Electrode unit and electrode prepared therefrom

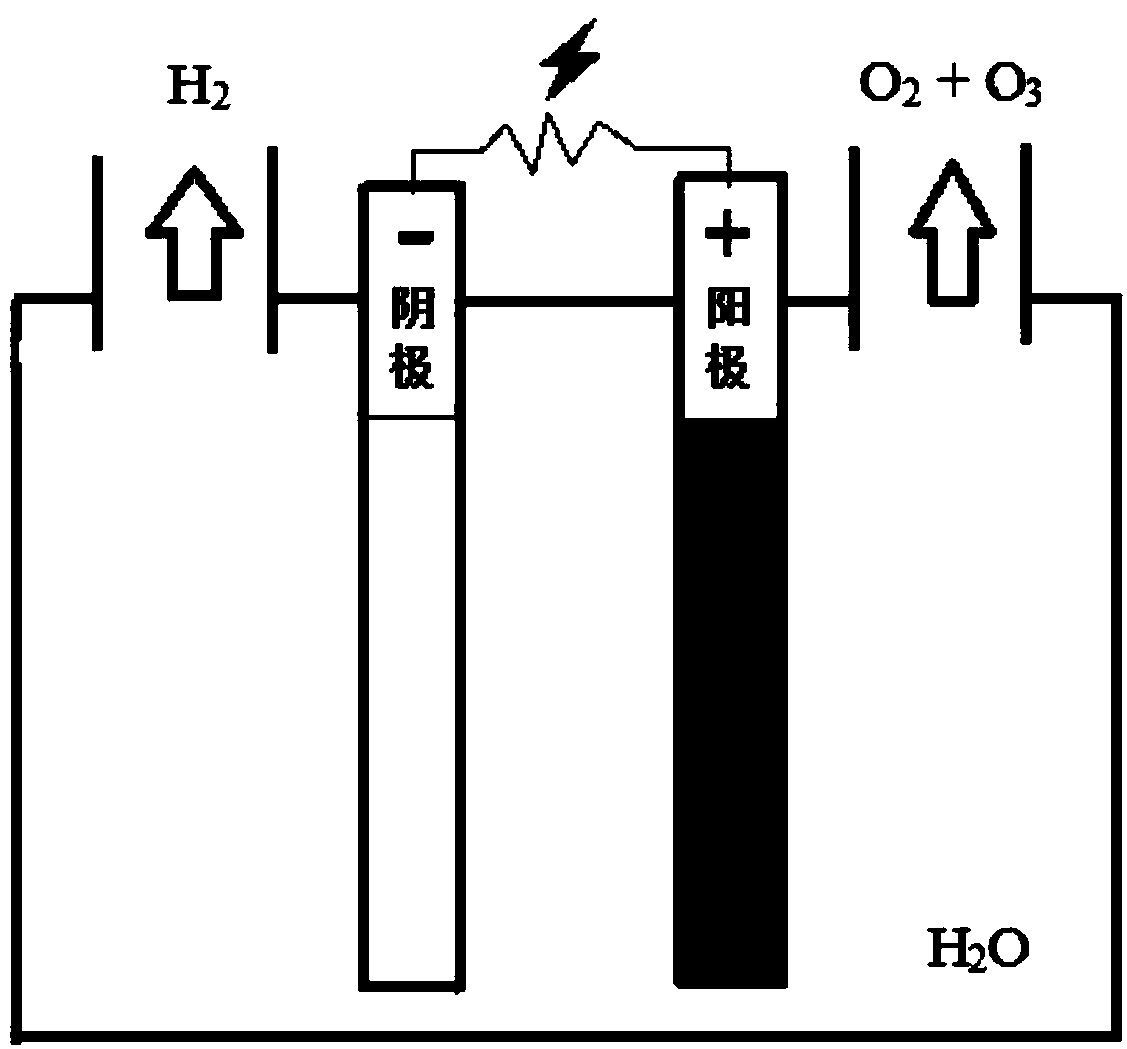

An electrode unit, electrode technology, applied in the direction of electrodes, electrical components, electrolysis components, etc., can solve the problems of easy recrystallization, decreased ozone current efficiency, corrosion, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 conductive diamond particle

