Electronic insulating encapsulating material and preparation method thereof

A packaging material, electronic insulation technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of poor mechanical properties of insulating packaging materials, affecting the service life of electronic components, and cumbersome manufacturing methods, etc. Achieve the effect of favorable heat dissipation, high hardness, improved thermal conductivity and insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

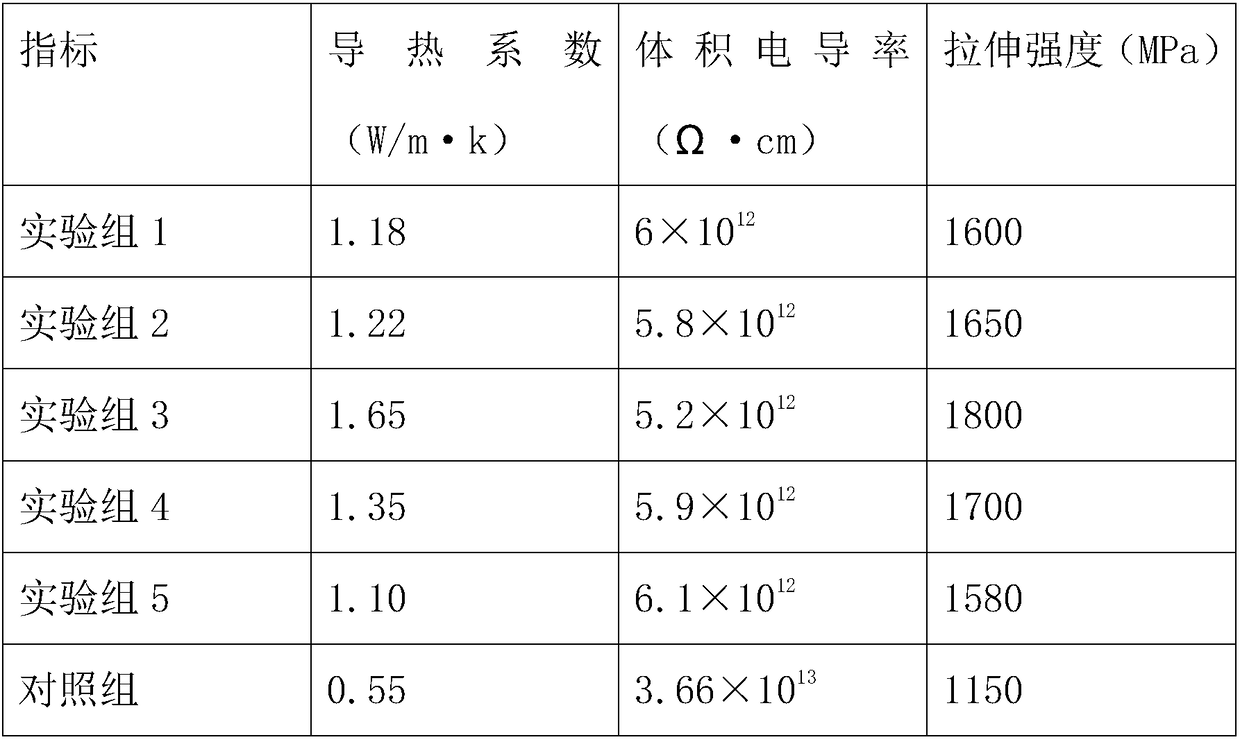

Examples

Embodiment 1

[0023] This embodiment provides an electronic insulating packaging material, which includes the following raw materials in parts by weight: 10 parts of diamond, 20 parts of silicon carbide, 10 parts of carbon fiber, 15 parts of epoxy resin, and 20 parts of thermally conductive inorganic nanoparticles , 10 parts of anti-corrosion agent, 10 parts of toughening agent, 20 parts of polyamide, 30 parts of matrix, 10 parts of graphite.

[0024] Among them, the carbon fiber is made by carbonizing viscose silk, polyacrylonitrile fiber and pitch silk at 1000°C, the length of the carbon fiber is 45mm, the epoxy resin is bisphenol A epoxy resin, and the thermally conductive inorganic nanoparticles are alumina, oxide The mixture of zinc and magnesium oxide, the mixing ratio is 1:2:3, the toughening agent includes the following raw materials in parts by weight: 10 parts of carboxyl liquid nitrile rubber, 20 parts of carboxyl-terminated liquid nitrile rubber, 5 parts of polysulfide rubber, 2...

Embodiment 2

[0031] This embodiment provides an electronic insulating packaging material, which includes the following raw materials in parts by weight: 15 parts of diamond, 30 parts of silicon carbide, 20 parts of carbon fiber, 30 parts of epoxy resin, and 30 parts of thermally conductive inorganic nanoparticles , 20 parts of anti-corrosion agent, 15 parts of toughening agent, 25 parts of polyamide, 40 parts of matrix, 15 parts of graphite.

[0032] Among them, the carbon fiber is made by carbonizing viscose yarn, polyacrylonitrile fiber and pitch yarn at 3000°C. The length of the carbon fiber is 55 mm. The epoxy resin is bisphenol F epoxy resin. The toughening agent includes the following raw materials in parts by weight: 15 parts of carboxyl liquid nitrile rubber, 25 parts of carboxyl-terminated liquid nitrile rubber, 10 parts of polysulfide rubber, 25 parts of liquid silicone rubber, 16 parts of polyether, 25 parts of polysulfone, polyamide 20 parts of imine, 25 parts of nano-calcium c...

Embodiment 3

[0039] This embodiment provides an electronic insulating packaging material, which includes the following raw materials in parts by weight: 12 parts of diamond, 25 parts of silicon carbide, 15 parts of carbon fiber, 22 parts of epoxy resin, and 25 parts of thermally conductive inorganic nanoparticles , 15 parts of anti-corrosion agent, 12 parts of toughening agent, 22 parts of polyamide, 35 parts of matrix, 12 parts of graphite.

[0040]Among them, the carbon fiber is formed by carbonizing viscose yarn, polyacrylonitrile fiber and pitch yarn at 2000°C, the length of the carbon fiber is 50 mm, the epoxy resin is bisphenol F epoxy resin, and the thermally conductive inorganic nanoparticles are alumina, oxide The mixture of zinc, magnesium oxide and boron nitride, the mixing ratio is 2:1:1:2, the toughening agent includes the following raw materials in parts by weight: 12 parts of carboxyl liquid nitrile rubber, 22 parts of carboxyl-terminated liquid nitrile rubber, 7 parts of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com