Nitrogen-doped mesoporous carbon prepared by using calcium cyanamide as well as preparation method and application of nitrogen-doped mesoporous carbon

A technology of calcium cyanamide and porous carbon, applied in chemical instruments and methods, carbon preparation/purification, and hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of slow reaction speed and catalyst preparation method of homogeneous acid-base catalysis Complicated, not suitable for large-scale production and other issues, to achieve excellent catalytic activity, rich surface active sites, simple and repeatable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Grind 25g of wheat flour and 0.5g of calcium cyanamide thoroughly, add 15mL of water, knead into a dough and extrude into strips (4mm in particle size, 5cm in length), leave it at room temperature for 8h, and then put it in an oven at 110°C for 12 hours to get Carbon precursor; then put the carbon precursor into a tube furnace, and treat it at 850°C for 3h under a nitrogen atmosphere, with a gas flow rate of 30mL / min and a heating rate of 3.5°C / min, to obtain a nitrogen-doped mesoporous carbon material.

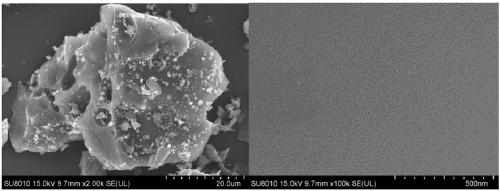

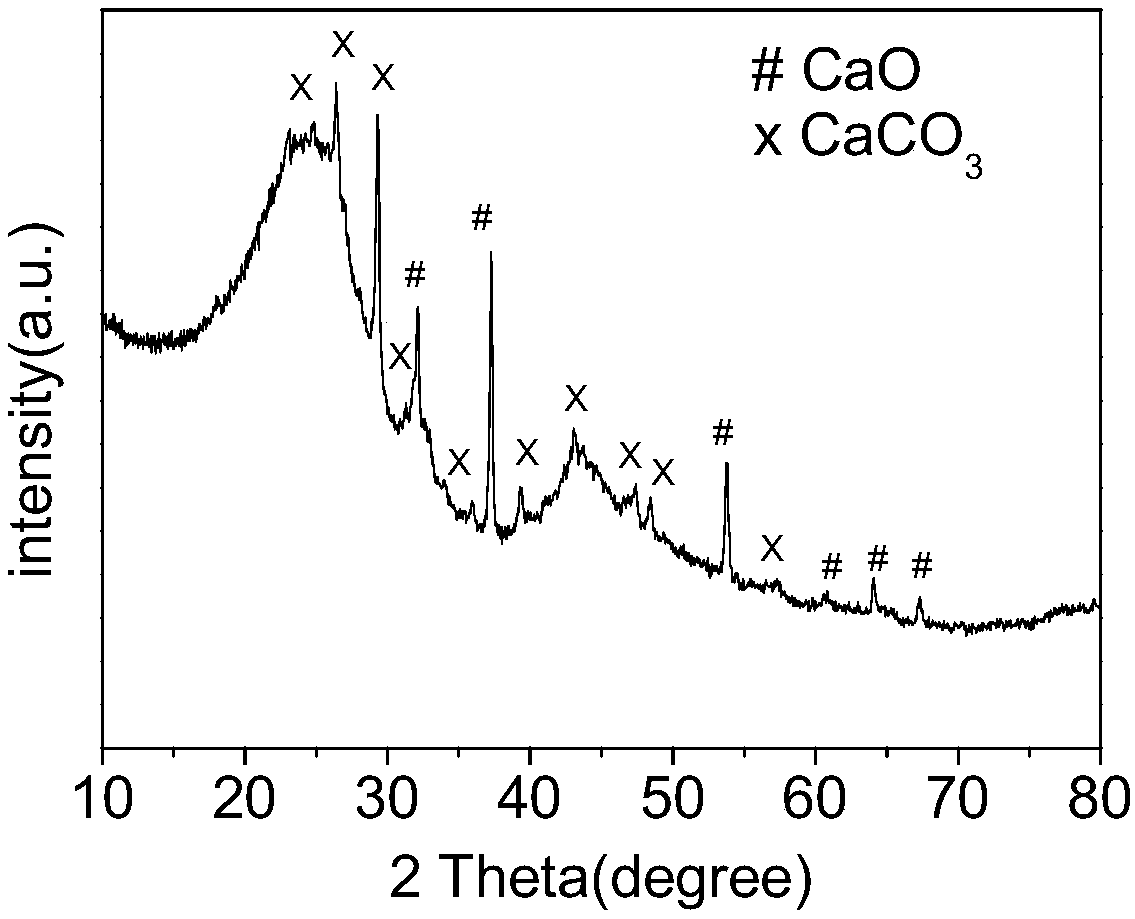

[0035] The scanning electron microscope figure and XRD figure of the nitrogen-doped mesoporous carbon that embodiment 1 makes are respectively as follows figure 1 and 2 shown by figure 1 and 2 It can be seen that the small particles on the surface of the material are calcium carbonate and calcium oxide, and calcium oxide is the main basic site; the appearance of the nitrogen-doped mesoporous carbon prepared in Example 1 is as follows image 3 shown.

Embodiment 2

[0037] Grind 25g of wheat flour and 2.5g of calcium cyanamide thoroughly, add 18mL of water, knead into a dough and extrude into strips (particle size 4mm, length 5cm), leave it at room temperature for 8h, and then put it in an oven at 110°C for 12 hours to get Carbon precursor; then put the carbon precursor into a tube furnace, and treat it at 850°C for 3h under a nitrogen atmosphere, with a gas flow rate of 30mL / min and a heating rate of 3.5°C / min, to obtain a nitrogen-doped mesoporous carbon material.

Embodiment 3

[0039] Grind 20g of glucose and 4g of calcium cyanamide thoroughly, add 5mL of water, knead and shape, then place it at room temperature for 8 hours, and then put it in an oven to dry at 110°C for 8 hours to obtain a precursor; put the dried sample into a tube furnace, The nitrogen-doped mesoporous carbon material was obtained by treating at 700° C. for 3 h in a nitrogen atmosphere with a heating rate of 3° C. / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com