Degradable multifunctional agricultural mulching film

A mulching film and polymer technology, applied in application, plant protection, gardening, etc., can solve the problems of uniform dispersion and unsatisfactory compatibility of polymer resins, achieve good market application prospects, less environmental damage, and prolong the action time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

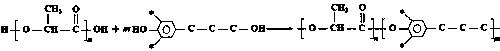

Method used

Image

Examples

Embodiment 1

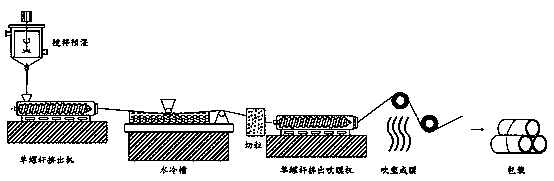

[0022] The raw materials are mixed and pre-mixed according to the predetermined ratio, added to a single-screw extrusion granulator for extrusion molding, cooled and cut into pellets, blown into a film in a single-screw extrusion blown film machine, and dried. The manufacturing process such as figure 1 shown. Among them, the granulation temperature is 145-150°C, and the film blowing temperature is 145-150°C. Described material ratio is described in the following table:

[0023]

Embodiment 2

[0025] According to the standard GB / T1040.1-2006 / ISO 527-1:1993, the elongation at break of samples 1#-6# in Example 1 was tested. The experimental results show that the addition of plasticizer significantly increases the elongation at break of the film compared to the film without plasticizer. Among them, the elongation at break of tricresyl phosphate, dibutyl phthalate and dioctyl phthalate was higher than that of pentaerythritol and epoxy soybean oil, and compared with the film without plasticizer, they increased respectively. 34.5%, 22.6% and 27.2%.

Embodiment 3

[0027] Numbering

[0028] The obtained sample was placed in an aqueous solution of sodium hydroxide with pH=13 at room temperature for hydrolysis performance test, and the accurate mass of the sample before the test was recorded. After standing for 45 days, the samples were washed with water, dried in vacuum, and weighed again. The experimental results show that the weight loss of sample 7# is 7%, which means that the sample has begun to degrade. Wherein, adopt mass loss method to measure degradability, concrete formula is: d W =(W 0 -W) / W 0 ×100%, where, W 0 , W are the mass of the film before and after degradation respectively, d W is the weight loss percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

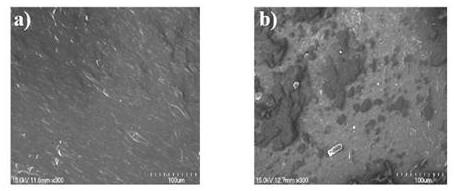

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com