Antioxidant nano-fiber composite membrane containing nervilia fordii extract and preparation method and application thereof

A technology of nanofibers and blue skyflower, which is applied in the field of nanomaterials and food packaging materials, can solve the problems of anti-oxidation nano-packaging films that have not been reported, are difficult to dissolve in water, and limit applications, so as to improve poor water solubility and good biocompatibility performance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

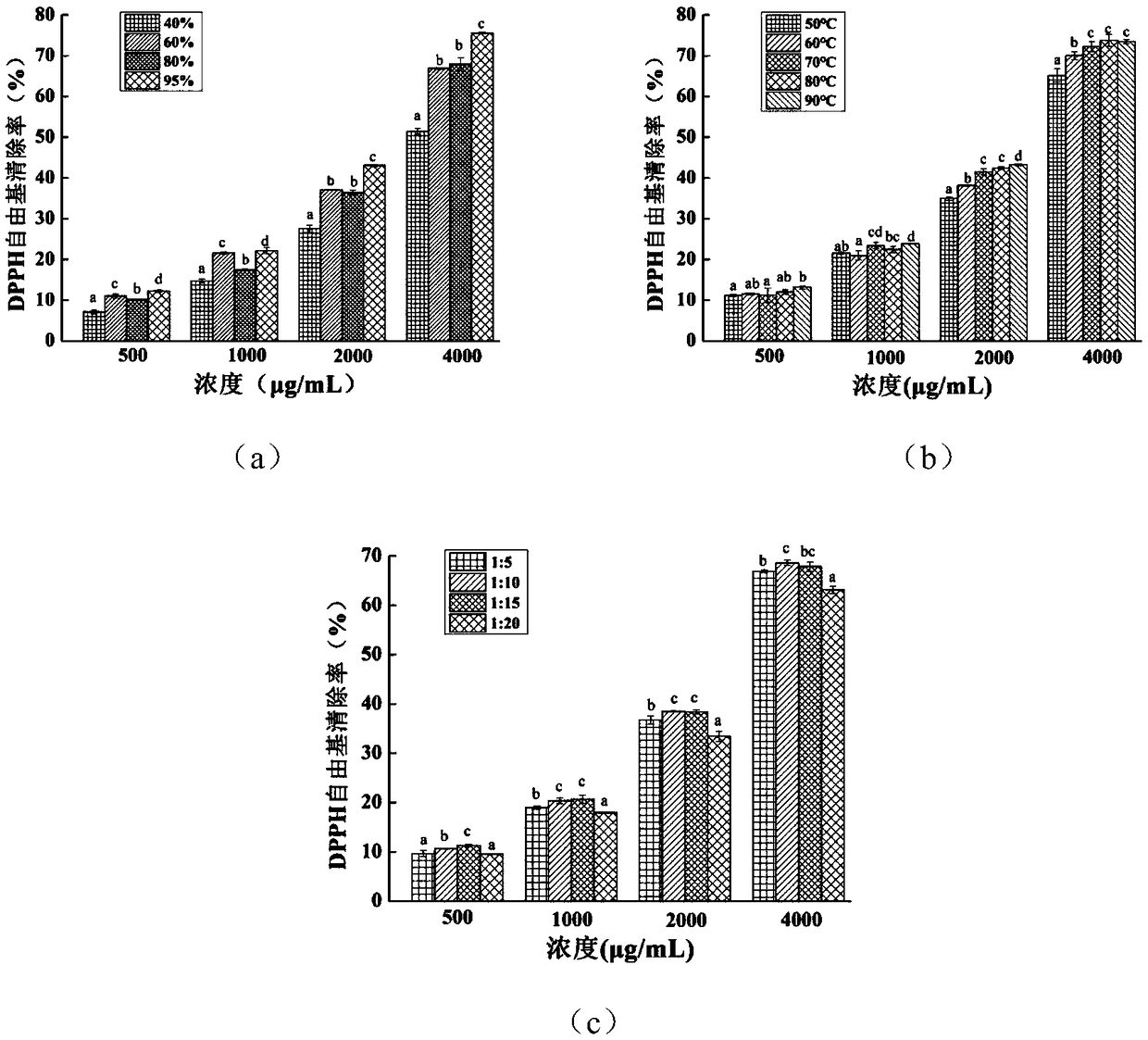

[0042] The optimization of the extraction conditions of blue skyflower, the specific steps are as follows:

[0043] (1) Select different conditions to extract the blue skyflower

[0044] Dissolve 20g of blue skyflower leaf powder in 40%, 60%, 80%, 95% ethanol solution, extract under reflux at 80°C for 2 times according to the ratio of solid to liquid 1:20, each time for 2h, and then concentrate by rotary evaporator to obtain Alcoholic extracts;

[0045] Dissolve 20g of blue skyflower leaf powder in 60% ethanol solution, at the extraction temperature of 50°C, 60°C, 70°C, 80°C, 90°C, reflux extraction twice according to the ratio of solid to liquid at 1:20, each time for 2h, and then pass Concentrate with a rotary evaporator to obtain each alcohol extract;

[0046] Dissolve 20g of blue skyflower leaf powder in 60% ethanol solution, reflux extraction at 70°C for 2 times according to the ratio of solid to liquid 1:5, 1:10, 1:15, 1:20, each time for 2h, and then pass through a ro...

Embodiment 2

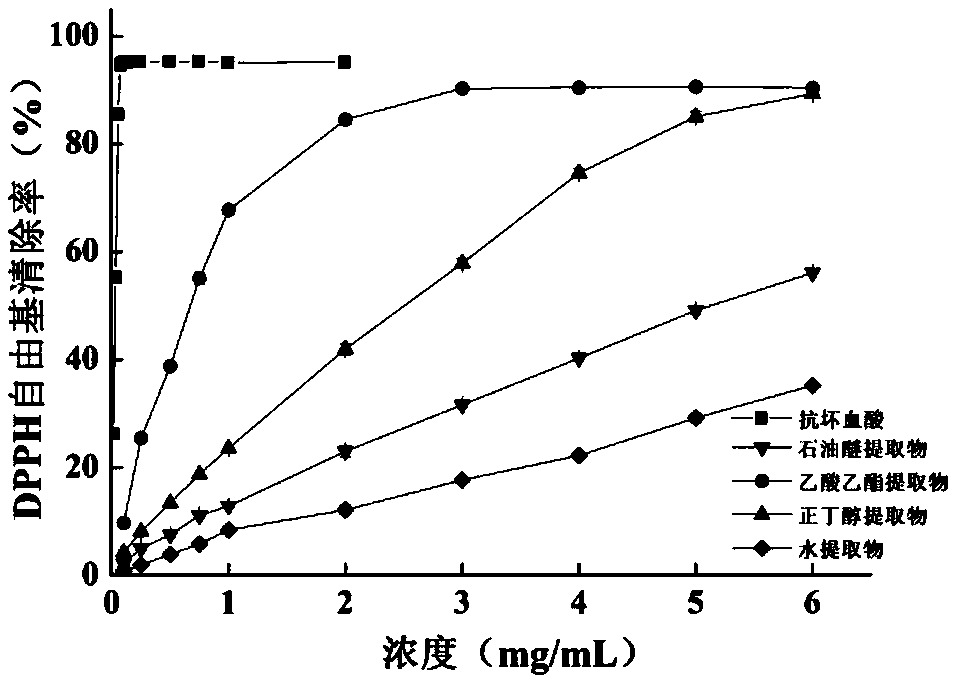

[0058] The antioxidant activity evaluation of the extracts of N. chinensis obtained by different extraction solvents, the specific operation steps are as follows:

[0059] (1) According to the method in Example 1, the alcoholic extract of S. radiata was prepared. The specific steps are as follows: 20g of blue skyflower powder is extracted under the conditions of ethanol volume fraction 56%, temperature 75°C, and solid-liquid ratio 1:14, and concentrated by a rotary evaporator to obtain an alcohol extract.