[0048] Under the condition of high temperature and high pressure (above 500°C, exceeding 10GPa), the catalyst / graphite / boron source is taken through the oil pressure mechanism to obtain conductive diamond particles, and then broken up by physical means to obtain small conductive diamond particles; or directly use high temperature and high pressure (above 500°C, exceeding 10GPa) method to prepare conductive small diamond particles, and the wire diameter of the obtained diamond particles is 4nm-1mm.

Embodiment 2

[0049] The preparation of embodiment 2 conductive diamond particles

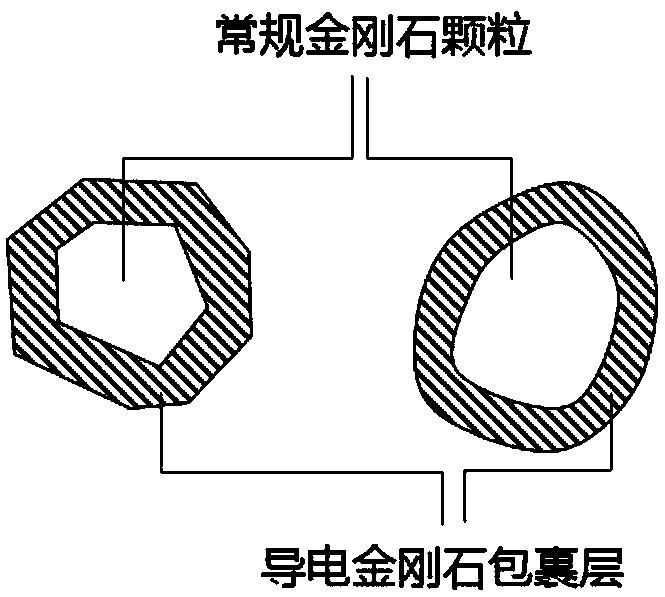

[0050] Use the hot wire chemical vapor deposition method to deposit CVD conductive diamond coating on the conventional high temperature and high pressure diamond particles, choose the common type IIb diamond particles that are not conductive themselves, the wire diameter is 4nm ~ 1mm, first use hydrogen peroxide, nitric acid, pure water respectively , alcohol, etc., and then placed in a hot-wire chemical vapor deposition equipment for growth. The growth conditions are as follows: abutment temperature 500-800°C, hot-wire temperature 180-2400°C, air pressure 1-5kPa, hydrogen gas 100- 1000SCCM, methane 1-20SCCM, borane 1-20SCCM, grow for more than 10 minutes, form a conductive diamond coating layer on the above-mentioned diamond particles, the thickness of the coating layer is 4nm-10μm, that is, form a composite structure of surface conductive diamond particles, Such as figure 2 shown.

