Ceramic composite material

A ceramic composite material and powder technology, applied in the field of ceramic materials, can solve the problem that the ceramic composite material cannot meet the needs of use, and achieve the effects of high mechanical strength and chemical stability, high strength and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

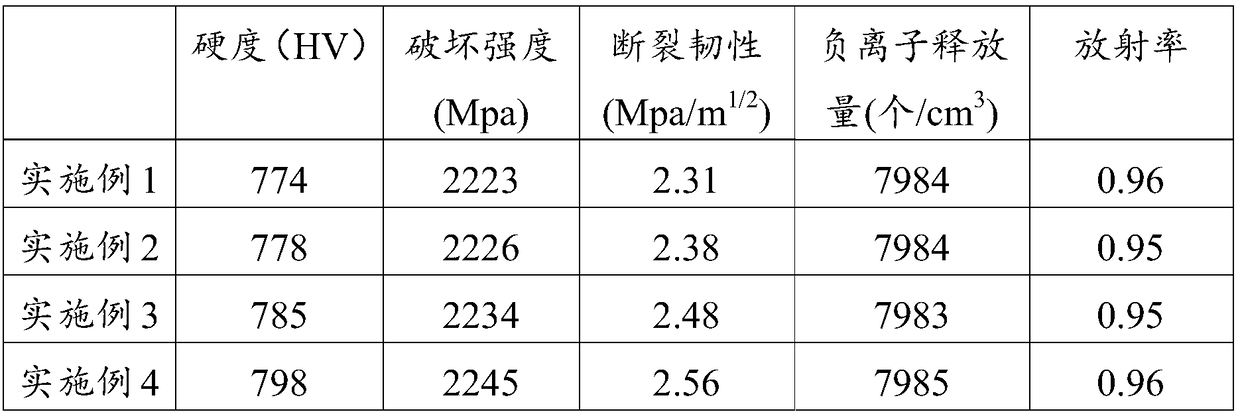

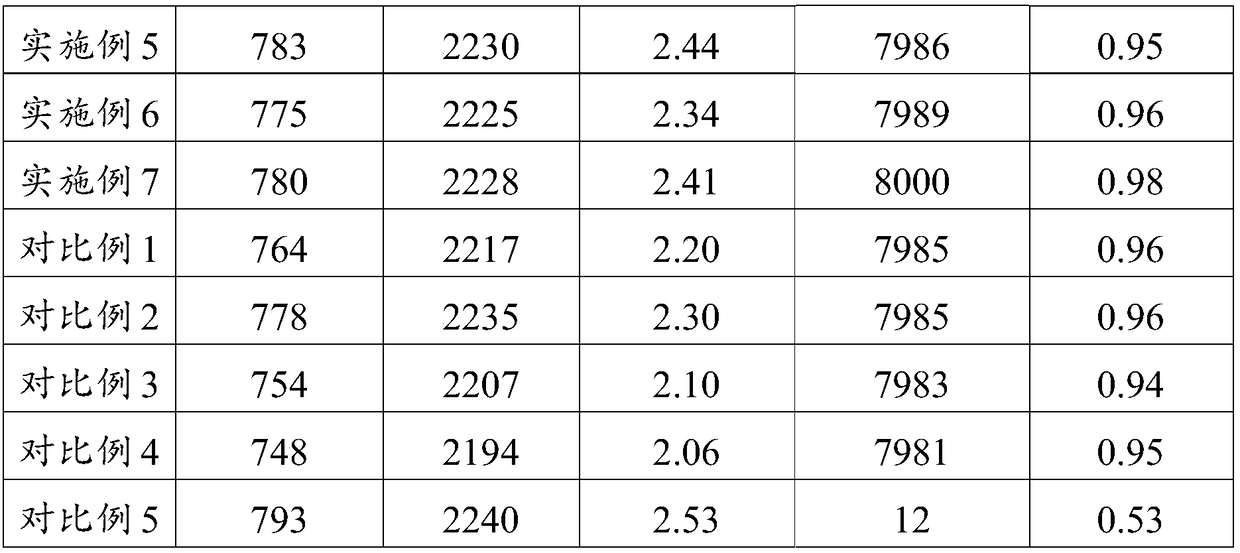

Examples

preparation example Construction

[0027] ZrB described in the present invention 2 -The preparation method of SiC composite material comprises the following steps:

[0028] After weighing zircon, boron oxide and activated carbon in proportion, they were dry-milled in a planetary ball mill for 2 hours and mixed evenly, and a green body with a diameter of 30mm was made at a pressure of 150Mpa. After drying at 120°C / 12h, the green body was buried In SiC powder, after vacuuming, carry out carbothermal reduction synthesis of ZrB in an atmosphere furnace with argon flow 2 - SiC powder.

Embodiment 1

[0030] As an embodiment of the ceramic composite material of the present invention, the ceramic composite material includes the following components by weight: ZrB 2 -75 parts of SiC, 25 parts of kaolin, 8 parts of nano-zirconia, 3 parts of nano-alumina, 2 parts of nano-magnesia, 1.5 parts of nano-titanium dioxide, 3.5 parts of carbon fiber, 4 parts of glass fiber, 6 parts of attapulgite, diatomaceous earth 12 parts, tourmaline 10 parts, medical stone 10 parts, polyethylene glycol 5 parts, silane coupling agent 3 parts.

[0031] The preparation method of the ceramic composite material of the present embodiment comprises the following steps:

[0032] 1) Pretreatment of carbon fiber and glass fiber prefabricated bodies; the pretreatment operation is: soaking in nitric acid with a mass fraction of 40% at a temperature of 50° C. for 6 hours, then washing with deionized water until neutral, and drying to constant weight reserve;

[0033] 2) Slurry preparation: weigh ZrB according t...

Embodiment 2

[0043] As an embodiment of the ceramic composite material of the present invention, the ceramic composite material includes the following components by weight: ZrB 2 -78 parts of SiC, 20 parts of kaolin, 6 parts of nano-zirconia, 3.5 parts of nano-alumina, 2.5 parts of nano-magnesia, 1 part of nano-titanium dioxide, 3 parts of carbon fiber, 4.5 parts of glass fiber, 6.5 parts of attapulgite, diatomaceous earth 10 parts, 12 parts of tourmaline, 12 parts of medical stone, 6 parts of polyethylene glycol, 4 parts of silane coupling agent. The ceramic composite material of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com