Preparation method and application of composite cathode plate rich in Li-rich manganese base

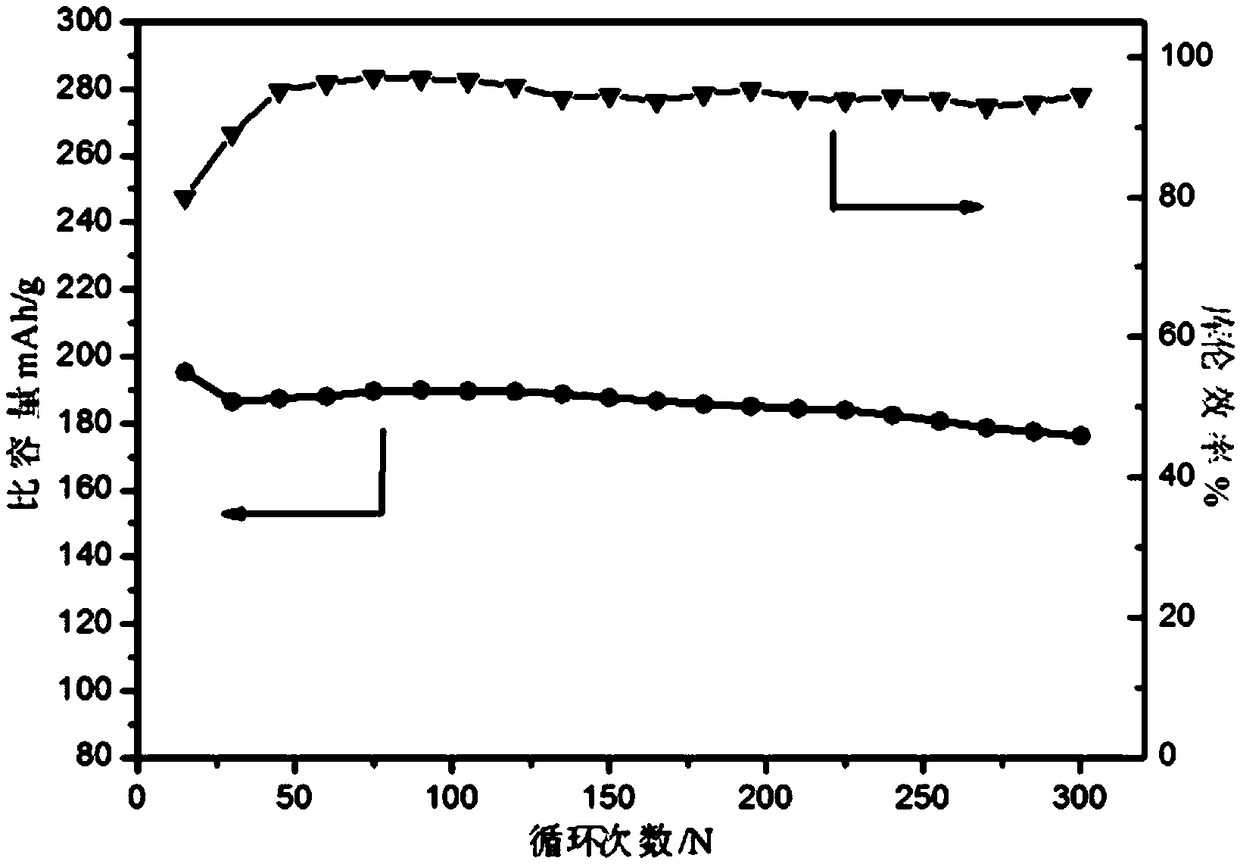

A composite positive electrode, lithium-rich manganese-based technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor rate performance and cycle life, large irreversible capacity loss, fast voltage decay, etc., to achieve a single device , powder crystallinity and dispersion, low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a lithium-rich manganese-based composite positive electrode sheet, the preparation method comprising the following steps: Step 1: dissolving 2 parts by mass of glucose in deionized water;

[0022] Step 2: Add 100 parts by mass of lithium-rich manganese base and dissolved glucose solution into the hydrothermal reaction kettle, heating at 120°C for 4 hours;

[0023] Step 3: Take out the cooled mixed solution and filter with suction, and dry the filtered powder at 70°C for 4 hours;

[0024] Step 4: Take 80 parts by mass of lithium-rich manganese-based powder coated with an organic carbon source, 2 parts by mass of Surpe-P, 2 parts by mass of polyvinylidene fluoride, and 2 parts by mass of lithium lanthanum zirconium oxide (LLZO) and 3 parts by mass of LiTFSI are uniformly mixed and dispersed in N-methylpyrrolidone solvent, and fully stirred with a vacuum planetary mixer to obtain a composite positive electrode slurry;

[0025] Step 5: Use a coating ...

Embodiment 2

[0028] A method for preparing a lithium-rich manganese-based composite positive electrode sheet, the preparation method comprising the following steps: Step 1: dissolving 4 parts by mass of sucrose in deionized water;

[0029] Step 2: Add 100 parts by mass of lithium-rich manganese base and dissolved sucrose solution into a hydrothermal reaction kettle, heat at 150°C for 4 hours;

[0030] Step 3: Take out the cooled mixed solution and filter with suction, and dry the filtered powder at 80°C for 8 hours;

[0031] Step 4: Take 85 parts by mass of lithium-rich manganese-based powder coated with an organic carbon source, 2 parts by mass of acetylene black, 3 parts by mass of polyvinylidene fluoride-hexafluoropropylene, and 3 parts by mass of lithium lanthanum titanium oxide (LLTO) and 3 parts by mass of LiClO mixed uniformly and dispersed in N-methylpyrrolidone solvent, fully stirred with a vacuum planetary mixer to obtain composite positive electrode slurry;

[0032] Step 5: Use...

Embodiment 3

[0035] A method for preparing a lithium-rich manganese-based composite positive electrode sheet, the preparation method comprising the following steps: Step 1: dissolving 5 parts by mass of citric acid in deionized water;

[0036] Step 2: Add 100 parts by mass of lithium-rich manganese base and dissolved citric acid solution into the hydrothermal reaction kettle, heating at 180°C for 6 hours;

[0037] Step 3: Take out the cooled mixed solution and filter with suction, and dry the filtered powder at 80°C for 8 hours;

[0038] Step 4: Take 90 parts by mass of lithium-rich manganese-based powder coated with an organic carbon source, 3 parts by mass of graphene, 4 parts by mass of polytetrafluoroethylene, and 6 parts by mass of lithium lanthanum zirconium tantalum oxide (LZTO) and 6 parts by mass of LiPF6 mixed uniformly and then dispersed in N-methylpyrrolidone solvent, fully stirred uniformly with a vacuum planetary mixer to obtain a composite positive electrode slurry;

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com