Portable membrane electrode assembly directly generating ozone in water and preparation method of portable membrane electrode assembly

A portable, membrane electrode technology, used in electrodes, chemical instruments and methods, electrolysis processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

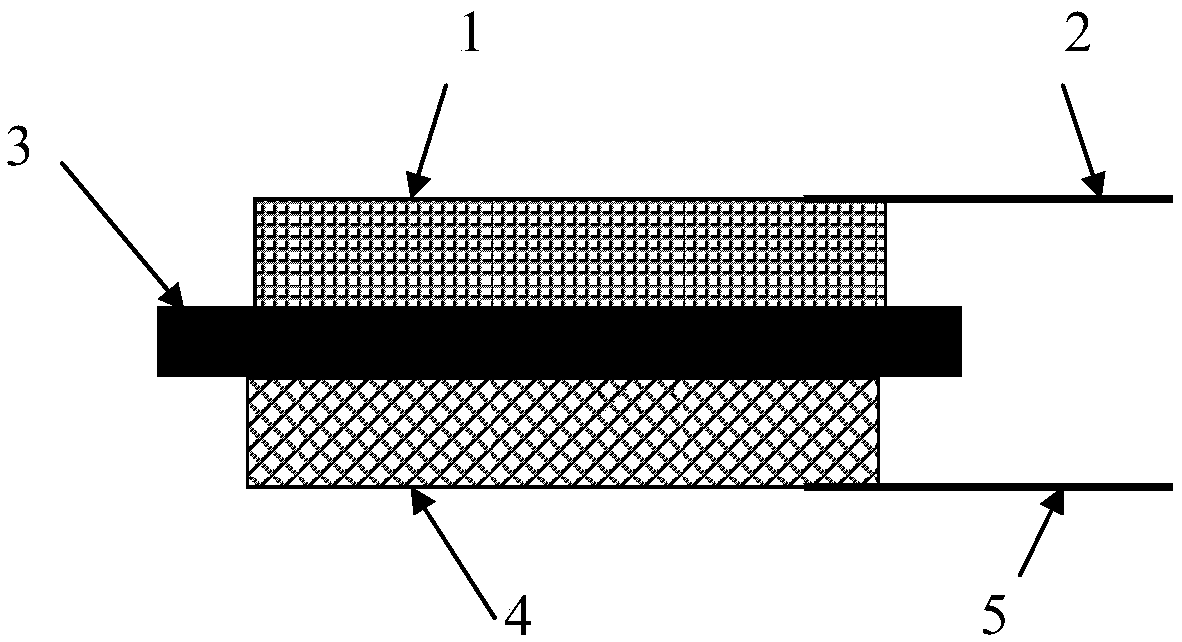

Image

Examples

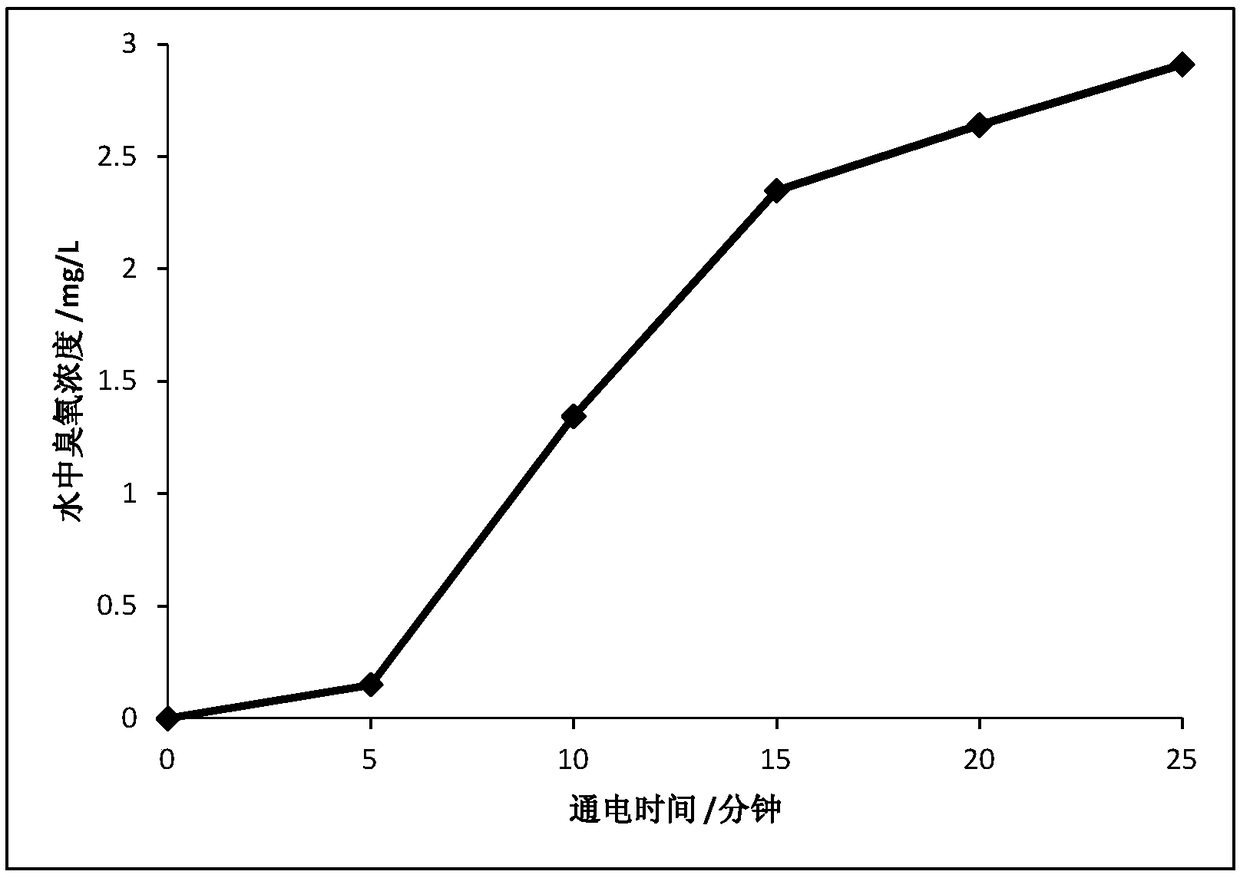

Embodiment 1

[0025] 1) Firstly, the titanium mesh used for the electrode is placed in an oxalic acid solution and boiled for pretreatment to remove impurities on the surface of the titanium substrate;

[0026] 2) Preparation of intermediate layer coating solution:

[0027] According to the atomic ratio of Mn:Sb:Sn=40:20:100, the intermediate layer coating solution is equipped with manganese-containing tin tetrachloride pentahydrate and ethanol of antimony trichloride;

[0028] 3) Preparation of surface active layer coating solution:

[0029] According to the atomic ratio of Ni:Sb:Sn=2:20:1000, the surface active layer coating solution is equipped with nickel-containing tin tetrachloride pentahydrate and ethanol of antimony trichloride;

[0030] 4) Brush the intermediate layer coating solution on the titanium substrate in step 1) or immerse the titanium substrate in the intermediate layer coating solution, then dry the titanium substrate in an oven at 90°C, and then transfer it to a muffle...

Embodiment 2

[0036] 1) First, the titanium plate used for the electrode is placed in a hydrochloric acid solution and boiled for pretreatment to remove impurities on the surface of the titanium substrate;

[0037] 2) Preparation of intermediate layer coating solution:

