A kind of electrolytic polishing equipment for inner wall of stainless steel pipe

A technology of electrolytic polishing and stainless steel tubes, applied in electrolytic components, electrolytic process, etc., can solve the problems of deteriorating air bubble outflow effect, failure to reach current density, hidden danger of large water pollution, etc., achieve good process stability and consistency, and economic benefits Good safety and prevent running, emitting, dripping and leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

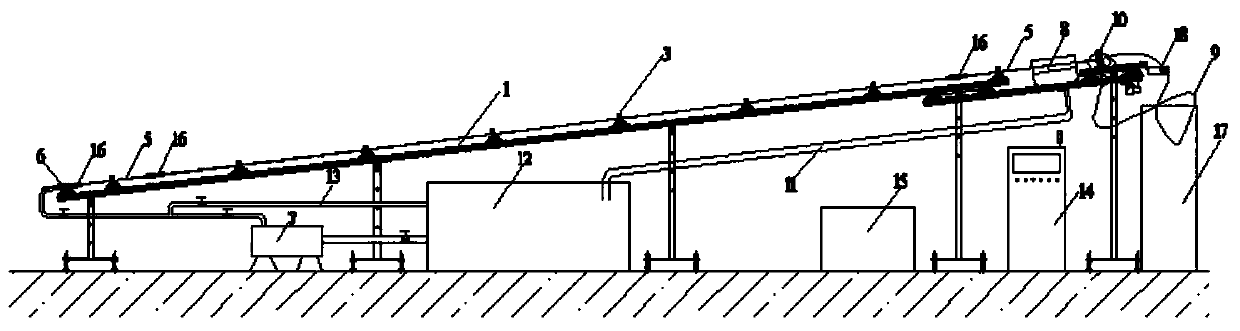

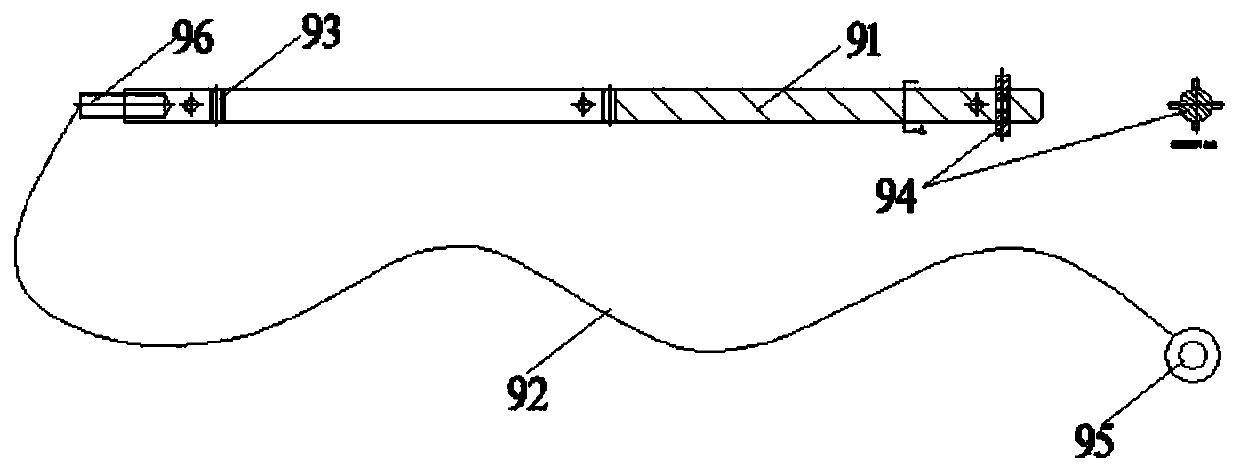

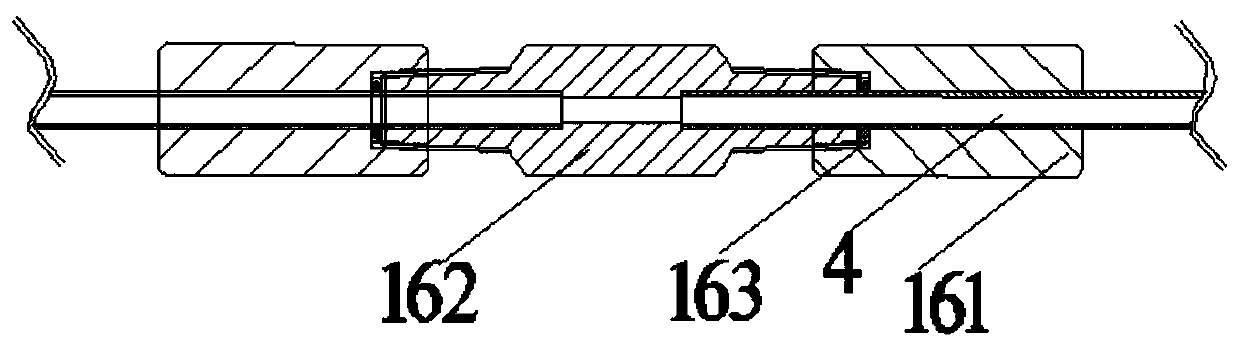

[0056] An electrolytic polishing equipment used for the inner wall of stainless steel pipes, the upper end of the equipment is equipped with a copper anode assembly frame 1, the inclination angle of the copper anode assembly frame 1 is 5-15°, and 10 to 20 anodes can be placed at one time product, the bottom of the copper anode assembly frame 1 is equidistantly provided with several brackets to fix the equipment, and the copper anode assembly frame 1 is provided with several V-shaped grooves 2, which are suitable for steel pipe products with various outer diameters , a pressing device 3 is arranged on the upper part of the V-shaped groove 2, a steel pipe 4 is arranged between the copper anode assembly frame 1 and the pressing device 3, and two ends of the steel pipe 4 are connected with extending Steel pipe 5, the diameter of the extension steel pipe 5 is the same as that of the steel pipe 4, the extension steel pipe 5 is 50-100cm long, and the left end of the extension steel pi...

Embodiment 2

[0070] 1. Example of production of 316L stainless steel pipe with an outer diameter of 12.7 mm (1 / 2 inch):

