Method for measuring content of IgG (immunoglobulin G) in pig plasma protein powder

A technology of porcine plasma protein powder and determination method, which is applied in the field of IgG content determination, can solve the problems of affecting the measurement result and incomplete IgG extraction, and achieves the effect of convenient operation, good extraction effect and good linear relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

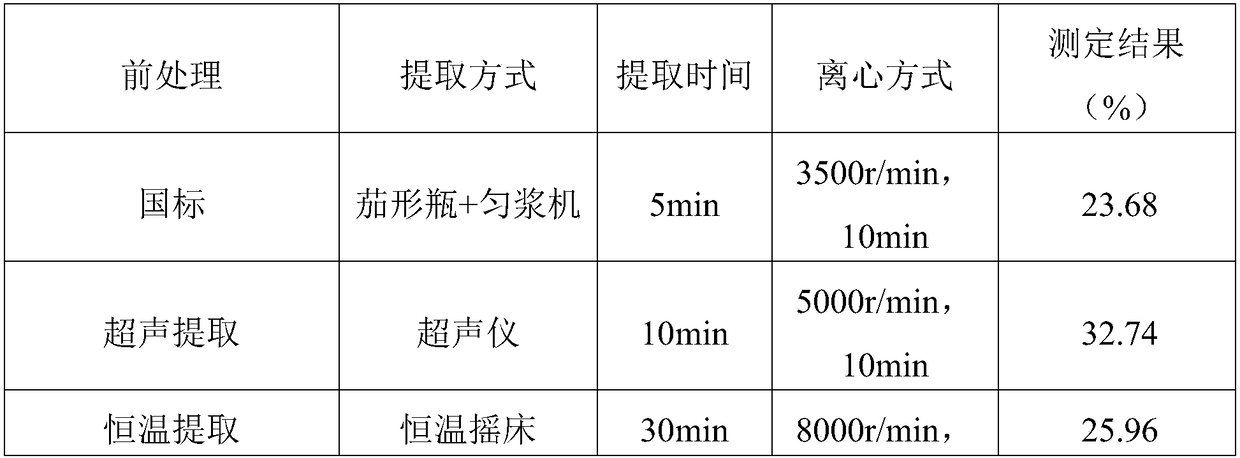

[0027] The determination method of IgG content in pig plasma protein powder is:

[0028] Accurately weigh about 0.1000g of porcine plasma protein powder, and add it to 50mL of potassium phosphate buffer solution with pH=6.5 and 0.05mol / L (i.e., the ratio of solid to liquid is 1:500); Shake at a rotating speed for 30 minutes for constant temperature extraction, then centrifuge at 8000r / min for 10 minutes, and pass through a 0.22 μm filter membrane to obtain the test solution; take 20 μL of the test solution for high performance liquid chromatography detection.

[0029] Wherein, the high performance liquid chromatography conditions are as follows:

[0030] (1) Equipment: Agilent 1260, equipped with a UV detector, the detection wavelength is 280nm;

[0031] (2) Chromatographic column: Pharmacia HI-Trap Protein G column, 1mL;

[0032] (3) Mobile phase A: pH 6.5, 0.05mol / L potassium phosphate buffer (0.05mol / L potassium dihydrogen phosphate and 0.05mol / L dipotassium hydrogen phos...

Embodiment 2

[0043] The determination of IgG content in pig plasma protein powder is as follows:

[0044] 1. Solvents and equipment required for the test

[0045] 1.1HPLC: Aglient 1260, with UV detector;

[0046] 1.2 Chromatographic column: Pharmacia HI-Trap Protein G column, 1mL;

[0047] 1.3Millipore pure water machine;

[0048] 1.4 Analytical balance: accurate to 0.0001g;

[0049] 1.5 Erlenmeyer flask with stopper: 250mL;

[0050] 1.6 Pipette: 50mL pipette, which needs to be calibrated regularly;

[0051] 1.7 Constant temperature shaking incubator: Shanghai Jinghong HZP-150;

[0052] 1.8 high-speed centrifuge: the speed can be adjusted from 0 to 16000r / min;

[0053] 1.9 Mobile phase A: pH 6.5±0.1, 0.05mol / L potassium phosphate buffer (68.5% 0.05mol / L potassium dihydrogen phosphate and 31.5% 0.05mol / L dipotassium hydrogen phosphate are mixed evenly, and fine-tuned with a pH meter);

[0054] 1.10 Mobile phase B: pH 2.5±0.1, 0.05mol / L glycine hydrochloride buffer (250mL 0.2mol / L gly...

Embodiment 3

[0089] A method for assaying IgG content in pig plasma protein powder, comprising the following steps:

[0090] 1) Sampling: Weigh porcine plasma protein powder and add it to potassium phosphate buffer, add 2g of porcine plasma protein powder to every 1000mL potassium phosphate buffer to obtain the sample to be tested, wherein the concentration of potassium phosphate buffer is 0.05mol / L, the pH value is 6.5;

[0091] 2) Constant temperature extraction: place the sample to be tested in a constant temperature shaker at 25°C for 30 minutes at a speed of 150r / min, then centrifuge at 8000r / min for 10 minutes, and then filter the centrifuged sample to be tested with a 0.22μm filter membrane , to obtain the liquid to be tested;

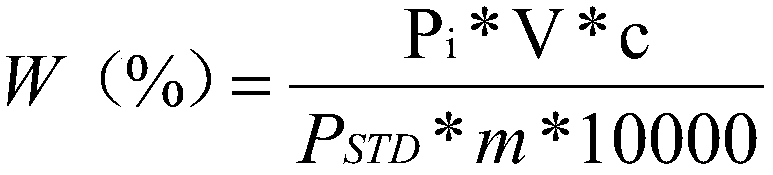

[0092] 3) Get the liquid to be tested and carry out high-performance liquid chromatography detection. During the high-performance liquid chromatography detection process, mobile phase A is a phosphate buffer (pH value is 6.5), and mobile phase B is a glyci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com