A kind of piezo-capacitance bifunctional titania ceramic with high dielectric constant and preparation method thereof

A high dielectric constant, titanium dioxide technology, applied in the direction of varistor, varistor core, etc., can solve the problems of high potential gradient, nonlinear coefficient and low dielectric constant value, etc., to achieve strong repeatability, preparation The effect of simple process and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

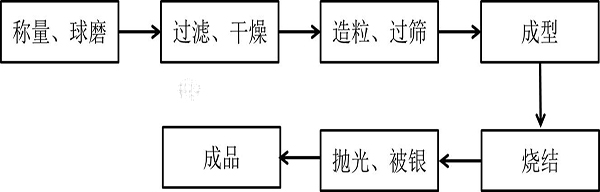

Method used

Image

Examples

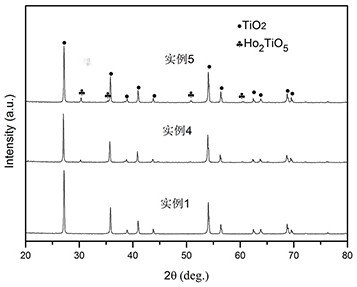

Embodiment 1

[0027] Micron-sized powder according to 99.35mol%TiO 2 , 0.3mol%SiO 2 , 0.2mol%Nb 2 o 5 , 0.15mol%Ho 2 o 3 Weigh the mixture and place it in an agate jar, add an appropriate amount of ethanol, and mill it on a planetary ball mill for 10 hours at a speed of 300r / min to make the powder evenly mixed. Filter the ball-milled slurry and put it in a drying oven at 60°C for 24 hours. Add 5wt% polyvinyl alcohol to granulate, sieve, and press with 100MPa pressure to form discs. Insulate at 400°C for 60 minutes, raise the temperature to 1350°C at a heating rate of 5°C / min, hold for 3 hours, and cool to room temperature with the furnace. Moderately polish the upper and lower ends of the ceramic sheet, spray silver paste, and keep warm at 600°C for 60 minutes. Its X-ray diffraction analysis showed that only TiO was present in the sample 2 Mutually. Measured at room temperature: the varistor voltage is 7.8V / mm, and the dielectric constant is 7.4×10 4 (under 1KHz), the nonlinear co...

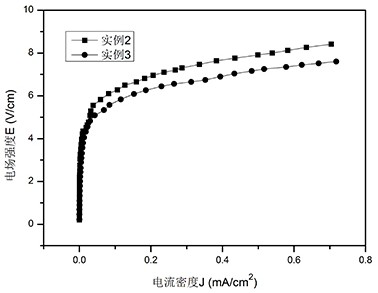

Embodiment 2

[0029] Micron-sized powder according to 99.35mol%TiO 2 , 0.3mol%SiO 2 , 0.2mol%Nb 2 o 5 , 0.15mol%Ho 2 o 3 Weigh the mixture and place it in an agate jar, add an appropriate amount of ethanol, and mill it on a planetary ball mill for 6 hours at a speed of 400r / min to make the powder evenly mixed. Filter the ball-milled slurry and put it in a drying oven at 70°C for 12 hours. Add 7wt% polyvinyl alcohol to granulate, sieve, and press with 110MPa pressure to form discs. Insulate at 400°C for 75 minutes, raise the temperature to 1400°C at a heating rate of 7°C / min, hold for 2.5 hours, and cool to room temperature with the furnace. Moderately polish the upper and lower ends of the ceramic sheet, spray silver paste, and keep warm at 620°C for 50 minutes. Measured at room temperature: the varistor voltage is 5.7V / mm, and the dielectric constant is 1.06×10 5 , the nonlinear coefficient is 4.7.

Embodiment 3

[0031] Micron-sized powder according to 99.05mol%TiO 2 , 0.3mol%SiO 2 , 0.2mol%Nb 2 o 5 , 0.45mol%Ho 2 o 3 Weigh the mixture and place it in an agate jar, add an appropriate amount of ethanol, and mill it on a planetary ball mill for 10 hours at a speed of 300r / min to make the powder evenly mixed. Filter the ball-milled slurry and put it into a drying oven at 70°C to dry for 14 hours. Add 6wt% polyvinyl alcohol to granulate, sieve, and press with 120MPa pressure to form discs. Insulate at 400°C for 70 minutes, raise the temperature to 1400°C at a heating rate of 6°C / min, hold for 2 hours, and cool to room temperature with the furnace. Moderately polish the upper and lower ends of the ceramic sheet, spray silver paste, and keep warm at 650°C for 45 minutes. Measured at room temperature: the varistor voltage is 6V / mm, and the dielectric constant is 1.88×10 5 , the nonlinear coefficient is 5.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com