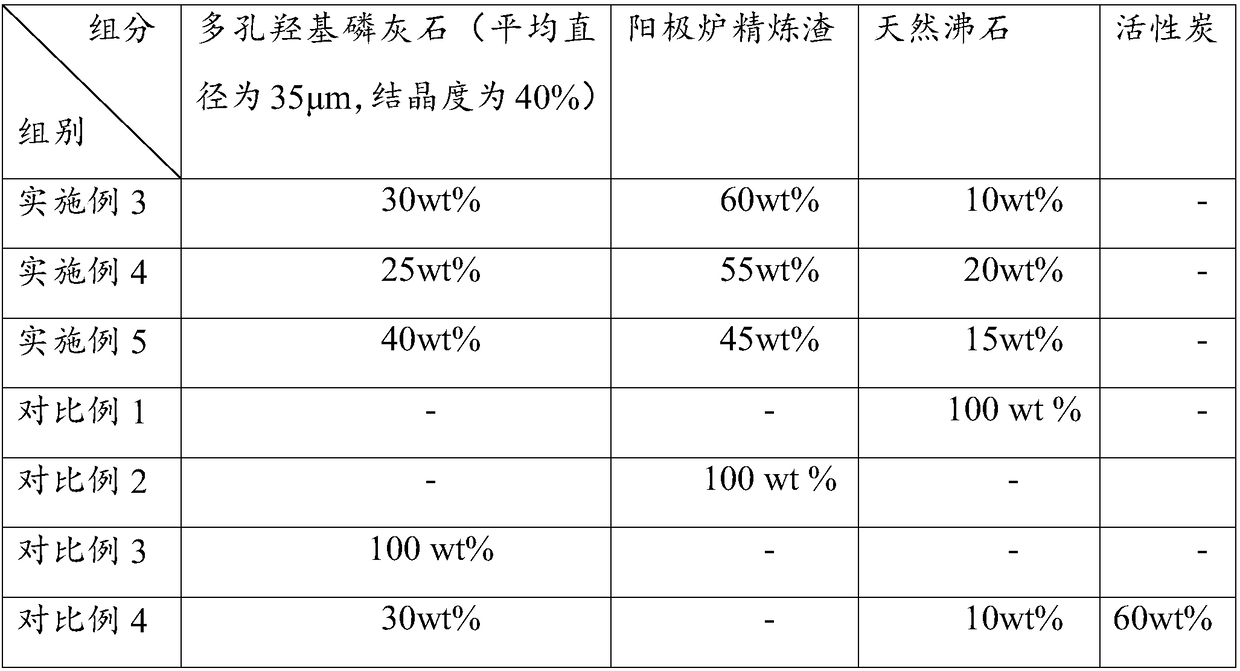

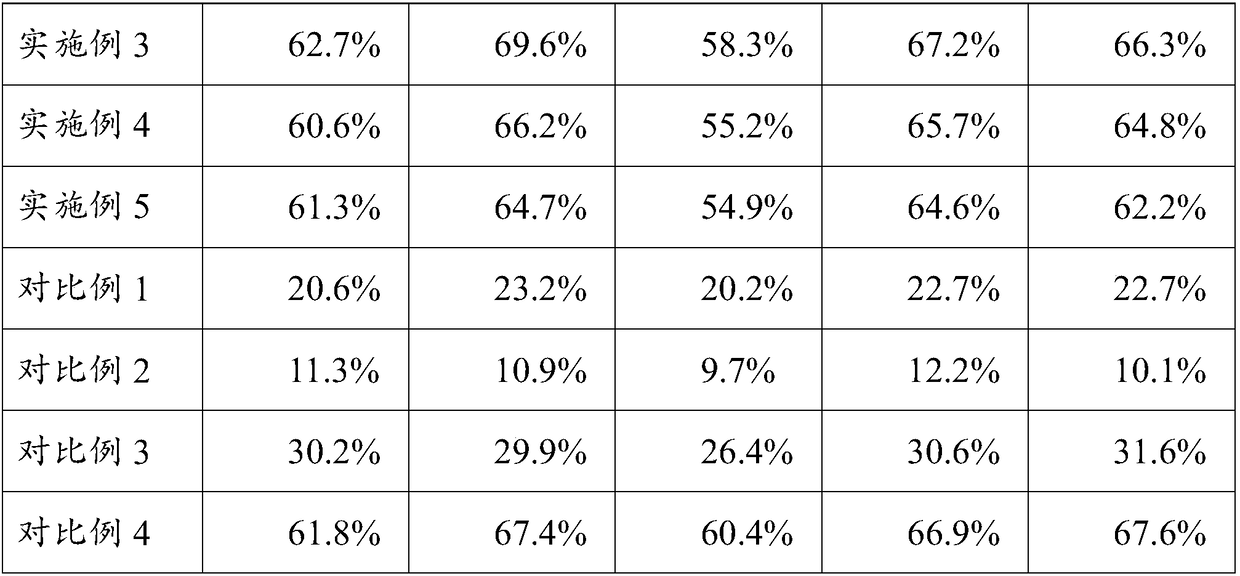

[0038] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com