A copper-based catalyst for the synthesis of vinyl chloride by acetylene hydrochlorination and its preparation method and application

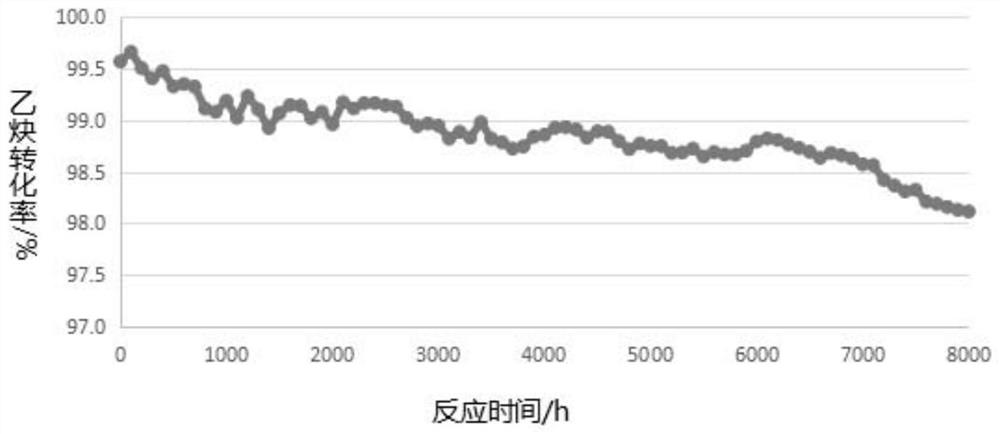

A technology for the synthesis of vinyl chloride and copper-based catalysts by hydrochlorination of acetylene, which is applied in the direction of hydrogen halide addition preparation, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Problems such as poor stability and easy loss of active components of the catalyst can achieve the effects of reducing hazardous waste emissions, reducing waste acid, and improving catalytic activity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

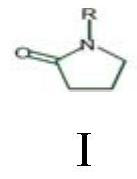

[0050] (1) Weigh 68.6g CuCl 2 2H 2 O and 18.6g R is CH 2 CH 2 OH (oxygen-containing polar groups are alcohol groups), dissolved in 67.5g deionized water, to obtain an impregnation solution containing copper chloride and pyrrolidone compounds;

[0051] (2) The specific surface area is 700 ~ 1500m 2 / g, the carbon tetrachloride adsorption value is 50~70%, the ash value is less than 6%. The granular activated carbon after pickling is soaked in the above-mentioned prepared solution at room temperature, and the control soaking temperature is room temperature, the volume of solution and activated carbon The ratio is 1.5:1, soak until the concentration of copper chloride in the solution is constant;

[0052] (3) Filter the soaked activated carbon, dry it, and dry it at 120°C to obtain the required catalyst A1;

[0053] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1.05) into the tube reactor equipped with catalyst A1 for hydrochlorination ...

Embodiment 2

[0055] (1) Weigh 152.2g CuCl 2 2H 2 O and 40g R is CH 2 COCH 3 (The oxygen-containing polar group is a ketone group), dissolved in 207.8g of deionized water, to obtain an impregnation solution containing copper chloride and pyrrolidone compound;

[0056] (2) The specific surface area is 700 ~ 1500m 2 / g, the carbon tetrachloride adsorption value is 50~70%, and the granular activated carbon after the ash content is less than 6% is soaked in the above-mentioned prepared solution at room temperature, and the control soaking temperature is 70 ℃, the solution and activated carbon The volume ratio is 2:1, soak until the concentration of copper chloride in the solution is constant;

[0057] (3) Filter the soaked activated carbon, dry it, and dry it at 120°C to obtain the required catalyst A2;

[0058] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1) into the tube reactor equipped with catalyst A2 for hydrochlorination reaction, the reactio...

Embodiment 3

[0060] (1) Weigh 101.5g CuCl 2 2H 2 O and 4g R is CH 2 CH 2 OCOCH 3 (The oxygen-containing polar group is an ester group), dissolved in 94.5g deionized water, to obtain an impregnation solution containing copper chloride and pyrrolidone compound;

[0061] (2) The specific surface area is 700 ~ 1500m 2 / g, the adsorption value of carbon tetrachloride is 50-70%, and the ash value is less than 6%. The granular activated carbon after pickling is soaked in the above-mentioned prepared solution at room temperature, and the soaking temperature is controlled to be 50°C. The volume ratio is 1:1, soak until the concentration of copper chloride in the solution is constant;

[0062] (3) filter the soaked activated carbon, dry it, and dry it at 150°C to obtain the required catalyst A3;

[0063] (4) put C 2 h 2 Mixed gas with HCl (C 2 h 2 The molar ratio of HCl and HCl is 1:1) into the tube reactor equipped with catalyst A3 for hydrochlorination reaction, the reaction temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com