Preparation method for cadmium sulfide based composite catalyst capable of processing industrial wastewater

A composite catalyst and industrial wastewater technology, applied in the chemical field, can solve the problems of lack of environmental engineering stability performance, catalyst recycling rate reduction, etc., achieve good cycle stability and recycling rate, excellent photogenerated carrier separation efficiency, resist Effects of Photocorrosion and Chemical Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a cadmium sulfide-based composite catalyst capable of treating industrial wastewater, comprising the following steps:

[0039] Step 1, add a certain amount of hydroxypropyl cellulose to 1000 ml of absolute ethanol solution, keep stirring for 1-6 hours, then add 10 ml of deionized water, and keep stirring for 30 minutes; Step 2, add 4-8 Milliliters of tetrabutyl titanate, continuously stirred for 30 minutes, centrifuged after standing for 6-10 hours to obtain titanium dioxide nanospheres, and washed 3-5 times with ethanol and deionized water successively; Step 3, the titanium dioxide nanospheres Add it to a certain amount of sodium hydroxide solution, stir for 2 hours, take it out and wash it with water; step 4, add titanium dioxide nanospheres to a certain amount of cadmium chloride solution, keep stirring for 1-2 hours, and then add A certain amount of sodium sulfide solution, continue to stir for 1-2 hours, take out and wash with water and dry...

Embodiment 1

[0044] The specific implementation method of the control experiment is as follows:

