Foamed coal ash organic polymer modified heat-preservation material as well as preparation and application thereof

A technology of thermal insulation material and fly ash, which is applied in the field of building thermal insulation materials, can solve the problems of restricting foamed geopolymers, etc., achieve small thermal weight loss, good flexibility and mechanical properties, and improve the effect of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

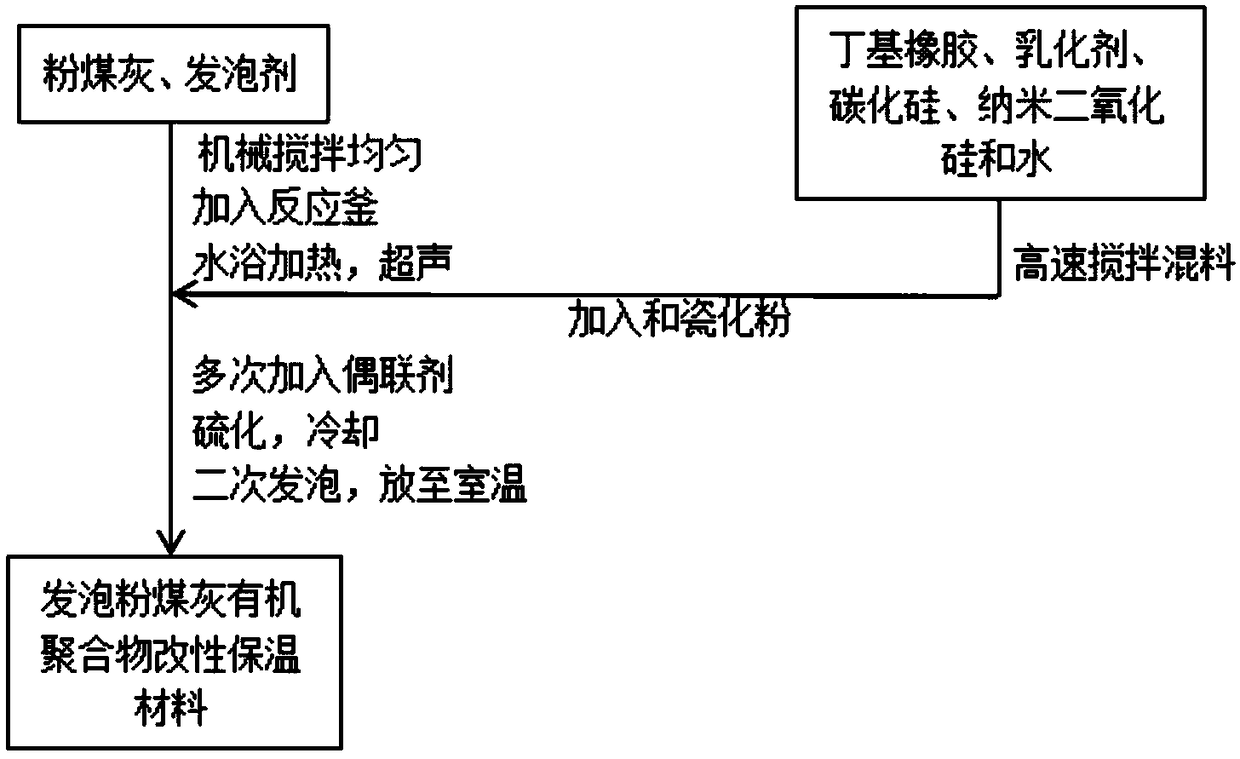

Method used

Image

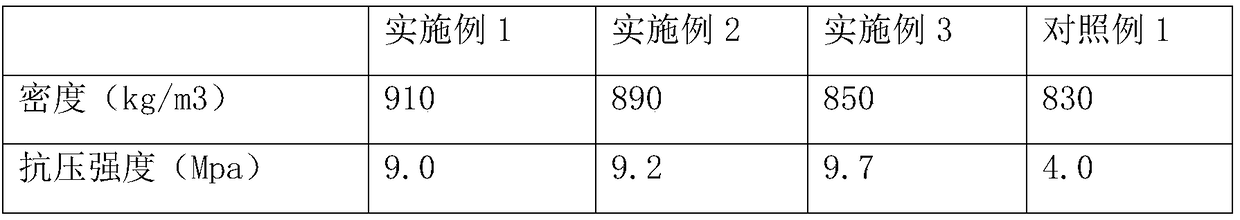

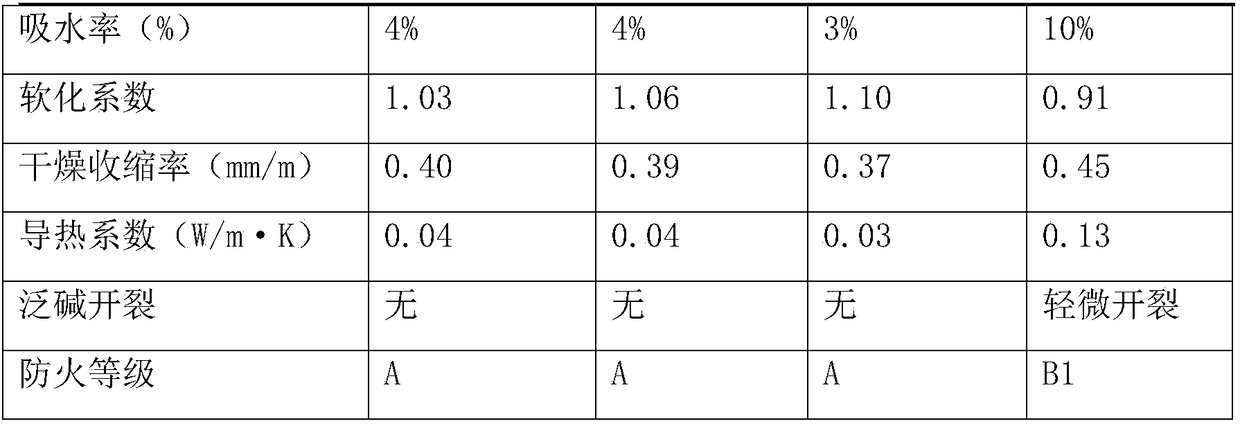

Examples

Embodiment 1

[0024] Example 1 Preparation of foamed fly ash organic polymer modified thermal insulation material

[0025] Raw material composition: 70 parts of fly ash, 40 parts of butyl rubber, 20 parts of silane coupling agent, 2 parts of carbon black, 3 parts of calcium carbonate, 2 parts of low-temperature glass powder, 4 parts of montmorillonite, 4 parts of magnesium oxide, ten 3 parts of hexaalkyltrimethylammonium chloride, 7 parts of fatty alcohol polyoxyethylene ether, 5 parts of silicon carbide and 1 part of nano silicon dioxide;

[0026] Preparation:

[0027] Step 1. Pour butyl rubber, cetyltrimethylammonium chloride, fatty alcohol polyoxyethylene ether, silicon carbide, nano silicon dioxide and water into a high-speed mixer for mixing, discharge at 90°C, and set aside;

[0028] Step 2. Weigh the fly ash in proportion, add silicon carbide and calcium carbonate and pour them into the reaction kettle evenly with mechanical stirring, mechanically stir at 500r / min, ultrasonicate in ...

Embodiment 2

[0030] Example 2 Preparation of foamed fly ash organic polymer modified thermal insulation material

