Preparation method of biological packing for wastewater treatment

A biological filler and wastewater treatment technology, applied in the field of water treatment, can solve the problems of easy to produce balling phenomenon, poor affinity and other problems, and achieve the effect of enhancing water treatment efficiency, preventing agglomeration and enhancing compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

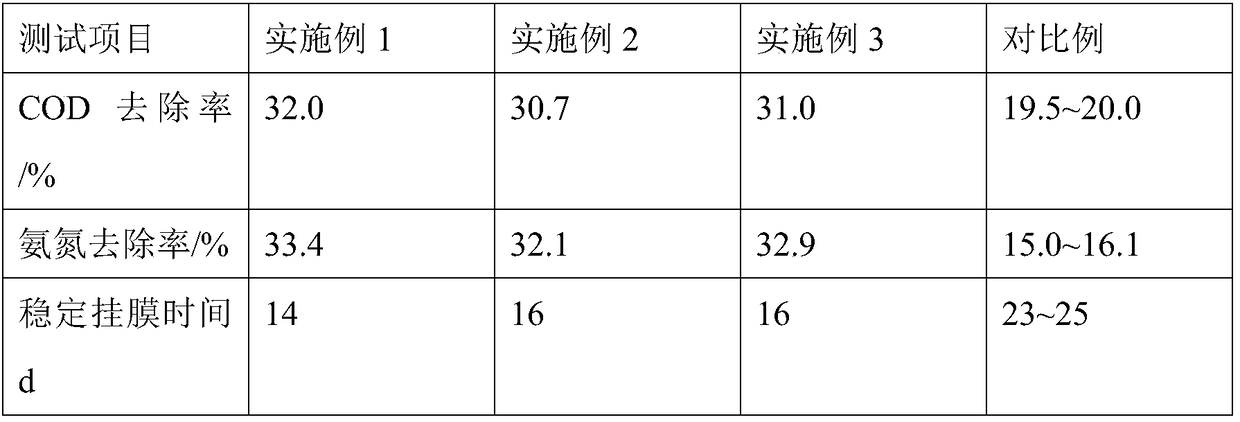

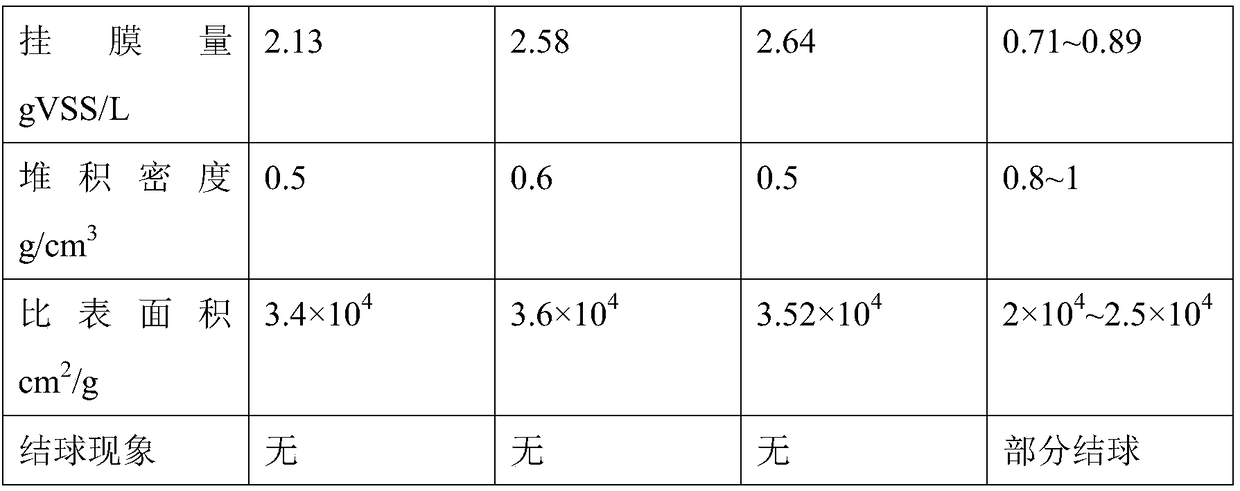

Examples

preparation example Construction

[0025] A preparation method for biological filler for waste water treatment, comprising the steps of:

