A kind of magnetic lithium metal battery copper magnetic composite electrode material and its preparation process and application

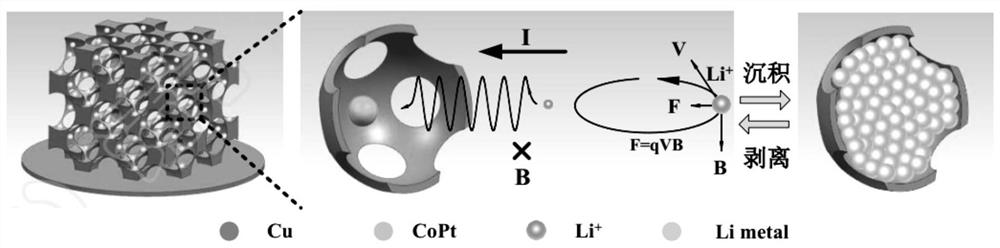

A lithium metal battery and preparation technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of promoting nucleation, reducing local current density, and enhancing mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

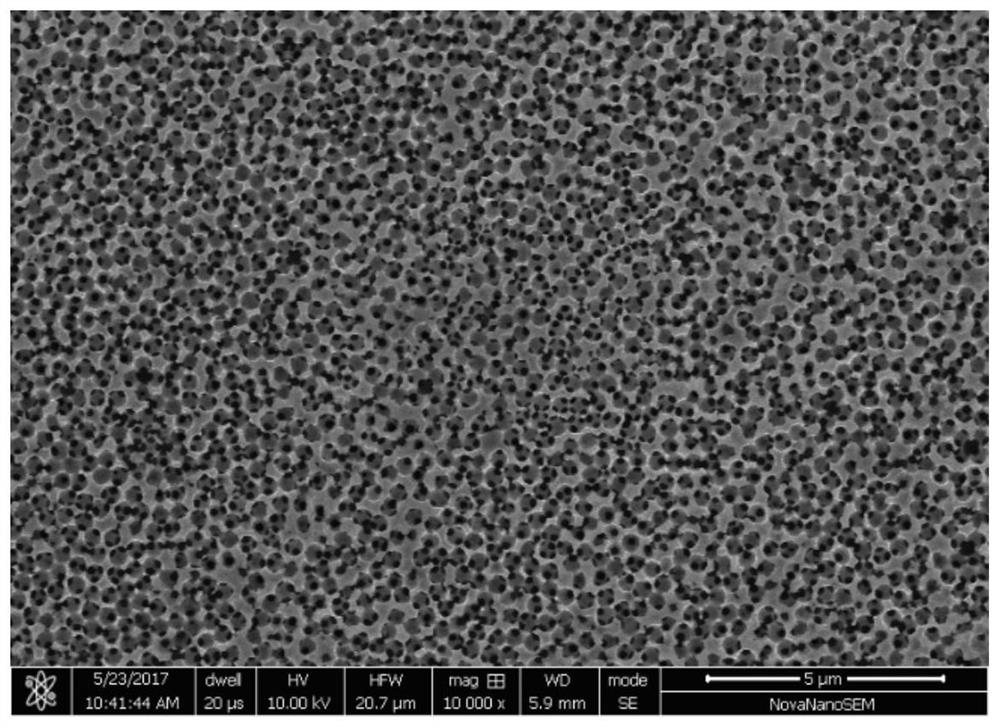

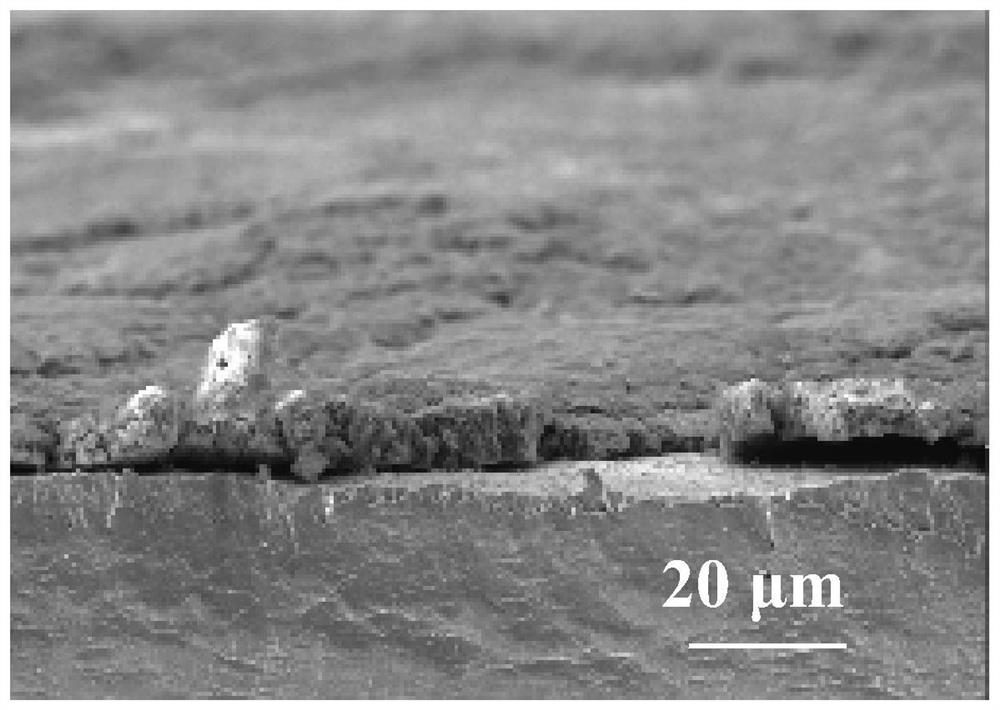

[0063] Mix polymethyl methacrylate microspheres and water at a mass ratio of 50:250, stir to form an emulsion for use; prepare the prepared emulsion, water and polyethylene glycol at a volume ratio of 20:400:2 Proportional mixing, ultrasonic dispersion or stirring to obtain the electrodeposition solution; use the bare copper substrate as the working electrode, platinum as the counter electrode, and use the above electrodeposition solution as a solution system for electrodeposition, control the electrodeposition voltage to 4V, and the current to 0.006A , the deposition time was 45s, and a bare copper substrate covered with a polymethyl methacrylate microsphere stencil was obtained. Mix water and diammonium hydrogen citrate at a mass ratio of 100:2, stir to form a uniform mixed solution, add soluble copper salt copper pyrophosphate and sodium pyrophosphate to the mixed solution and stir to prepare a copper-containing electrodeposition solution, wherein : The concentration of cop...

Embodiment 2

[0065] Mix starch microspheres, chitosan microspheres and water at a mass ratio of 50:250, stir to form an emulsion for later use; prepare the prepared emulsion, water and polyethylene glycol at a volume ratio of 10:300:1 The ratio of mixing, ultrasonic dispersion or stirring to