[0060] (2) Three kinds of extractants, petroleum ether, ethyl acetate and n-butanol, were selected, and according to the polarity of the extractants, extracts of blue skyflower with different polarities were sequentially obtained. The specific method is: add the ethanol extract obtained in (1) into 100mL water to dissolve, then add an equal amount of petroleum ether, extract for 4h, collect the upper layer, which is the petroleum ether extraction phase, and extract the lowe...

Embodiment 3

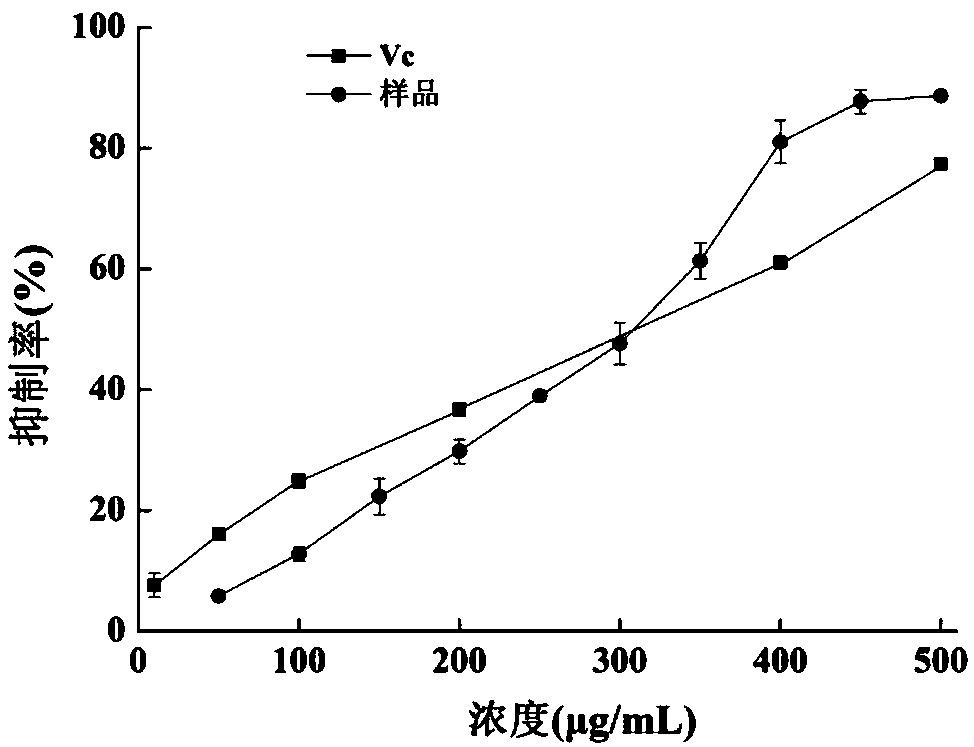

[0064] The total phenol content of different extraction phases was determined by the Folin phenol colorimetric method, and the specific steps were as follows:

[0065] (1) According to the method in Example 2, different extracts of blue skyflower were prepared.

[0066] (2) Take 100 μL of each extraction phase prepared with 70% ethanol at different concentrations (0.1mg / mL, 0.5mg / mL, 1mg / mL, 2mg / mL), add 0.5mL of Folinol reagent and 7.9mL of water, mix uniform. Protect from light for 5 min, then add 1.5 mL of 10% Na 2 CO 3 solution, after mixing, it was protected from light at room temperature for 2 h, and its absorbance was measured at 765 nm. Using different concentrations of gallic acid (20, 40, 60, 80, 100 μg / mL) as the standard substance, the total phenol content of each extraction phase was calculated by standard curves. The results of the determination of the total phenol content under the above process conditions are shown in Table 1. Through comparison, it is foun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com