Preparation method of pigskin antibacterial polypeptide

The technology of antibacterial polypeptide and antibacterial peptide is applied in the field of preparation of pigskin antibacterial polypeptide, which can solve the problem of little extraction, and achieve the effects of removing fishy smell substances, high yield and purity, and high degreasing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing pigskin antibacterial polypeptides, comprising raw material pretreatment, fermentation medium preparation, Aspergillus niger fermentation, ultrafiltration, and purification, the specific steps of which are:

[0017] 1) Raw material pretreatment: cut fresh pigskin into pieces, add 3% sodium carbonate and 0.031% ethyl valerate aqueous solution at a material-liquid ratio of 1:8 (g / mL), and heat it at a temperature of 45°C and an ultrasonic frequency Degreasing under the condition of 40kHz for 60 minutes, discarding the lye, washing with water until nearly neutral, then adding water to homogenate according to the ratio of material to liquid at 1:8 (g / mL), heating and boiling, filtering, and drying to obtain degreased pork skin. Under the assisted action of ultrasonic waves, the grease can be quickly formed into water-soluble soap salt and glycerin to achieve the purpose of degreasing, and the degreasing rate is high. On the one hand, the addition of et...

Embodiment 2

[0024] A method for preparing pigskin antibacterial polypeptides, comprising raw material pretreatment, fermentation medium preparation, Aspergillus niger fermentation, ultrafiltration, and purification, the specific steps of which are:

[0025] 1) Raw material pretreatment: cut fresh pigskin into pieces, add 2% sodium carbonate and 0.035% ethyl valerate aqueous solution at a material-to-liquid ratio of 1:10 (g / mL), at a temperature of 40°C and an ultrasonic frequency Degrease under the condition of 45kHz for 45min, discard the lye, wash with water until nearly neutral, then add water to homogenate according to the material-liquid ratio of 1:10 (g / mL), heat to boil, filter, and dry to obtain defatted pork skin;

[0026] 2) Fermentation medium preparation: Take 10 parts of defatted pork skin, 20 parts of sucrose, 5 parts of sodium chloride, 0.005 parts of zinc chloride, 2.0 parts of potassium dihydrogen phosphate, 0.4 parts of magnesium sulfate, and 0.01 parts of iron sulfate by...

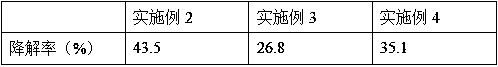

Embodiment 3

[0032] A method for preparing pigskin antibacterial polypeptides, comprising raw material pretreatment, fermentation medium preparation, Aspergillus niger fermentation, ultrafiltration, and purification, the specific steps of which are:

[0033] 1) Raw material pretreatment: cut fresh pigskin into pieces, add 2% sodium carbonate aqueous solution according to the material-liquid ratio of 1:10 (g / mL), and degrease for 45 minutes at a temperature of 40°C and an ultrasonic frequency of 45kHz , discard the lye, wash with water until nearly neutral, then add water to homogenate according to the material-to-liquid ratio of 1:10 (g / mL), heat to boil, filter, and dry to obtain defatted pork skin;

[0034] 2) Fermentation medium preparation: Take 10 parts of defatted pork skin, 20 parts of sucrose, 5 parts of sodium chloride, 0.005 parts of zinc chloride, 2.0 parts of potassium dihydrogen phosphate, 0.4 parts of magnesium sulfate, and 0.01 parts of iron sulfate by weight , Vitamin B 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com