Preparation method and application of 3D ordered titanium dioxide inverse opal photonic crystal microsphere

A photonic crystal microsphere, titanium dioxide technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of photonic crystal film shedding, difficult to prepare large area, limit sunlight utilization, etc. order, many surface active sites, and the preparation method is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of monodisperse polystyrene-methyl methacrylate-acrylic acid P(St-MMA-AA) pellets: Dissolve 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 2ml acrylic acid monomer in 10ml deionized In water, record it as solution A; take 250ml deionized water, 11ml styrene and 1ml methyl methacrylate monomer and add them into a three-necked flask to mix and stir, pass N 2 Protection, when the temperature of the liquid in the bottle rises to 70°C, quickly add solution A to the mixed liquid in the bottle; keep stirring at 70°C for 12 hours to obtain a uniform emulsion of 330nm;

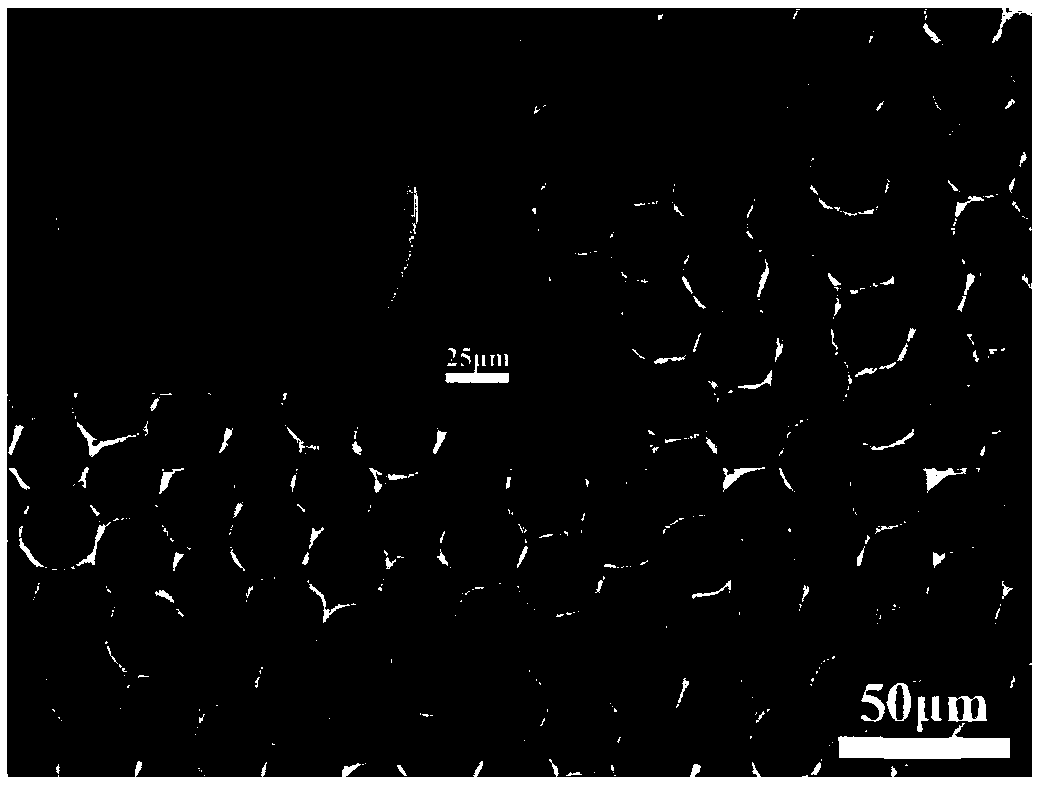

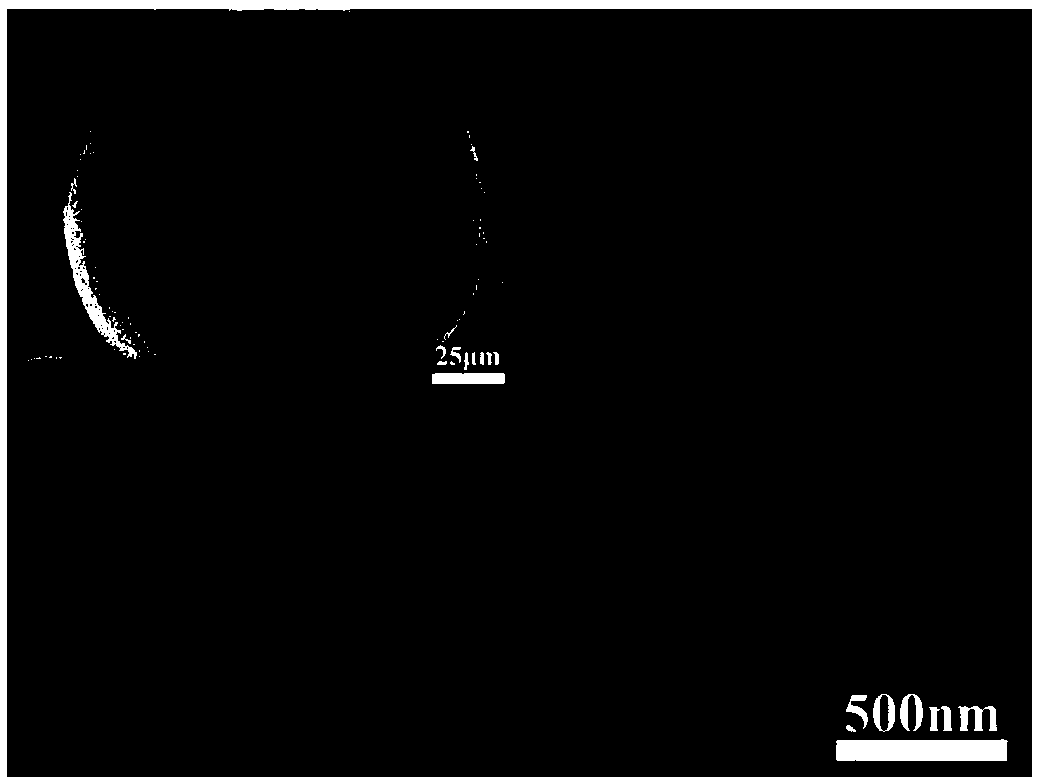

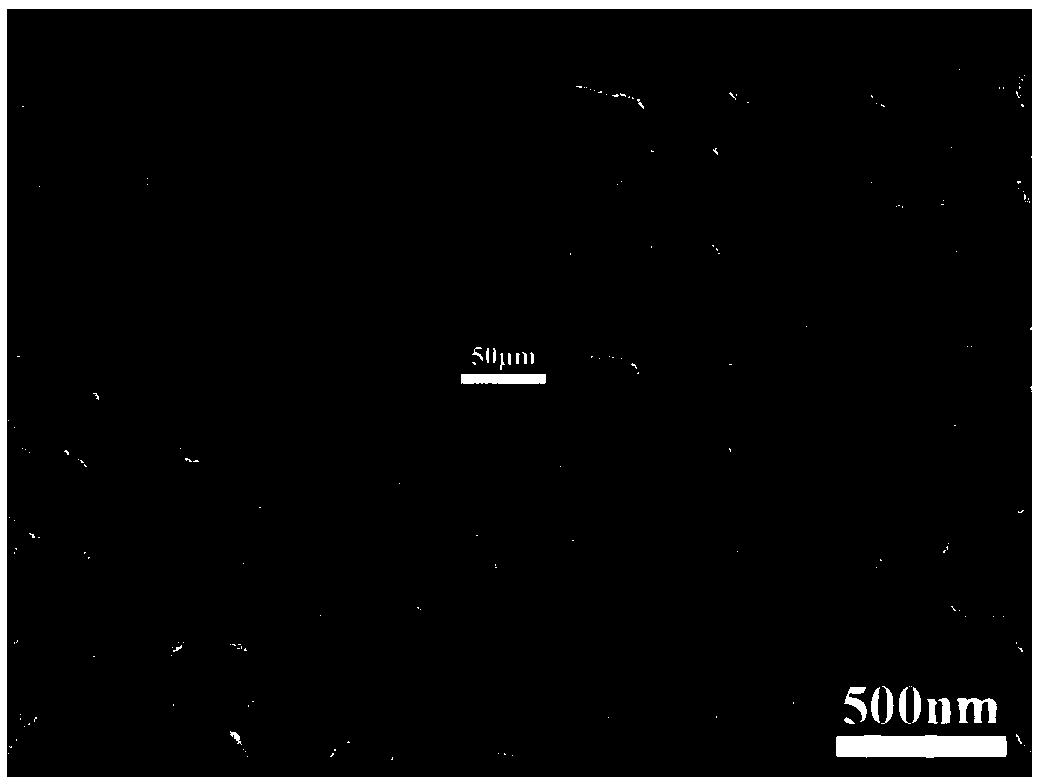

[0029] (2) Preparation of three-dimensional ordered titanium dioxide inverse opal photonic crystal microspheres: Mix 0.85ml of P(St-MMA-AA) solution with a mass fraction of 15% and 100μl of titanium precursor solution, and inhale the solution evenly after ultrasonic dispersion 1ml syringe; at the same time, use a 10ml syringe to absorb 10ml of low-viscosity methyl silicone oil; connect t...

Embodiment 2

