Biodegradable composite film used for fresh keeping package of edible mushrooms and preparation method thereof

A biodegradable, fresh-keeping packaging technology, applied in coatings, hyaluronic acid coatings, alginic acid coatings, etc., can solve problems such as adverse effects, potential safety hazards, harmful gases in plastic films, reduce water loss and weight loss, and prolong storage. shelf life, respiration inhibition and post-growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

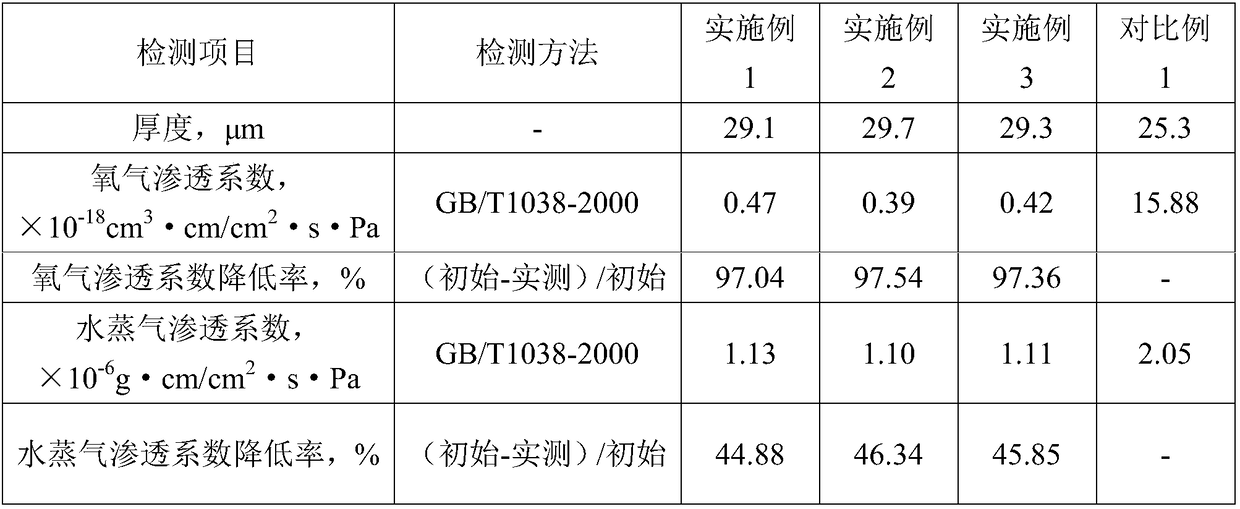

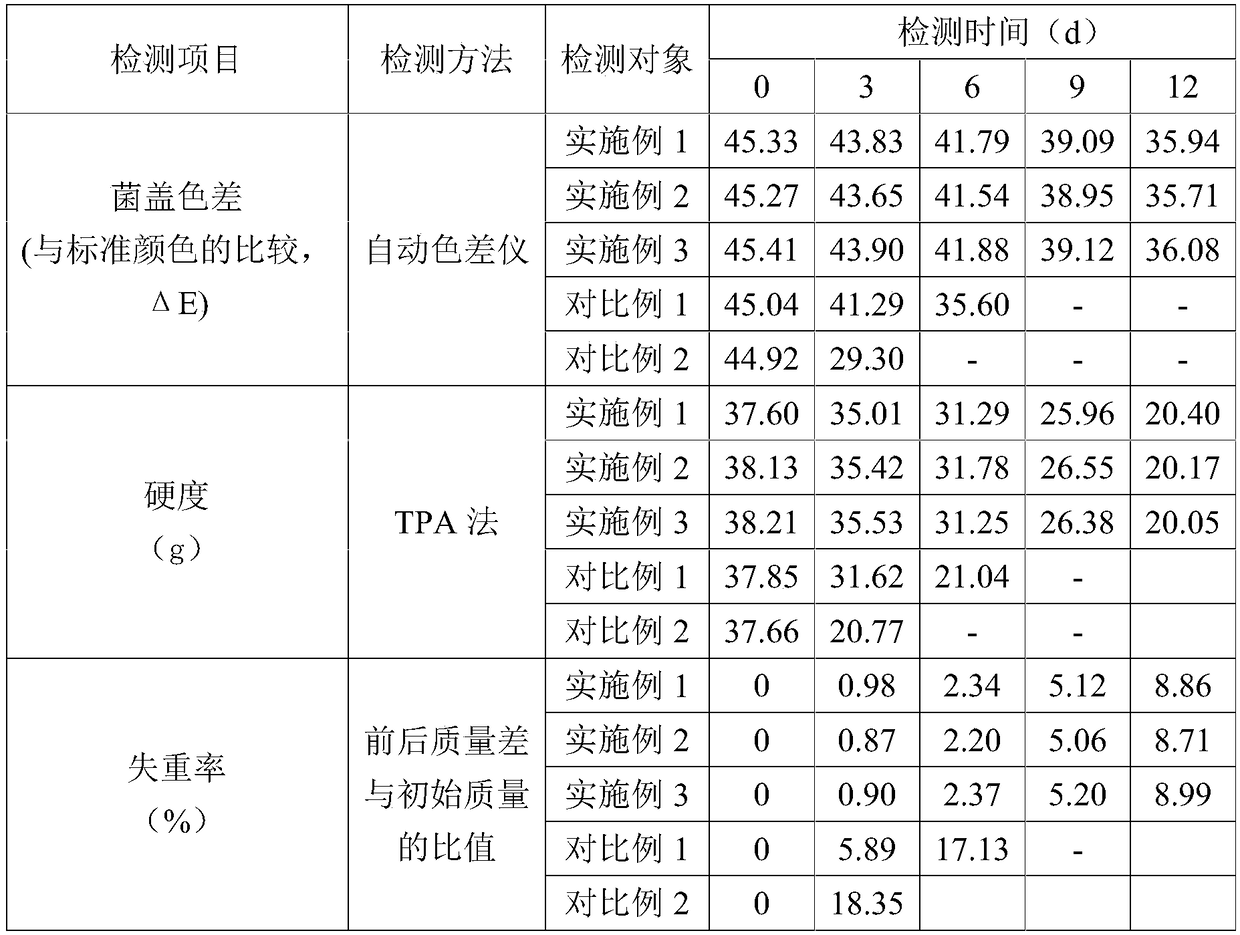

Embodiment 1

[0037] The biodegradable composite film for fresh-keeping packaging of edible fungi of this embodiment is prepared by the following method:

[0038] 1) Basement membrane pretreatment: take a polylactic acid film with a thickness of 25 μm as the basement membrane, immerse the basement membrane in a polyethyleneimine solution with a concentration of 1.0 g / L for 3 hours for amination, take it out, and wash it with deionized water And carry out blast drying at 45°C, then immerse in dilute hydrochloric acid with a mass concentration of 4.5% for 3min to acidify, take it out, wash with deionized water, and carry out blast drying at 45°C to obtain the modified base membrane;

[0039] 2) get chitosan and be dissolved in acetic acid aqueous solution (the mass concentration of acetic acid is 1.0%) and make the chitosan solution that concentration is 3.8g / L; Step 1) gained modified base film is completely submerged in gained chitosan In the solution for 9 minutes, after taking it out, wa...

Embodiment 2

[0043] The biodegradable composite film for fresh-keeping packaging of edible fungi of this embodiment is prepared by the following method:

[0044] 1) Basement membrane pretreatment: take a polylactic acid film with a thickness of 25 μm as the basement membrane, immerse the basement membrane in a polyethyleneimine solution with a concentration of 2.0 g / L for 2.5 hours for amination, take it out, and wash it with deionized water After cleaning, carry out blast drying at 45°C, then immerse in dilute hydrochloric acid with a mass concentration of 4.0%% for 4 minutes to acidify, then take it out, wash with deionized water, and carry out blast drying at 45°C. sexual basement membrane;

[0045] 2) get chitosan and be dissolved in acetic acid aqueous solution (the mass concentration of acetic acid is 1.0%) and make the chitosan solution that concentration is 3.5g / L; Step 1) gained modified base film is completely submerged in gained chitosan In the solution for 10 minutes, after ta...

Embodiment 3

[0049] The biodegradable composite film for fresh-keeping packaging of edible fungi of this embodiment is prepared by the following method:

[0050] 1) Basement membrane pretreatment: Take a polylactic acid film with a thickness of 25 μm as the basement membrane, immerse the basement membrane in a polyethyleneimine solution with a concentration of 1.5g / L for 2.5h for amination, take it out, and wash it with deionized water After cleaning, carry out blast drying at 45°C, then immerse in dilute hydrochloric acid with a mass concentration of 5.0% for 2 minutes for acidification, take it out, wash with deionized water, and carry out blast drying at 45°C to obtain modified basement membrane;

[0051] 2) get chitosan and be dissolved in acetic acid aqueous solution (the mass concentration of acetic acid is 1.0%) and make the chitosan solution that concentration is 4.0g / L; Step 1) gained modified base film is completely submerged in gained chitosan In the solution for 8 minutes, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com