A kind of gas-phase in-situ oxidation preparation method of MN-CE-FE-CO four-way catalytic function PPS filter material

A mn-ce-fe-co, gas-phase in-situ technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, separation methods, etc., can solve the central nervous system, immune system skin damage, high chemical agent treatment cost, poor uniformity of surface loading, etc., to achieve the effect of improving bonding strength and adsorption rate, reducing reaction conditions and parameter control requirements, and optimizing dispersion uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

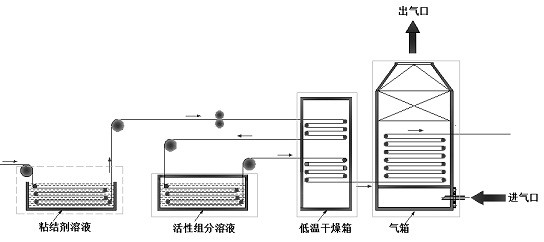

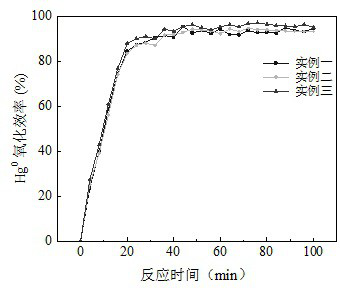

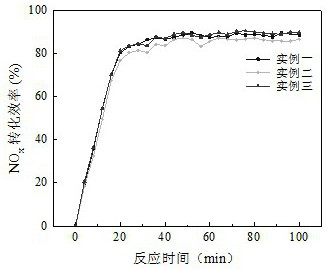

[0028] A gas-phase in-situ oxidation preparation method of a Mn-Ce-Fe-Co four-way catalytic function PPS filter material, comprising the following steps:

[0029] (1) For commercial PPS filter material, wash and dry the impurities on the surface of the filter material with deionized water, cut the washed PPS filter material into discs with a diameter of Ø25mm, weigh and record the quality parameters of the filter material, and place in 0.10g / Viscosity modification was carried out in mL organosilicon-modified polyurethane solution for 1h;

[0030] (2) Take out the impregnated and modified PPS filter material in step (1), drain it under ambient conditions, and dry it in a low-temperature drying oven at 100°C for 30 minutes;

[0031] (3) Weigh 0.35g Mn(NO 3 ) 2 , 0.723g Ce(NO 3 ) 3 , 0.07g Fe(NO 3 ) 2 , 0.0245g Co(NO 3 ) 2 Dissolve in 50mL deionized water, immerse the dried PPS filter material in step (2) into the salt solution of the catalytically active component of th...

example 2

[0036] A gas-phase in-situ oxidation preparation method of a Mn-Ce-Fe-Co four-way catalytic function PPS filter material, comprising the following steps:

[0037] (1) For commercial PPS filter material, wash the impurities on the surface of the filter material with deionized water and dry, cut the washed PPS filter material into discs with a diameter of Ø25mm, weigh and record the quality parameters of the filter material, and place in 0.08g / Viscosity modification was carried out in mL organosilicon-modified polyurethane solution for 1h;

[0038] (2) Take out the impregnated and modified PPS filter material in step (1), drain it under ambient conditions, and dry it in a low-temperature drying oven at 100°C for 30 minutes;

[0039] (3) Weigh 0.423g Mn(NO 3 ) 2 , 0.886g Ce(NO 3 ) 3 , 0.096g Fe(NO 3 ) 2 , 0.045g Co(NO 3 ) 2 Dissolve in 50mL deionized water, immerse the dried PPS filter material in step (2) in the salt solution of the catalytically active component of the...

example 3

[0044] A gas-phase in-situ oxidation preparation method of a Mn-Ce-Fe-Co four-way catalytic function PPS filter material, comprising the following steps:

[0045] (1) Select qualified commercial PPS filter material, wash and dry the impurities on the surface of the filter material with deionized water, cut the washed PPS filter material into discs with a diameter of Ø25mm, weigh and record the quality parameters of the filter material, and place in Viscosity modification in 0.15g / mL silicone-modified polyurethane solution for 1h;

[0046] (2) Take out the impregnated and modified PPS filter material in step (1), drain it under ambient conditions, and dry it in a low-temperature drying oven at 100°C for 30 minutes;

[0047] (3) Weigh 0.54g Mn(NO 3 ) 2 , 0.945g Ce(NO 3 ) 3 , 0.12g Fe(NO 3 ) 2 , 0.043g Co(NO 3 ) 2 Dissolve in 50mL deionized water, immerse the dried PPS filter material in step (2) in the salt solution of the catalytically active component of the Mn, Ce, Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com