[0031] (1) Preparation of monodisperse polystyrene-methyl methacrylate-acrylic acid P(St-MMA-AA) pellets: Dissolve 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 2ml acrylic acid monomer in 10ml deionized In water, record it as solution A; take 250ml deionized water, 12ml styrene and 1ml methyl methacrylate monomer and add them into a three-necked flask for mixing and stirring, and pass through N 2 Protection, when the temperature of the liquid in the bottle rises to 70°C, quickly add solution A to the mixed liquid in the bottle; keep stirring at 70°C for 12 hours to obtain a uniform emulsion of 360nm;

[0032] (2) Preparation of three-dimensional ordered titanium dioxide inverse opal photonic crystal microspheres: mix 0.96ml of P(St-MMA-AA) solution with a mass fraction of 15% and 100μl of titanium precursor solution, and inhale the solution evenly after ultrasonic dispersion 1ml syringe; at the same time, use a 10ml syringe to absorb 10ml of low-viscosity methyl sil...

Embodiment 3

[0034] (1) Preparation of monodisperse polystyrene-methyl methacrylate-acrylic acid P(St-MMA-AA) pellets: Dissolve 0.4g ammonium persulfate, 0.8g ammonium bicarbonate and 2ml acrylic acid monomer in 10ml deionized In water, record as solution A; take 250ml of deionized water, 13ml of styrene and 1ml of methyl methacrylate monomer into a three-necked flask for mixing and stirring, and pass N 2 Protection, when the temperature of the liquid in the bottle rises to 70°C, quickly add solution A to the mixed liquid in the bottle; keep stirring at 70°C for 12 hours to obtain a uniform emulsion of 410nm;

[0035](2) Preparation of three-dimensional ordered titanium dioxide inverse opal photonic crystal microspheres: mix 1.01ml of P(St-MMA-AA) solution with a mass fraction of 15% and 100μl of titanium precursor solution, and inhale the solution after ultrasonic dispersion 1ml syringe; at the same time, use a 10ml syringe to draw 10ml of low-viscosity methyl silicone oil; connect the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com