Fabrication method for protein electrochemical imprint sensor of modified magnetic electrode by one-step deposition method

A technology for western blotting and modifying electrodes, which is applied in the fields of electroanalytical chemistry and protein recognition sensors to achieve the effects of simple preparation, improved conductivity and surface area, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

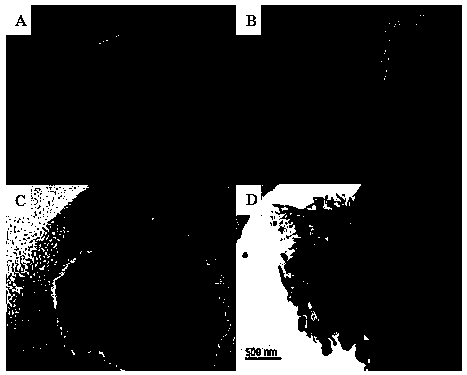

[0036] Graphene@Fe 3 o 4 Preparation of nanomaterials: 40 mg graphene powder was dispersed in 40 g ethylene glycol solution, ultrasonically dispersed, and 0.2 g FeCl was added sequentially 3 ·6H 2 O , 1.8 g sodium acetate, 0.8 g PEG 20000, fully dissolved, transferred to a 50mL reactor, heated at 200°C for 10 h; the resulting magnetic graphene@Fe 3 o 4 Nanomaterials were separated by a magnetic field, washed several times with ethanol and pure water in turn, and dried at 60°C. The prepared magnetic graphene@Fe 3 o 4 The morphology of nanomaterials is characterized by transmission electron microscopy, such as figure 2 As shown, it can be seen that Fe 3 o 4 Attached to the surface of graphene flakes.

Embodiment 2

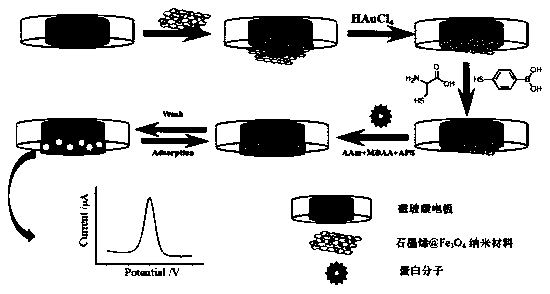

[0038] Preparation of electrodes for western blotting

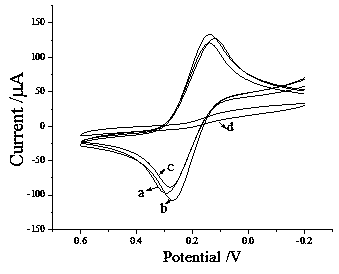

[0039] 0.1 mg of magnetic graphene@Fe prepared in Example 1 3 o 4 Nanomaterials dispersed in containing 0.2wt% HAuCl 4 In the buffer solution with a pH of 9.0, the polished magnetic glassy carbon electrode is used as the working electrode, and a three-electrode system is used, inserted into the solution, and the cyclic voltammetry scan is performed in the range of -1.4 to 0.6 V, and the scan is 6 circles, and the scan rate is 50mV / s. , rinse the modified electrode with ultrapure water;

[0040] Soak the above-mentioned modified electrode in a mixed solution containing 15 mmol / L mercaptophenylboronic acid and cysteine, self-assemble for 30 minutes, take out the electrode, rinse with ultrapure water, let stand, dry, and then soak in 0.5 mg / L mL of bovine hemoglobin solution, self-assembled for 60 min, took out the electrode, rinsed with ultrapure water, stood still, and dried;

[0041] 22.5 mg acrylamide, 3 mg methyle...

Embodiment 3

[0044] Soak the western blotting electrode prepared in Example 2 in BHb solutions of different concentrations, absorb for 40 min, take out the electrode, rinse with ultrapure water, let it stand, and dry it in a solution containing 0.1 mol / L KCl, 5 mmol / L The DPV scanning in the potassium ferricyanide solution, the scanning range is -0.2 ~ 0.6 V, the change of the peak current is monitored, and the DPV curves of different concentrations of BHb adsorbed by the MIP modified electrode are obtained ( Figure 4 ) and peak current curves with different equilibrium concentrations ( Figure 5 ),Such as Figure 4 as shown, Figure 4 The medium adsorption time is 40 min; the concentration increases from top to bottom: 0.0 μg / mL, 0.0001 μg / mL, 0.001 μg / mL, 0.01 μg / mL, 0.1 μg / mL, 0.5 μg / mL, 1.0 μg / mL, 5.0 μg / mL, 10 μg / mL, 50 μg / mL, 100 μg / mL, 500 μg / mL, 1000 μg / mL; with the increase of BHb concentration, the peak current signal gradually weakened, indicating that the imprinted holes on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com