Bipolar membrane using zinc-metal organic framework material as middle interface layer and preparation method thereof

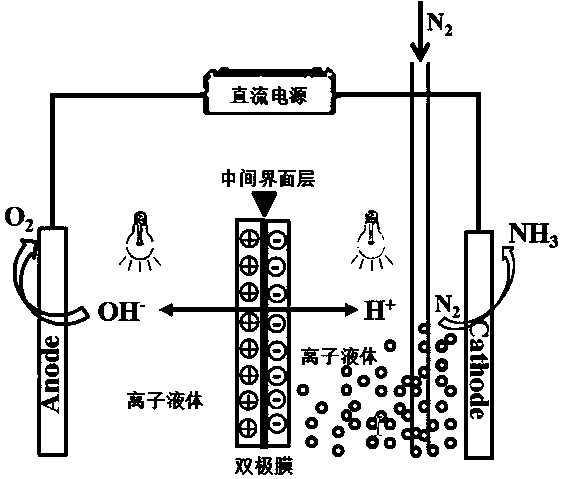

A metal-organic framework and interfacial layer technology, applied in the direction of organic membranes, electrodes, cells, etc., can solve the problems of low nitrogen reduction efficiency, reduced catalytic activity of cathode materials, and reduced reduction rate, so as to improve photoelectric conversion efficiency and achieve sustainable Operation and promotion of water dissociation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Zn-MOF:

[0030] Dissolve the dried zinc nitrate and terephthalic acid in N,N-dimethylformamide at a molar ratio of 4:3, add the ionic liquid of 1-butyl-3-methylimidazolium chloride salt, and stir until completely After dissolving, it is used as an electrolyte; a zinc sheet is inserted as an anode, and a titanium sheet is used as a cathode, at a current density of 0.025A cm -2 After 2.5 h of reaction, a white flocculent precipitate precipitated out of the solution, which was filtered, washed three times with N,N-dimethylformamide and chloroform, and then dried and stored. The morphology and structure are shown in the appendix figure 1 .

[0031] Preparation of bipolar membrane:

[0032] The preparation mass fraction is 2.5% carboxymethyl cellulose aqueous solution, and the polyvinyl alcohol aqueous solution of 2.5%, after mixing and constantly stirring to form a jelly, make the cation exchange membrane liquid after standing defoaming 90 minutes, the cat...

Embodiment 2

[0037] Preparation of Zn-MOF:

[0038] Dissolve the dried zinc nitrate and terephthalic acid in N,N-dimethylformamide at a molar ratio of 4:3, add the ionic liquid of 1-butyl-3-methylimidazolium bromide, and stir until completely Dissolved as electrolyte; insert zinc foil as anode, copper as cathode, at a current density of 0.035A cm -2 After reacting for 1.5 h, a white flocculent precipitate precipitated out of the solution. The precipitate was filtered, washed three times with N,N-dimethylformamide and chloroform, and then dried and stored. The morphology and structure are shown in the appendix figure 2 .

[0039] Preparation of bipolar membrane:

[0040] Preparation mass fraction is 1.5% cellulose acetate aqueous solution, and 1.5% polyvinylpyrrolidone aqueous solution, mixes and constantly stirs to form jelly, makes cation-exchange membrane liquid after standing defoaming for 60 minutes, and cation-exchange membrane liquid Cast on a clean glass plate with a frame, and ...

Embodiment 3

[0045] Preparation of Zn-MOF:

[0046] Dissolve the dried zinc nitrate and terephthalic acid in N,N-dimethylformamide at a molar ratio of 4:3, add the ionic liquid of 1-butyl-3-methylimidazolium chloride salt, and stir until completely After dissolving, it is used as an electrolyte; a zinc sheet is inserted as an anode, and a titanium sheet is used as a cathode, at a current density of 0.015A cm -2 After 3.5 h of reaction, a white flocculent precipitate precipitated out of the solution, which was filtered, washed three times with N,N-dimethylformamide and chloroform, and then dried and stored.

[0047] Preparation of bipolar membrane:

[0048] Preparation mass fraction is the cellulose acetate aqueous solution of 3.5%, and the polyvinyl alcohol aqueous solution of 3.5%, after mixing and constantly stirring to form jelly, after leaving standstill defoaming 80 minutes, make cation-exchange membrane liquid, the cation-exchange membrane liquid Cast on a clean glass plate with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com