Embolization polymer, novel blood vessel embolization chemotherapy composite as well as preparation and application of novel blood vessel embolization chemotherapy composite

A vascular embolization and polymer technology, applied in the field of interventional medicine, can solve the problems of affecting the physicochemical properties and embolization performance of microspheres, unable to complete chemoembolization treatment in one step, and complicated embolization operation of emulsion-embolizing agent, etc. Wide temperature range and improved curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of microsphere

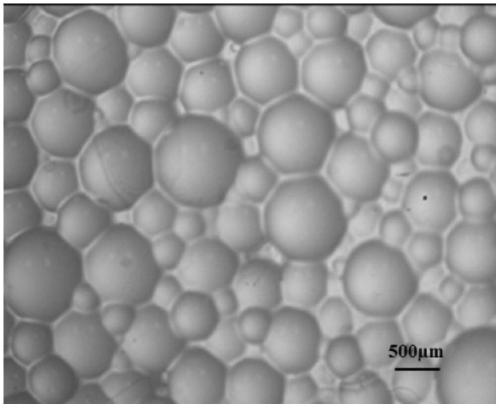

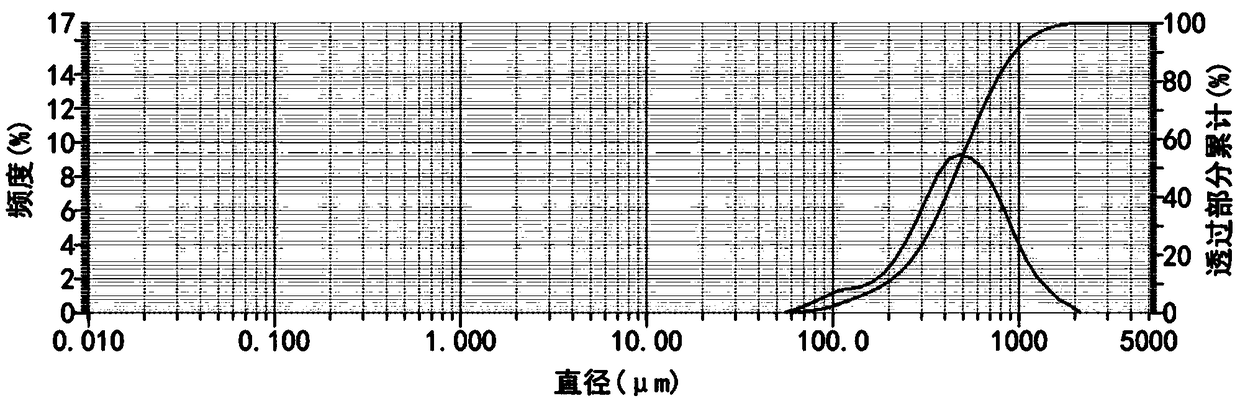

[0042] Using the reverse phase suspension polymerization method, add 60mL liquid paraffin and 60mg Span 80 into the three-necked flask, blow nitrogen to drive oxygen, and then dissolve 4.0g hydroxyethyl methacrylate, 2.0g acrylic acid, 60mg N,N'- Add methylenebisacrylamide (crosslinking agent) and 60mg ammonium persulfate (initiator) solution dropwise to the oil phase at 70°C, and after pre-crosslinking for 15 minutes, add 60mg tetramethylethylenediamine (catalyst) , after reacting for 2.5 hours under stirring at 200rpm, separate the microspheres, wash them, sieve out different specifications according to the particle size, and collect the particle size ranges (50~100μm, 100~300μm, 300~500μm, 500~700μm, 700~ 900μm, 900~1250μm and >1250μm) microspheres. Observe its shape, size and adhesion under an optical microscope, such as figure 1 As shown, the prepared microspheres are colorless, transparent, regular-shaped, circular ...

Embodiment 2

[0043] Embodiment 2: the preparation of microsphere

[0044] Using the reverse phase suspension polymerization method, add 60mL of liquid paraffin and 75mg of Span 80 into a three-necked flask, pass through nitrogen to drive oxygen, and then dissolve 4.0g of methyl methacrylate, 4.0g of 2-acrylamide-2-methyl Add propanesulfonic acid, 75mg N,N'-methylenebisacrylamide (crosslinking agent) and 75mg ammonium persulfate (initiator) solution dropwise to the oil phase at 80°C, pre-crosslink for 15min, then add 75 mg of tetramethylethylenediamine (catalyst), reacted for 4 hours under stirring at 300 rpm, separated the microspheres, washed, sieved out different specifications according to particle size, and collected various particle size ranges (50-100 μm, 100-300 μm, 300-500 μm, 500-700 μm, 700-900 μm, 900-1250 μm and >1250 μm) microspheres.

Embodiment 3

[0045] Example 3: Fracture deformation of microspheres

[0046] The physical property analyzer is equipped with a probe with a diameter of 6mm; the maximum bearing force of the sensing element is 5N, the minimum sensing force is 0.001N, and the accuracy is 0.01N; the sensing element collects 100 data points per second during the test. During the experiment, the probe of the physical property analyzer is controlled to compress the microspheres at a certain speed, and the resistance of the microspheres is converted into electrical signals through the sensor element, and the data is recorded online through the computer. The single microsphere compression test is used to test the stress and microsphere rupture of a single microsphere when subjected to a large deformation.

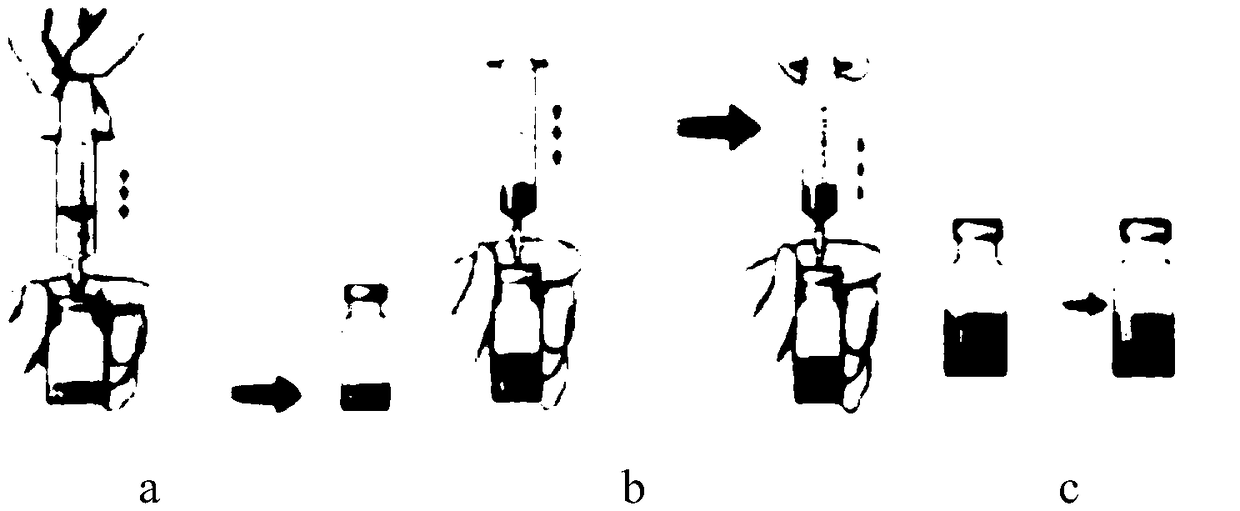

[0047] Take the single microspheres prepared in Example 1, with a particle size of 700 μm, and place them on the platform. The probe starts to press down from a height of 700 μm at a speed of 0.01 mm / s, and sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com