A high voltage resistant electrolyte and application thereof in high voltage supercapacitors

An electrolyte and voltage technology, applied in the field of electrochemistry, can solve the problems of reduced electrochemical performance, increased capacitor pressure, unreported usage, etc., and achieves the effects of improving energy density, reducing gas production, and being difficult to decompose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

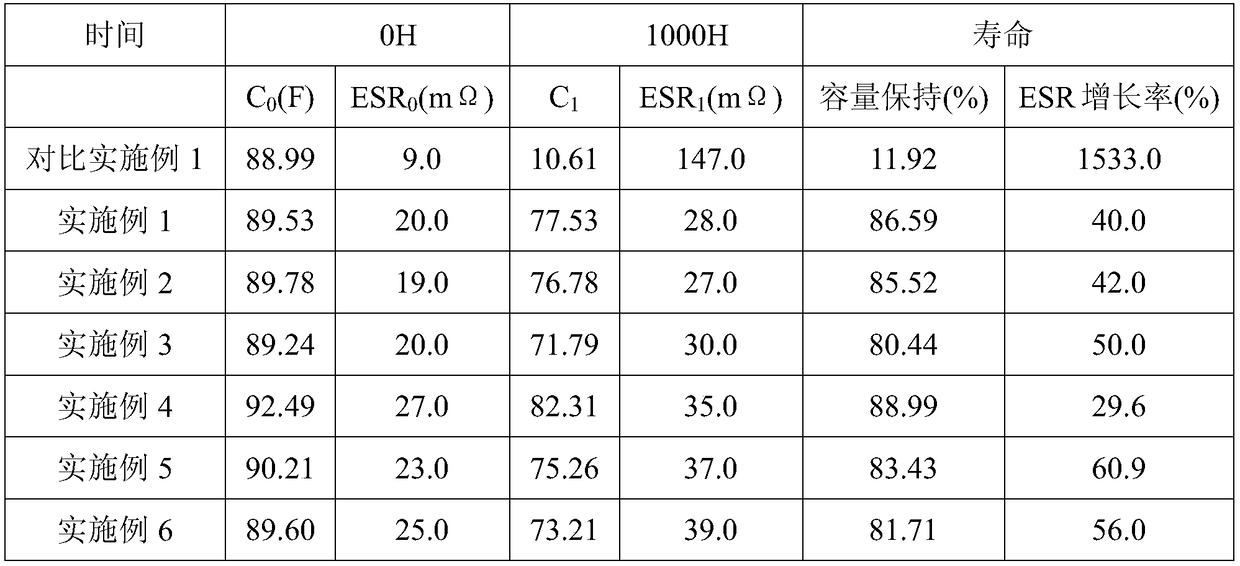

Examples

Embodiment 1

[0024] Using N,N-dimethylpyrrolidinium tetrafluoroborate and tetraethylphosphonium bis(trifluoromethanesulfonyl)imide as electrolytes (N,N-dimethylpyrrolidinium tetrafluoroborate The mass ratio of tetraethylphosphonium bis(trifluoromethanesulfonyl)imide salt as the electrolyte is 98:2), acetonitrile as the solvent, and 2,3-butanediol ester as the high-voltage additive to prepare a high-voltage resistant electrolyte. The concentration is 1mol / L, and the 2,3-butanediol ester accounts for 1% of the total mass of the electrolyte.

[0025] Complete the liquid injection in the glove box, seal it, and let it stand still.

Embodiment 2

[0027] Using N,N-dimethylpyrrolidinium tetrafluoroborate and tributylethylphosphonium bis(trifluoromethanesulfonyl)imide as electrolytes (N,N-dimethylpyrrolidinium tetrafluoroboron acid salt and tributylethylphosphonium bis(trifluoromethanesulfonyl)imide salt as the electrolyte (the mass ratio is 98:2), acetonitrile as the solvent, and ethyl isopropyl sulfone as the high-voltage additive to prepare a high-voltage resistant electrolyte , the concentration of the electrolyte is 1mol / L, and ethyl isopropyl sulfone accounts for 1% of the total mass of the electrolyte.

[0028] Complete the liquid injection in the glove box, seal it, and let it stand still.

Embodiment 3

[0030] Using P,P-dimethylpyrrolidinium tetrafluoroborate and tetrabutylphosphonium bis(trifluoromethanesulfonyl)imide as electrolytes (P,P-dimethylpyrrolidinium tetrafluoroborate The mass ratio of tetrabutylphosphonium bis(trifluoromethanesulfonyl)imide salt as the electrolyte is 95:5), acetonitrile as the solvent, ethyl isobutyl sulfone as the high-voltage additive, and the high-voltage resistant electrolyte is prepared, and the concentration of the electrolyte is 1mol / L, ethyl isobutyl sulfone accounts for 2% of the total mass of the electrolyte.

[0031] Complete the liquid injection in the glove box, seal it, and let it stand still.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com