Antibacterial sound insulation board and preparation method thereof

A plate and ceramic foam technology, applied in the field of materials, can solve the problems of not being able to effectively absorb high, medium and low frequency sound waves at the same time, high energy consumption of materials, environmental protection, poor impact resistance, etc., to achieve good adhesion, low cost, and improved The effect of tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

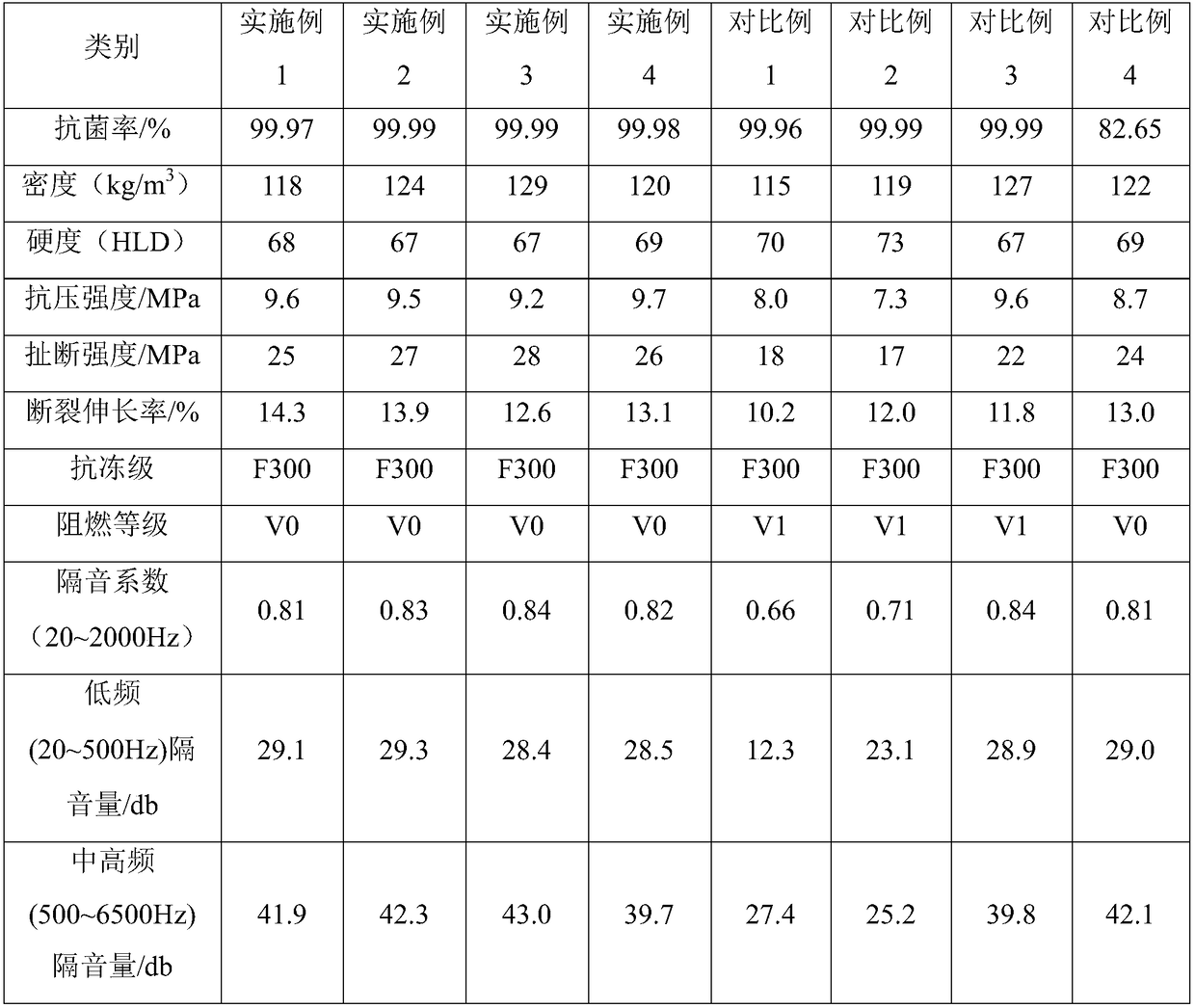

Examples

Embodiment 1

[0030] An antibacterial and sound-insulating board, made of the following components in parts by weight: 5 parts of nano-titanium dioxide, 5 parts of nano-silver particles, 40 parts of high-damping silicone rubber, 40 parts of EPDM rubber, 15 parts of basalt fiber, and benzene peroxide 1 part of formyl, 80 parts of EVA resin, 20 parts of white carbon black, 4 parts of hydroxyl silicone oil, 23 parts of foam ceramic powder, 2 parts of mica powder, 0.3 parts of zinc oxide, 2 parts of stearic acid, 1.2 parts of accelerator, anti-aging agent 2 parts, 5 parts of bamboo charcoal particles, 3 parts of zinc borate, 5 parts of high vinyl silicone oil, 0.2 parts of silane coupling agent.

[0031] A preparation method for an antibacterial sound-insulating board, comprising the following steps:

[0032] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0033]Step 2. Melting: Add EVA resin pellets into the kneader to melt and plasticize, slowly add nano-titanium...

Embodiment 2

[0042] An antibacterial and sound-insulating board, made of the following components in parts by weight: 6 parts of nano-titanium dioxide, 5.2 parts of nano-silver particles, 50 parts of high-damping silicone rubber, 42 parts of EPDM rubber, 18 parts of basalt fiber, and benzene peroxide 1.5 parts of formyl, 85 parts of EVA resin, 24 parts of white carbon black, 4.5 parts of hydroxyl silicone oil, 25 parts of ceramic foam powder, 2.5 parts of mica powder, 0.35 parts of zinc oxide, 2.5 parts of stearic acid, 1.4 parts of accelerator, anti-aging agent 2.2 parts, 6 parts of bamboo charcoal particles, 4 parts of zinc borate, 6 parts of high vinyl silicone oil, 0.25 parts of silane coupling agent.

[0043] A preparation method for an antibacterial sound-insulating board, comprising the following steps:

[0044] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0045] Step 2. Melting: Add EVA resin pellets into the kneader to melt and plasticize, slowly a...

Embodiment 3

[0054] An antibacterial and sound-insulating board, made of the following components in parts by weight: 9 parts of nano-titanium dioxide, 5.8 parts of nano-silver particles, 65 parts of high-damping silicone rubber, 46 parts of EPDM rubber, 26 parts of basalt fiber, and benzene peroxide 1.8 parts of formyl, 90 parts of EVA resin, 28 parts of white carbon black, 5.5 parts of hydroxyl silicone oil, 35 parts of ceramic foam powder, 3.5 parts of mica powder, 0.45 parts of zinc oxide, 3.5 parts of stearic acid, 1.6 parts of accelerator, anti-aging agent 2.8 parts, 8 parts of bamboo charcoal particles, 6 parts of zinc borate, 7 parts of high vinyl silicone oil, 0.35 parts of silane coupling agent.

[0055] A preparation method for an antibacterial sound-insulating board, comprising the following steps:

[0056] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0057] Step 2. Melting: Add EVA resin pellets into the kneader to melt and plasticize, slowly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com