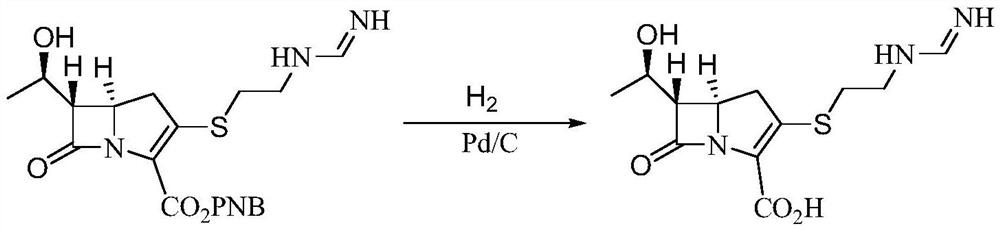

A kind of preparation method of palladium carbon catalyst for imipenem

A technology of palladium-carbon catalyst and imipenem, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of few preparation methods of precious metal palladium-carbon catalysts, etc. problems, to achieve the effect of improving equilibrium adsorption performance, improving utilization rate, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Reflux 20g of activated carbon with 0.5% glycine aqueous solution at 100°C for 1 hour, then wash the treated activated carbon with pure water until it is neutral, and dry it.

[0028] 2. Take 18g of activated carbon dried in step 1 and place it in an aqueous sodium acetate solution with a mass concentration of 0.5%, soak it for 4 hours at a temperature of 50°C, and filter to obtain a filter cake, which is beaten with pure water to obtain Activated carbon slurry.

[0029] 3. After dissolving palladium chloride containing 2g of palladium with hydrochloric acid with a mass concentration of 5%, sodium nitrite was added to obtain a modified active component solution, wherein the mass concentration of sodium nitrite was 1%.

[0030] 4. At a temperature of 20°C, add the modified active component solution obtained in step 3 dropwise to the activated carbon slurry in step 2, soak for 3 hours after the addition is completed, and then use NaOH with a mass concentration of 5% A...

Embodiment 2

[0033] 1. Reflux 20g of activated carbon with a glycine aqueous solution with a mass concentration of 1.0% at 90°C for 2 hours, then wash the treated activated carbon with pure water until it is neutral, and dry it.

[0034] 2. Take 18g of activated carbon dried in step 1 and place it in an aqueous sodium acetate solution with a mass concentration of 2.5%, soak it for 6 hours at a temperature of 20°C, and filter to obtain a filter cake, which is beaten with pure water to obtain Activated carbon slurry.

[0035] 3. After dissolving palladium chloride containing 2g of palladium in hydrochloric acid with a mass concentration of 10%, sodium nitrite was added to obtain a modified active component solution, wherein the mass concentration of sodium nitrite was 3%.

[0036] 4. At a temperature of 30°C, add the modified active component solution obtained in step 3 dropwise to the activated carbon slurry in step 2, soak for 5 hours after the addition is completed, and then use NaOH with...

Embodiment 3

[0039] 1. Reflux 20g of activated carbon with a glycine aqueous solution with a mass concentration of 1.5% at 95°C for 3 hours, then wash the treated activated carbon with pure water until it is neutral, and dry it.

[0040] 2. Take 18g of activated carbon dried in step 1 and place it in an aqueous potassium acetate solution with a mass concentration of 1.5%, soak it for 8 hours at a temperature of 30°C, and filter to obtain a filter cake, which is beaten with pure water to obtain Activated carbon slurry.

[0041] 3. After dissolving palladium chloride containing 2g of palladium with hydrochloric acid with a mass concentration of 7.5%, sodium nitrite was added to obtain a modified active component solution, wherein the mass concentration of sodium nitrite was 5%.

[0042] 4. At a temperature of 40°C, add the modified active component solution obtained in step 3 dropwise to the activated carbon slurry in step 2, soak for 8 hours after the addition is completed, and then use KOH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com