[0071] 1.1. Place 10 316L raw material steel pipes with an outer diameter of 12.7 millimeters and a length of 6 meters on the copper anode assembly frame at one time (the raw material pipes are processed by bright annealing);

[0072] 1.2. The upper and lower ports of all steel pipes are connected with 304 extended steel pipes with a length of 800 mm and an outer diameter of 12.7 mm using the quick-twist joint assembly. There are 10 extension steel pipes at the top and bottom respectively, and the 10 extension steel pipes at the lower end are connected to the electrolyte distributor through the quick-twist joint assembly. The steel pipe extended at the upper end extends into the collector, and the upper port is opened.

[0073] 1.3. Select the round copper rod with a diameter of 5 mm and a length of 800 mm as the cathode body. A PTFE externally threaded rod with a dia...

Embodiment 3

[0077] Embodiment 3: Effect embodiment of product or method

[0078] In the above-mentioned Example 2, ten 316L stainless steel pipes with a length of 6 meters were electrolyzed within 30 minutes, and a series of inspections were carried out after the conventional cleaning process was completed.

[0079] 1. The inner surface roughness of three positions at both ends and the center of each steel pipe is tested. Each position is tested at two points by Mitutoyo SJ-210 roughness meter. The actual measured inner surface roughness data is as follows: Figure 8 shown.

[0080] 2. All the steel pipes are cut open for visual inspection. The inner walls of the steel pipes are bright and electrolytically polished without any visible defects.

[0081] 3. Based on the international standard test method SEMATECH Test Method 91060573B in the semiconductor industry, the AES oxide layer thickness analysis of the steel pipe sample is carried out, and the results are as follows Figure 9 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com