Fabrication method and application of tetracycline antibiotic molecular imprinting electrochemical sensor

A technology of molecular imprinting and antibiotics, which is applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of reduced sensitivity of electrochemical sensors, limiting the application of molecularly imprinted membranes, and reducing stability and reproducibility, and achieves excellent electronic performance. The effect of transmission ability, lower testing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of NiFeN-nanoarray

[0031] (1) The disposable disposable electrode is ultrasonically cleaned with dilute hydrochloric acid, anhydrous ethanol and deionization to remove the oxide layer and surface impurities of the disposable disposable electrode;

[0032] (2) Weigh 1 mmol Ni(NO 3 ) 2 and Fe(NO 3 ) 3 A mixture of 3 mmol urea CO (NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water, stir until it becomes clear, and then transfer it to a 50 mL polytetrafluoroethylene reactor;

[0033] (3) Putting the disposable disposable electrode processed in step (1) into the solution in the reaction kettle in step (2), and reacting at a temperature of 100 ° C for 12 hours to prepare nickel-iron bimetallic layered hydrogen oxide nanosheet array precursor electrode;

[0034] (4) Insert the nickel-iron bimetallic hydroxide nanosheet array precursor electrode obtained in step (3) into a phosphate buffer solution PBS containing dopamine, ammoniu...

Embodiment 2

[0036] Example 2 Preparation of NiFeN-nanoarray

[0037] (1) The disposable disposable electrode is ultrasonically cleaned with dilute hydrochloric acid, anhydrous ethanol and deionization to remove the oxide layer and surface impurities of the disposable disposable electrode;

[0038] (2) Weigh 2 mmol Ni(NO 3 ) 2 and Fe(NO 3 ) 3 A mixture of 6 mmol urea CO (NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water, stir until it becomes clear, and then transfer it to a 50 mL polytetrafluoroethylene reactor;

[0039] (3) put the disposable disposable electrode processed in step (1) into the solution in the reaction kettle in step (2), and react at a temperature of 110 ° C for 11 hours to prepare nickel-iron bimetallic layered hydrogen oxide nanosheet array precursor electrode;

[0040] (4) Insert the nickel-iron bimetallic hydroxide nanosheet array precursor electrode obtained in step (3) into a phosphate buffered solution PBS containing dopamine, ammonium per...

Embodiment 3

[0042] Example 3 Preparation of NiFeN-nanoarray

[0043] (1) The disposable disposable electrode is ultrasonically cleaned with dilute hydrochloric acid, anhydrous ethanol and deionization to remove the oxide layer and surface impurities of the disposable disposable electrode;

[0044] (2) Weigh 3 mmol Ni(NO 3 ) 2 and Fe(NO 3 ) 3 A mixture of 9 mmol urea CO (NH 2 ) 2 , put it into a 50 mL beaker, add 30 mL of deionized water, stir until it becomes clear, and then transfer it to a 50 mL polytetrafluoroethylene reactor;

[0045] (3) Put the disposable disposable electrode processed in step (1) into the solution in the reaction kettle in step (2), and react at a temperature of 130 ° C for 9 hours to prepare nickel-iron bimetallic nitride nanometers Sheet array precursor electrodes;

[0046] (4) Insert the nickel-iron bimetallic hydroxide nanosheet array precursor electrode obtained in step (3) into a phosphate buffered solution PBS containing dopamine, ammonium persulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

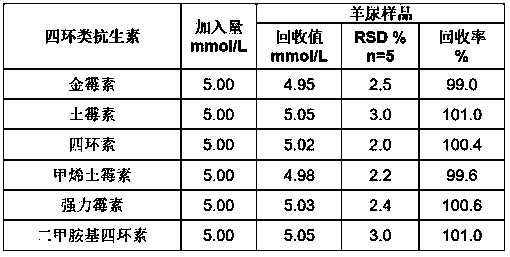

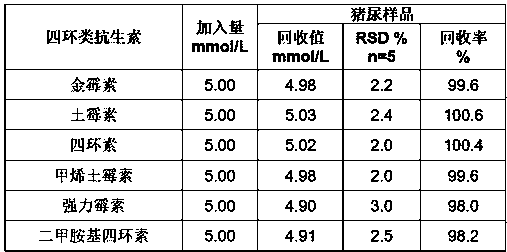

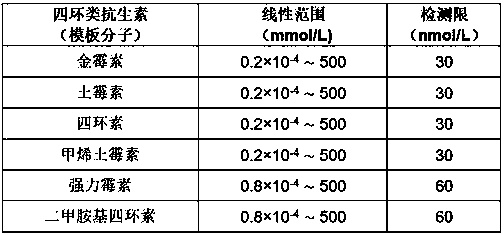

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com