[0038] According to the atomic ratio of Co:Sb:Sn=10:10:100, the intermediate layer coating solution is equipped with cobalt-containing tin tetrachloride pentahydrate and isopropanol of antimony trichloride;

[0039] 3) Preparation of surface active layer coating solution:

[0040] According to the atomic ratio of Ni:Sb:Sn=8:50:1000, the surface active layer coating solution is equipped with nickel-containing tin tetrachloride pentahydrate and isopropanol of antimony trichloride;

[0041] 4) Brush the intermediate layer coating solution on the titanium substrate in step 1) or immerse the titanium substrate in the intermediate layer coating solution, then dry the titanium substrate in an oven at 70°C, and then transfer it to...

Embodiment 3

[0045] 1) Firstly, the titanium rod used for the electrode is placed in a sulfuric acid solution and boiled for pretreatment to remove impurities on the surface of the titanium substrate;

[0046] 2) Preparation of intermediate layer coating solution:

[0047] According to the atomic ratio of Ru: Sb: Sn = 60: 50: 100, the intermediate layer coating solution is equipped with ruthenium-containing tin tetrachloride pentahydrate and butanol of antimony trichloride;

[0048] 3) Preparation of surface active layer coating solution:

[0049] According to the atomic ratio of Ni:Sb:Sn=5:80:1000, the surface active layer coating solution is equipped with nickel-containing tin tetrachloride pentahydrate and butanol of antimony trichloride;

[0050] 4) Brush the intermediate layer coating solution on the titanium substrate in step 1) or immerse the titanium substrate in the intermediate layer coating solution, then dry the titanium substrate in an oven at 80°C, and then transfer it to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com