Method for prolonging storage time of edible fungus solid spawn

A technology of solid strains and storage time, applied in botany equipment and methods, applications, horticulture, etc., can solve the problems of short storage time, general adaptability, and difficulty in storage, so as to prolong storage time, reduce reproduction speed, The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

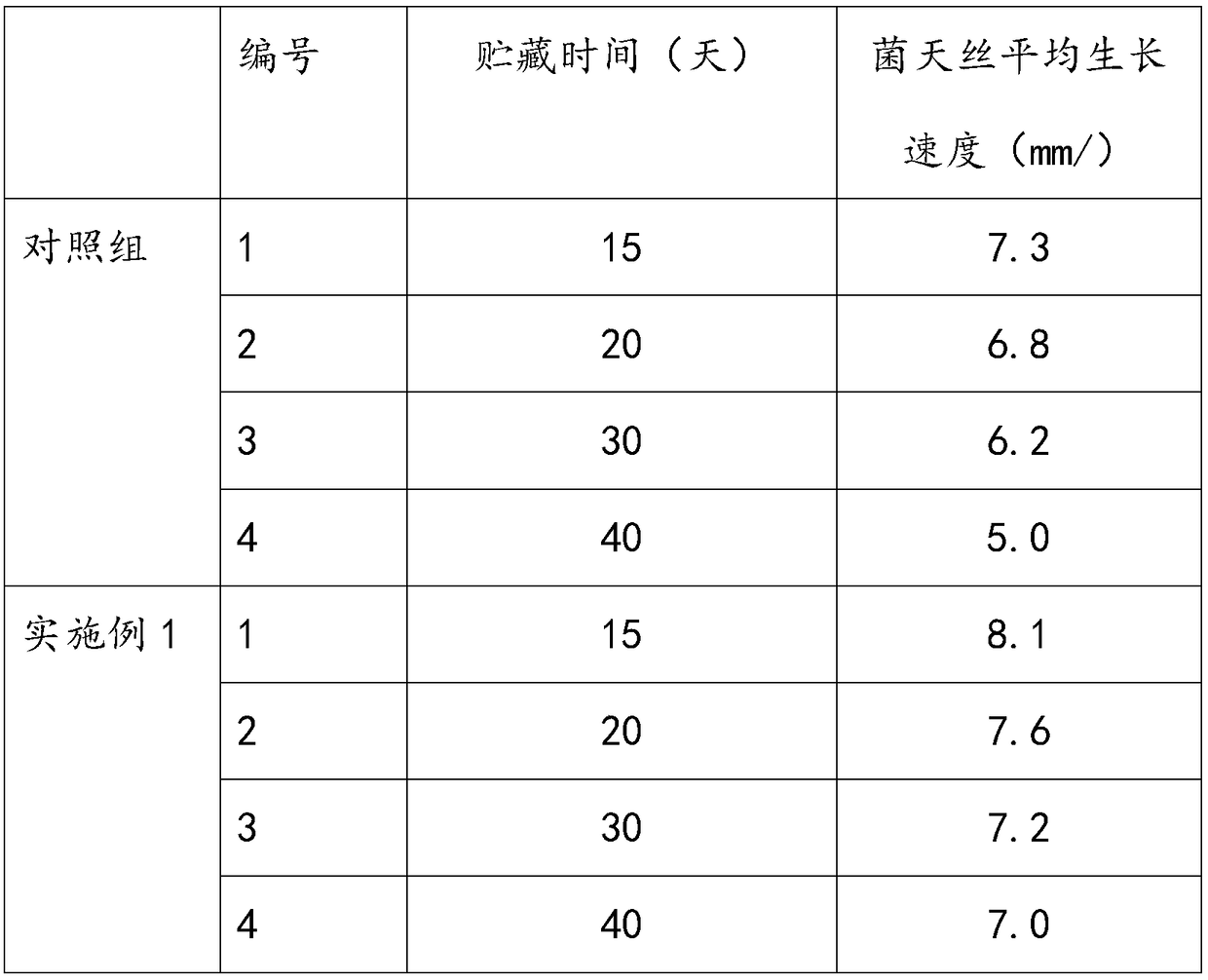

Embodiment 1

[0029] In this embodiment, Pleurotus ostreatus is used for cultivation and a control group is set.