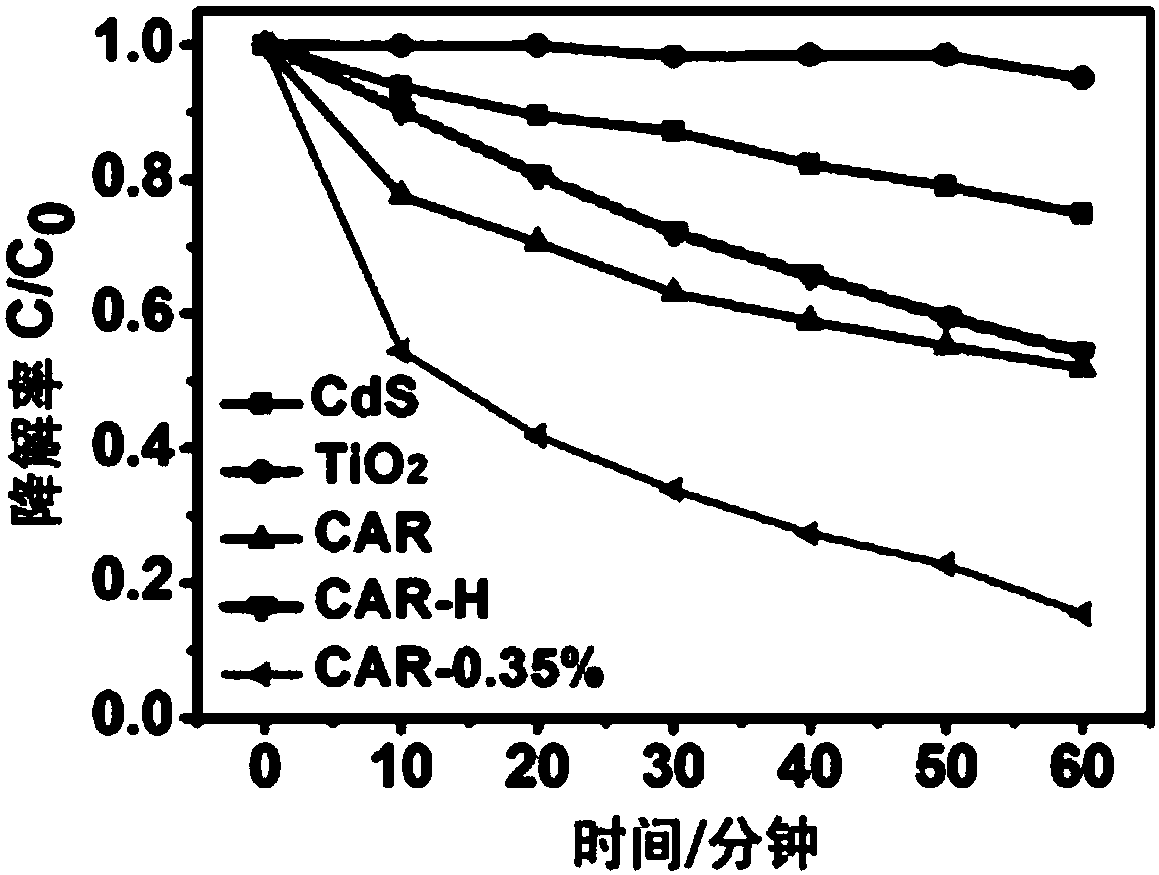

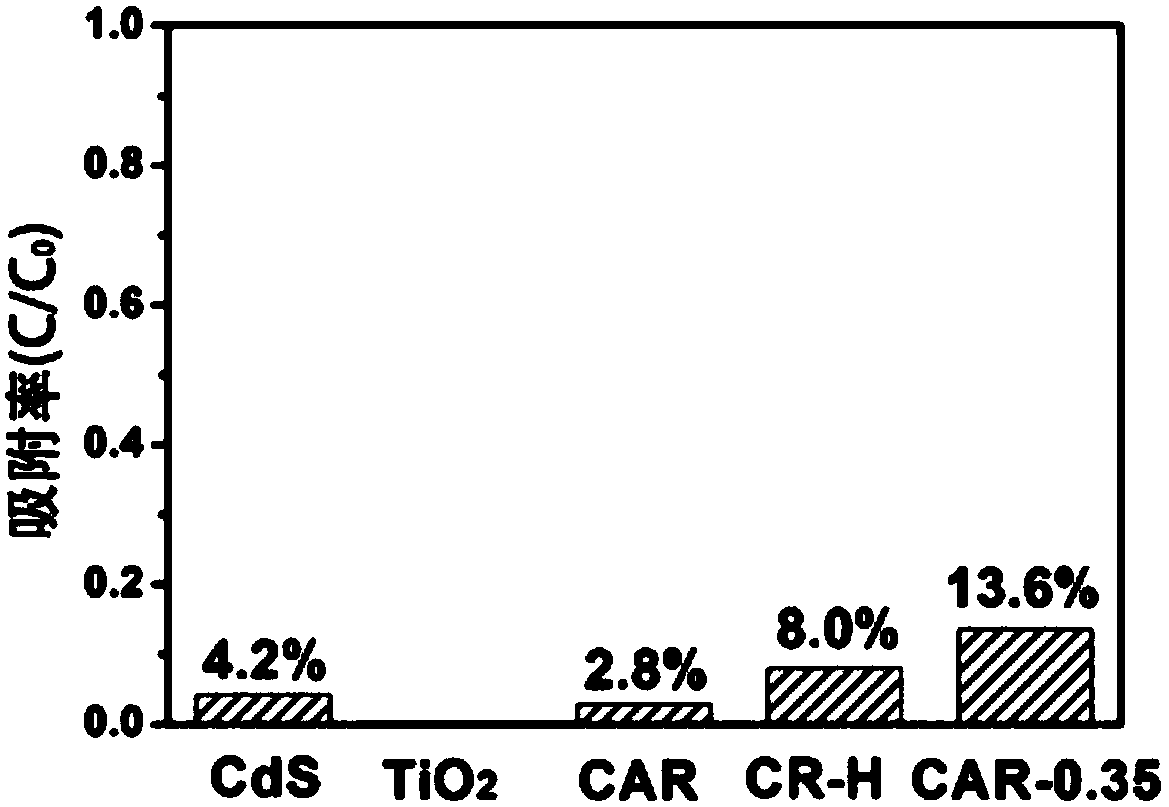

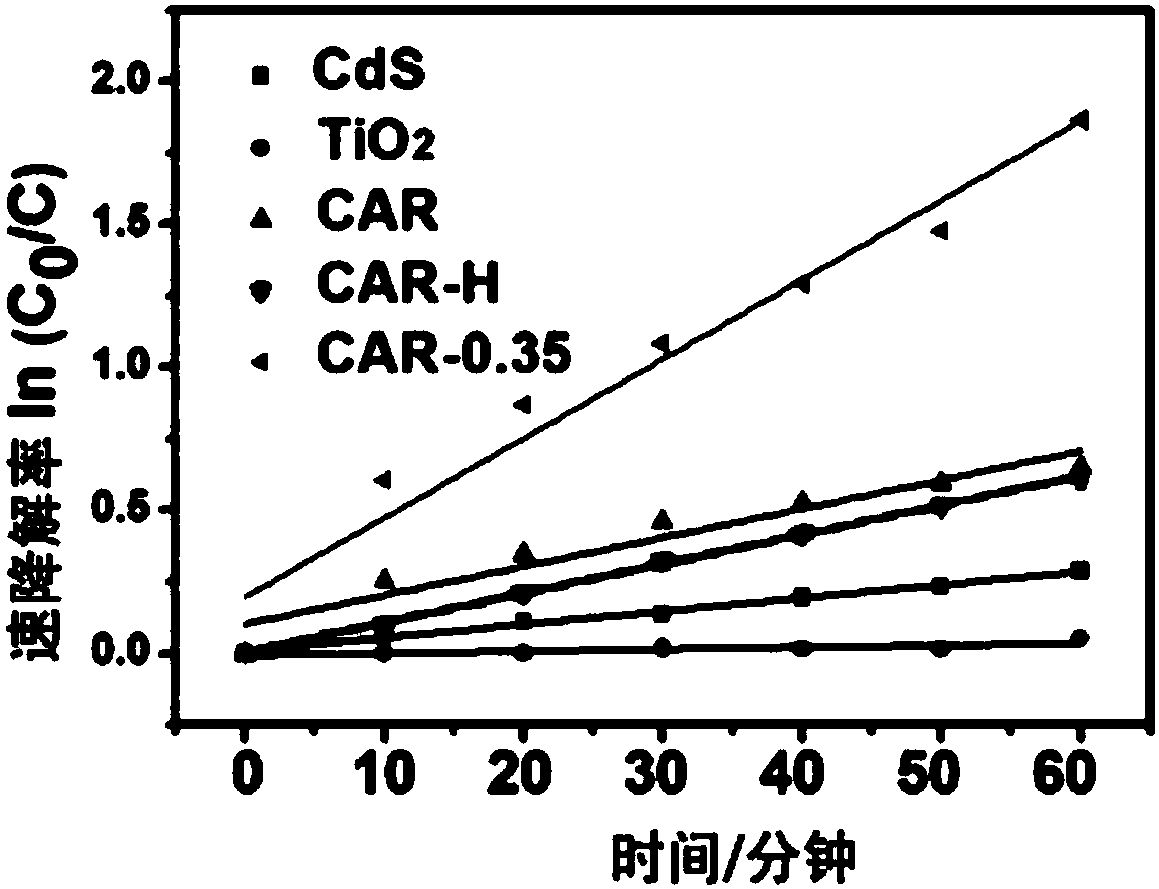

[0045] (1) 50 mL of rhodamine B dye solution to be treated, 50 mg of cadmium sulfide, titanium dioxide, CAR, CAR-H and CAR-0.35% catalyst were added respectively, and after 30 minutes of dark adsorption, the rhodamine B dye was degraded under visible light irradiation, wherein CAR Indicates cadmium sulfide-based (without strong acid immersion) composite catalyst, CAR-H indicates cadmium sulfide-based (without using sodium hydroxide as pretreatment) composite catalyst, CAR-0.35% indicates cadmium sulfide-based (final sample soaked in strong acid overnight) composite catalyst;

[0046] (2) The cycle stability performance of cadmium sulfide, CAR, CAR-H and CAR-0.35% was tested under neutral conditions, and the number of cycle tests was 5 times. Add 50 mg of catalyst to 50 mL of dye solution, and after 30 minutes of dark adsorption, degrade Rhodamine B dye under visible light irradiation. After e...

Embodiment 2

[0050] The treatment steps for acid mineral wastewater are as follows: configure acid mineral wastewater containing different concentrations of heavy metal ions, and the concentrations of its components are Fe 2+ =1004.35mg / L, Fe 3+ =998.43mg / L, Al 3+ =500.51mg / L, Mn 2+ =292.54mg / L, Cu 2+ =25.45mg / L, Zn 2+ =143.92mg / L, Ni 2+ =98.77mg / L, Cd 2+ = 18.22 mg / L. The acid mineral wastewater had an initial pH value of 1.97. Add 50 mg CAR-0.35% composite catalyst to 50 mL of the prepared acidic mineral wastewater, and then irradiate under visible light for 10 hours after dark adsorption for 30 minutes.

[0051] The experimental results are shown in the table below and figure 2 As shown, under the original pH=1.97 condition of acid mineral wastewater, Fe 2+ / Fe 3+ 、Al 3 + , Mn 2+ 、Cu 2+ , Zn 2+ 、Ni 2+ and Cd 2+ The ion removal effects can reach 81.53%, 93.41%, 52.12%, 66.60%, 43.02%, 69.62% and 61.03%, respectively. However, under the condition of pH=3.5, the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degradation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com