[0026] (1) Take 10-undecen-1-ol according to the mass ratio of 1~3:9~13, add isopropanol, and pass through nitrogen to obtain a mixture, and take the mixture according to the mass ratio of 8~15:1~3:0.5~ 1.2 Add trimethylaluminum and triisobutylaluminum to mix, stir and mix at -80~-70°C for 1~2h, then keep warm at 25~30°C for 2~3h to obtain mixture A;

[0027] (2) In parts by mass, take 6-10 parts of mixture A, 1-2 parts of methylalumoxane, 0.8-1.2 parts of 2,6-di-tert-butyl-4-methylphenol, 50-60 parts Toluene, nitrogen protection, stirring and mixing for 30 to 40 minutes, then adding propylene with 1 to 3 times the mass of the mixture, raising the temperature to 70 to 80°C and stirring and mixing for 30 to 40 minutes to obtain a stirred mixture;

[0028] (3) Take the stirred mixture and add ferrocene according to the mass ratio of 100-120:1-3, and keep it warm at 5 bar and 70...

Embodiment 1

[0031] Coupling agent: Mix isopropyl triisostearyl titanate, γ-ureidopropyl triethoxysilane, and γ-aminopropyl triethoxysilane at a mass ratio of 1:3:3.

[0032] Microbial growth aid: in parts by mass, take 20 parts of potato starch, 10 parts of agarose, 2 parts of calcium alginate, and 0.1 part of ZnSO 4 ·7H 2 O, 0.02 parts of MnCl 2 4H 2 O, 0.02 parts of H 3 BO 3 , 0.1 part of CoCl 2 ·6H 2 O, 0.01 part of CaCl 2 2H 2 O, 0.01 part of NiCl 2 ·6H 2 O, 0.03 part Na2MoO 4 2H 2 O, 0.1 part of FeCl 2 4H 2 O, 1000 parts of water mixed.

[0033] Dispersing active agent: in parts by mass, 5 parts of white mineral oil, 3 parts of trisodium citrate, 12 parts of liquid paraffin, 2 parts of stearylamide and 5 parts of n-hexanol are mixed to obtain the product.

[0034] Adjuvant: Mix sodium hydroxide and sodium gluconate in a mass ratio of 1:1:15.

[0035] A preparation method for biological filler for waste water treatment, comprising the steps of:

[0036] (1) Take 10-un...

Embodiment 2

[0041] Coupling agent: Mix isopropyl triisostearyl titanate, γ-ureidopropyl triethoxysilane, and γ-aminopropyl triethoxysilane at a mass ratio of 2:5:5.

[0042] Microbial growth aid: in parts by mass, take 25 parts of potato starch, 13 parts of agarose, 3 parts of calcium alginate, and 0.3 parts of ZnSO 4 ·7H 2 O, 0.03 parts of MnCl 2 4H 2 O, 0.03 parts of H 3 BO 3 , 0.2 parts of CoCl 2 ·6H 2 O, 0.02 parts of CaCl 2 2H 2 O, 0.03 parts of NiCl 2 ·6H 2 O, 0.04 parts of Na2MoO 4 2H 2 O, 0.3 parts of FeCl 2 4H 2 O, 1000 parts of water mixed.

[0043] Dispersing active agent: in parts by mass, 7 parts of white mineral oil, 4 parts of trisodium citrate, 13 parts of liquid paraffin, 3 parts of stearylamide and 7 parts of n-hexanol are mixed to obtain the product.

[0044] Adjuvant: Mix sodium hydroxide and sodium gluconate in a mass ratio of 1:2:17.

[0045] A preparation method for biological filler for waste water treatment, comprising the steps of:

[0046] (1) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com