obtain the electrodeposition solution; use the copper substrate as the working electrode, platinum as the counter electrode, and the above electrodeposition solution as a solution system for electrodeposition, control the electrodeposition voltage to 1.0V, and the current to be 0.001A, the deposition time is 10s, and the bare copper substrate covered with starch microspheres and chitosan microsphere templates is obtained. Mix water and potassium hydrogen phthalate at a mass ratio of 100:1, stir to form a uniform mixed solution, add soluble copper salt copper pyrophosphate and sodium pyrophosphate to the mixed solution and stir to prepare a copper-containing electrodeposition solution, Wherein: the copp...

Embodiment 3

[0067]Mix albumin microspheres, polystyrene microspheres and polyacrylic acid microspheres with water at a mass ratio of 100:350, stir to form an emulsion for later use; prepare the prepared emulsion, water and polyethylene glycol by volume Mix at a ratio of 30:700:3, ultrasonically disperse or stir to obtain an electrodeposition solution; use the bare copper substrate as a working electrode, use platinum as a counter electrode, and use the above electrodeposition solution as a solution system for electrodeposition to control the electrodeposition voltage The current is 7.0V, the current is 0.02A, and the deposition time is 90s to obtain a bare copper substrate covered with albumin microspheres, polystyrene microspheres and polyacrylic acid microsphere templates. Mix water and diammonium hydrogen citrate at a mass ratio of 100:5, stir to form a uniform mixed solution, add soluble copper salt copper pyrophosphate and sodium pyrophosphate to the mixed solution and stir to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com