Preparation method of dried mango

A technology of dried mangoes and mangoes, which is applied in the fields of fruit and vegetable preservation, the function of food ingredients, and the preservation of food ingredients as antimicrobials. Improve fruit quality and color, inhibit browning, and maintain flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

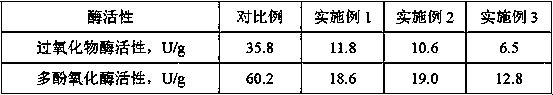

Examples

Embodiment 1

[0021] The preparation method of dried mango comprises the following steps:

[0022] S1: Wash 5 mature fresh mangoes and put them in the refrigerator at 1°C for use. After taking them out, they are placed in the permeate at a material-to-liquid ratio of 1:5. The permeate uses a sucrose solution with a mass fraction of 12% and adds a mass fraction 0.8% CaCl 2 With 0.16‰ of 2,3-epoxy-1-propanol, the infiltration temperature is 30°C, and the infiltration time is 0.5h. After the infiltration is completed, wash off the sugar on the surface with clean water, absorb the surface moisture and put it in a constant temperature drying box Carry out drying, the drying condition is 55 ℃, 24h, carry out - 18 ℃ low temperature preservation with polyethylene bag sealing;

[0023] S2: Prepare 25% ethephon diluent, and ripen the mangoes after thawing. Use 30mL ethephon diluent plus 60kg water for each ton of mango. The temperature for ripening is 18°C. Keep it relatively airtight for 20 hours, ...

Embodiment 2

[0028] The preparation method of dried mango specifically comprises the following steps:

[0029] Pretreatment: Wash 6 mature fresh mangoes and put them in a 4°C refrigerator for use. After taking them out, they are placed in the permeate according to the ratio of solid to liquid at 1:8. The permeate uses a sucrose solution with a mass fraction of 18%, and adds mass Fraction 1.5% CaCl 2, the infiltration temperature is 40°C, the infiltration time is 4h, after the infiltration is completed, wash off the sugar on the surface with clean water, absorb the surface moisture and put it in a constant temperature drying box for drying, the drying condition is 58°C, 48h, and use a polyethylene bag Sealed for low temperature storage at -25°C; CaCl 2 It can increase the hardness of fruits and vegetables and prevent them from softening after processing; the molecular weight of sucrose is 342. During the osmotic dehydration process, the low molecular weight solution has a higher osmotic pr...

Embodiment 3

[0036] The preparation method of dried mangoes includes: pretreatment, accelerated ripening, tablet making, color-protecting dipping, and drying, specifically including the following steps:

[0037] Pretreatment: Wash 5 mature fresh mangoes and put them in the refrigerator at 2°C for use. After taking them out, they are placed in the permeate according to the ratio of solid to liquid at 1:6. The permeate uses a sucrose solution with a mass fraction of 15%, and adds mass Fraction 1% CaCl 2 With 0.16‰ of 2,3-epoxy-1-propanol, the infiltration temperature is 35°C, and the infiltration time is 2h. After the infiltration is completed, the sugar on the surface is washed away with clean water, and the surface moisture is blotted and then placed in a constant temperature drying box. Drying, the drying condition is 56°C, 36h, sealed with polyethylene packaging bag for low temperature preservation at -20°C; CaCl 2 It can increase the hardness of fruits and vegetables and prevent them f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com