Preparation method and product of ferromagnetic nanowire

A ferromagnetic nanowire and ferromagnetic technology, applied in the field of preparation of ferromagnetic nanowires, can solve the problems of limited aspect ratio of iron nanowires and slow dropping process, and achieve good orientation, controllable process and synthetic route. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

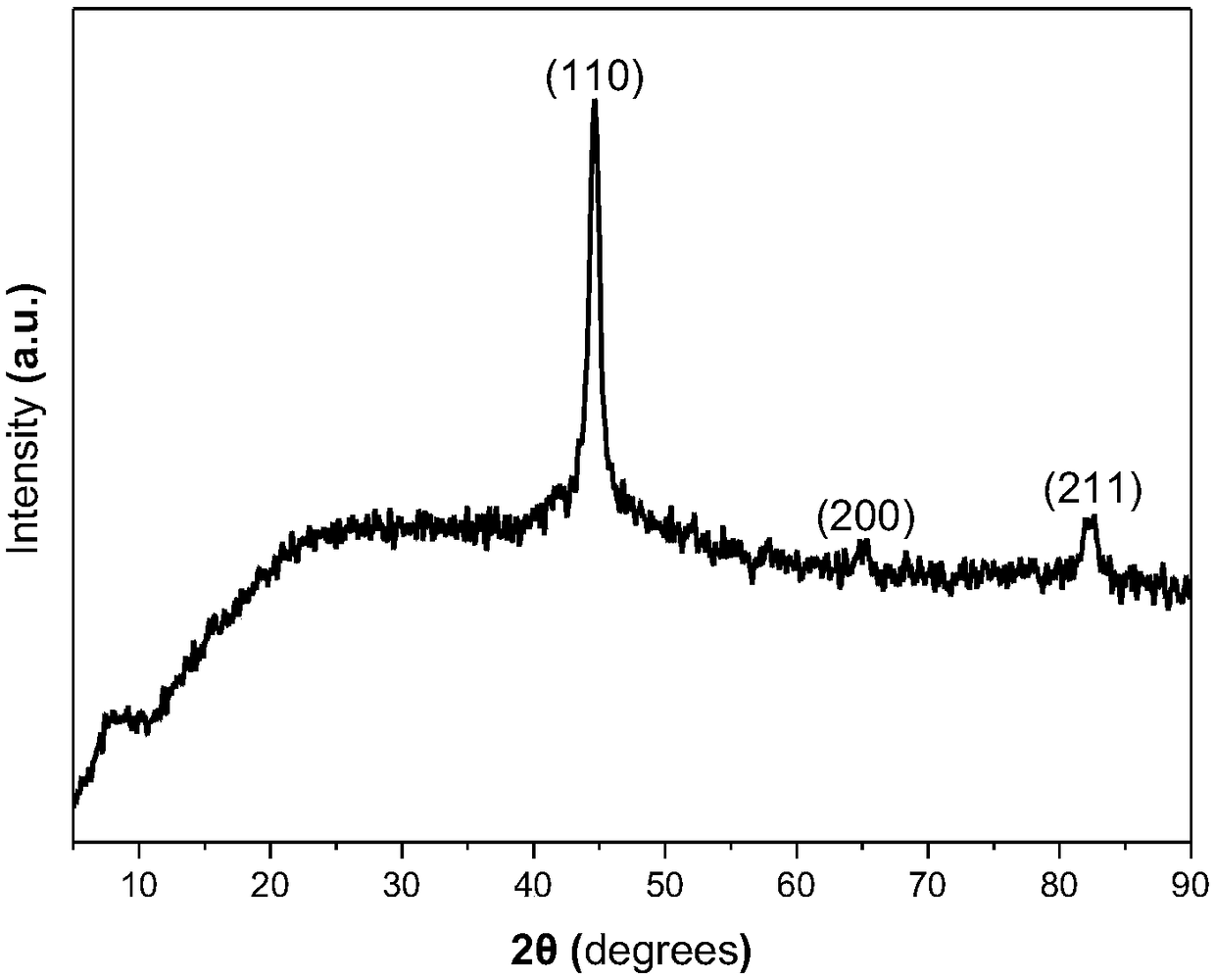

[0031] Preparation of Ferromagnetic Nanowires

[0032] 1. A method for preparing ferromagnetic nanowires, said method comprising the steps of:

[0033] (1) Dissolve ferromagnetic metal salt (ferrous sulfate heptahydrate) in deionized water, then adjust the pH value to 11 with a pH regulator (sodium hydroxide), then add stabilizer (gelatin), complexing agent (polymer Vinylpyrrolidone) and surfactant (polyethylene glycol), after stirring, feed nitrogen to remove the oxygen in the solution, form ferrous sulfate heptahydrate mixed solution; Ferrous sulfate heptahydrate in this ferrous sulfate heptahydrate mixed solution The concentration is 0.05mol / L, the gelatin concentration is 0.02mol / L, the polyvinylpyrrolidone concentration is 0.0015mol / L, and the polyethylene glycol concentration is 0.0025mol / L;

[0034](2) After the reducing agent (sodium borohydride) is dissolved in deionized water, a sodium borohydride solution is formed; the concentration of sodium borohydride in the so...

Embodiment 2

[0037] 1. A method for preparing ferromagnetic nanowires, said method comprising the steps of:

[0038] (1) Dissolve the ferromagnetic metal salt (ferric chloride) in deionized water, then adjust the pH value to 12 with a pH regulator (sodium bicarbonate), then add a stabilizer (dodecyl acetic acid), complex Mixture (glycerin) and surfactant (polystyrene), after stirring, feed nitrogen to remove the oxygen in the solution, form ferric chloride mixed solution; Ferric chloride concentration in this ferric chloride mixed solution is 0.08mol / L, the concentration of lauryl acetate is 0.04mol / L, the concentration of glycerol is 0.001mol / L, and the concentration of polystyrene is 0.002mol / L;

[0039] (2) After the reducing agent (potassium borohydride) is dissolved in absolute ethanol, a potassium borohydride solution is formed; the concentration of potassium borohydride in the potassium borohydride solution is 0.9mol / L;

[0040] (3) The potassium borohydride solution formed in the...

Embodiment 3

[0042] 1. A method for preparing ferromagnetic nanowires, said method comprising the steps of:

[0043] (1) Dissolve the ferromagnetic metal salt (ferric citrate) in deionized water, then adjust the pH value to 10 with a pH regulator (sodium carbonate), then add a stabilizer (dimethyl dithiocarbamate), Complexing agent (sodium nitrilotriacetate) and surfactant (sodium dodecylbenzenesulfonate), after stirring, feed nitrogen to remove oxygen in the solution to form a ferric citrate mixed solution; the ferric citrate mixed solution The concentration of ferric citrate in the medium is 0.15mol / L, the concentration of dimethyl dithiocarbamate is 0.02mol / L, the concentration of sodium nitrilotriacetate is 0.002mol / L, and the concentration of sodium dodecylbenzenesulfonate is 0.003mol / L;

[0044] (2) After dissolving the reducing agent (hydrazine hydrate) in an aqueous solution of ethanol formed by mixing absolute ethanol and deionized water at a volume ratio of 1:1, a hydrazine hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com