[0030] The solid medium of this embodiment is composed of the following components: trehalose 20g / L, yeast powder 2g / L, peptone 1g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 1.5g / L, agar 15g / L, graphite oxide ene 0.01g / L, N-butylpyridine hexafluorophosphate 0.1g / L, sodium carboxymethylcellulose 0.1g / L, polyacrylamide 0.2g / L, nano calcium carbonate 1.3g / L, lauryl sulfonate 0.2 g / L of sodium bicarbonate, the balance is pure water, and the pH value of the culture medium is adjusted to 5-6.

[0031] Among them, nano-graphene oxide has a purity of ≥99%, a sheet thickness of 0.5-2nm, and a sheet length of 500-900nm.

[0032] The production process of the culture medium includes:

[0033] Step S1, preparation of graphene oxide aqueous solution: disperse graphene oxide, sodium lauryl sulfonate, and N-butylpyridine hexafluorophosphate ultrasonically for 5 minutes accord...

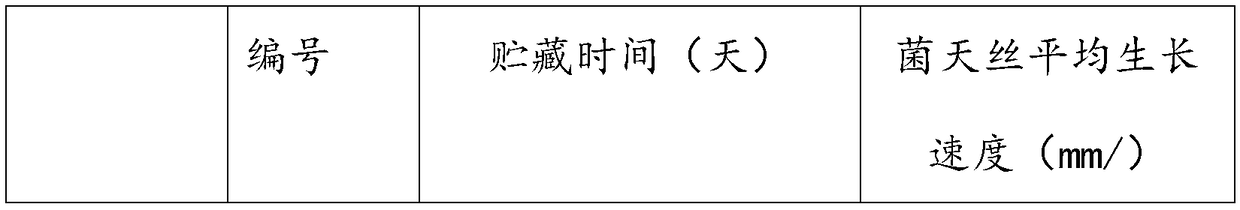

Embodiment 2

[0046] In this embodiment, Pleurotus eryngii is used for cultivation and a control group is set.

[0047] The solid medium in this example consists of the following components: trehalose 25g / L, yeast powder 6g / L, peptone 2g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 2g / L, agar 20g / L, graphene oxide 1.5g / L, N-butylpyridine hexafluorophosphate 0.85g / L, sodium carboxymethylcellulose 0.5g / L, polyacrylamide 0.8g / L, nano calcium carbonate 9.5g / L, lauryl sulfonic acid Sodium is 0.8g / L, the balance is pure water, and the pH value of the medium is adjusted to 5-6.

[0048] Among them, nano-graphene oxide has a purity of ≥99%, a sheet thickness of 0.5-2nm, and a sheet length of 500-900nm.

[0049] The production process of the culture medium includes:

[0050] Step S1, preparation of graphene oxide aqueous solution: disperse graphene oxide, sodium lauryl sulfonate, and N-butylpyridine hexafluorophosphate ultrasonically for 5 minutes according to parts by weight;

[005...

Embodiment 3

[0064] In this embodiment, Flammulina velutipes was used for cultivation and a control group was set.

[0065] The solid medium in this example consists of the following components: trehalose 22g / L, yeast powder 4g / L, peptone 1.5g / L, potassium dihydrogen phosphate 1.5g / L, magnesium sulfate 1.8g / L, agar 18g / L, Graphene oxide 1g / L, N-butyl pyridine hexafluorophosphate 0.5g / L, sodium carboxymethylcellulose 0.3g / L, polyacrylamide 0.5g / L, nano calcium carbonate 5g / L, lauryl sulfonate 0.5g / L of sodium bicarbonate, the balance is pure water, and the pH value of the culture medium is adjusted to 5-6.

[0066] Among them, nano-graphene oxide has a purity of ≥99%, a sheet thickness of 0.5-2nm, and a sheet length of 500-900nm.

[0067] The production process of the culture medium includes:

[0068] Step S1, preparation of graphene oxide aqueous solution: disperse graphene oxide, sodium lauryl sulfonate, and N-butylpyridine hexafluorophosphate ultrasonically for 5 minutes according to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com