Embodiment 3

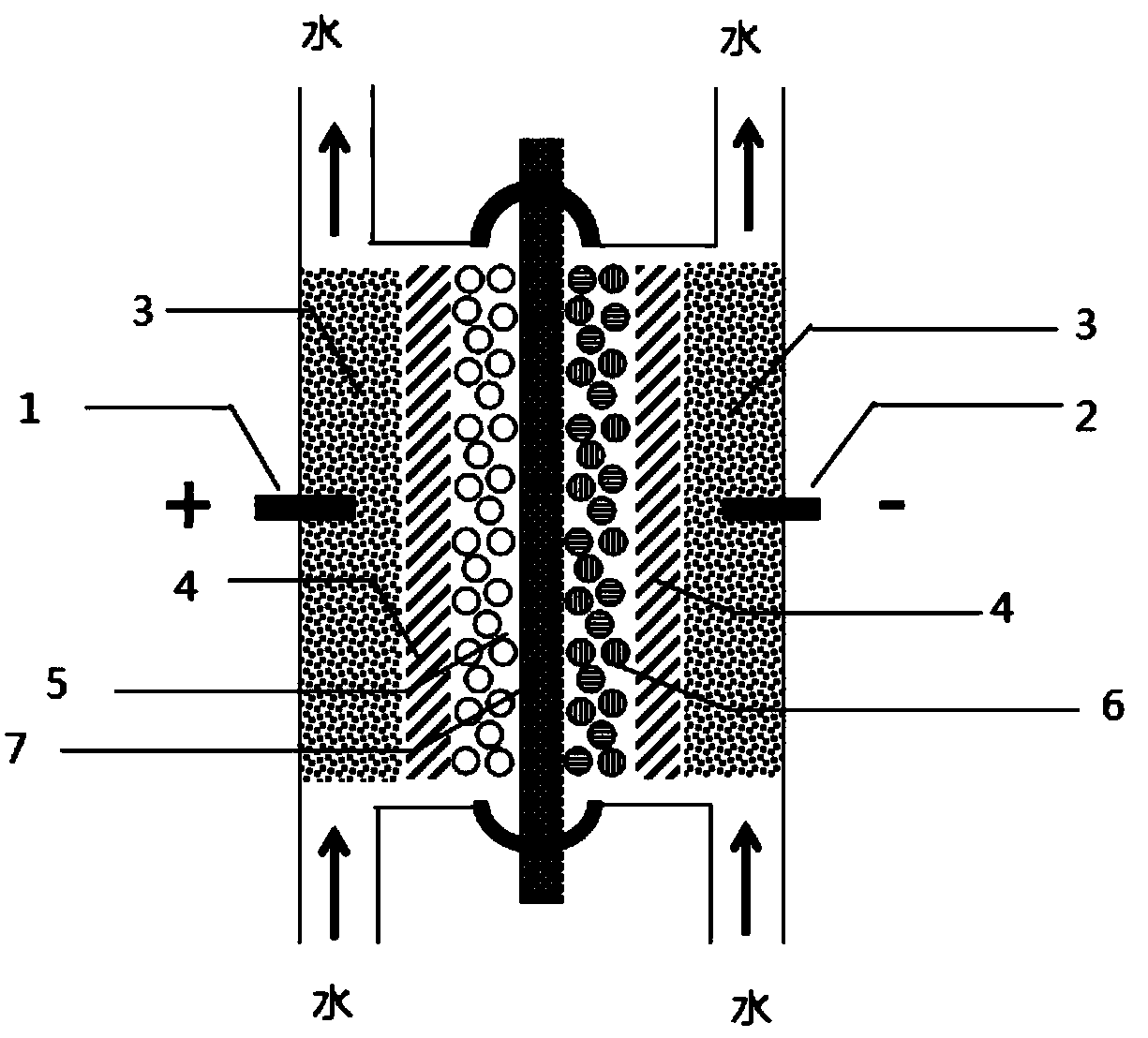

[0051] Embodiment 3 Conductive diamond particle is the preparation of the electrode of anode

[0052] 1. Pretreatment of PEM membrane (DuPont Nafion117 membrane): (1) HNO with a volume ratio of 1:1 3 -H 2 O or H with a mass concentration of 5% to 10% 2 o 2 Boil in medium for 30 minutes to remove impurities on the membrane and organic matter on the surface of the membrane; (2) in 0.5mol of H 2 SO 4 Boil in medium for 30 minutes to remove metal impurities; (3) then place the membrane in boiling deionized water for 1 hour to remove excess acid and introduce renewable amounts of water into the membrane; (4) finally place the pretreated PEM membrane Store in deionized water until use.

[0053] 2. Make the conductive diamond particle anode on one side of the pretreatment PEM film, and use the conductive diamond particle, deionized water, ethanol, glycerin and Nafion solution made in Example 1 by ultrasonic oscillation, according to the weight ratio of 0.5:1:1:0.5 : 0.4 uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com