[0031] Raw material composition: 90 parts of fly ash, 60 parts of butyl rubber, 40 parts of silane coupling agent, 15 parts of graphite, 3 parts of aluminum hydroxide, 12 parts of mica powder, 12 parts of kaolin, 6 parts of hexadecyl pyridinium bromide 26 parts, 26 parts of fatty amine polyoxyethylene ether, 15 parts of silicon carbide and 10 parts of nano silicon dioxide;

[0032] Preparation:

[0033] Step 1. Pour butyl rubber, cetyl pyridinium bromide, fatty amine polyoxyethylene ether, silicon carbide, nano silicon dioxide and water into a high-speed mixer for mixing, discharge at 90°C, and set aside;

[0034] Step 2. Weigh the fly ash in proportion, add graphite and stir evenly into the reaction kettle with mechanical stirring, mechanically stir at 500r / min, ultrasonicate in a water bath at 60°C for 30min, add the emulsion prepared in step 1 and aluminum hydroxide, Mica...

Embodiment 3

[0036] Example 3 Preparation of foamed fly ash organic polymer modified thermal insulation material

[0037] Raw material composition: 80 parts of fly ash, 50 parts of butyl rubber, 30 parts of silane coupling agent, 10 parts of water glass, 3 parts of aluminum hydroxide, 9 parts of diatomaceous earth, 10 parts of aluminum oxide, hexadecyl trimethyl 5 parts of ammonium chloride, 15 parts of block polyoxyethylene-polyoxypropylene ether, 10 parts of silicon carbide and 5 parts of nano silicon dioxide;

[0038] Preparation:

[0039] Step 1. Pour butyl rubber, cetyltrimethylammonium chloride, block polyoxyethylene-polyoxypropylene ether, silicon carbide, nano-silica and water into a high-speed mixer for mixing, and leave at 90°C material, spare;

[0040]Step 2. Weigh the fly ash in proportion, add water glass and stir evenly into the reaction kettle with mechanical stirring, mechanically stir at 500r / min, ultrasonicate in a water bath at 60°C for 30min, add the emulsion prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity value | aaaaa | aaaaa |

| Dynamic viscosity value | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com