Manufacturing method of organic electroluminescence element and organic electroluminescence element

The technology of an electroluminescent element and a manufacturing method is applied in the manufacture of organic electroluminescent elements and the field of organic electroluminescent elements, and can solve problems such as inability to reduce manufacturing costs, lower output, deformation of flexible substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0277] "Preparation of Organic EL Element 101"

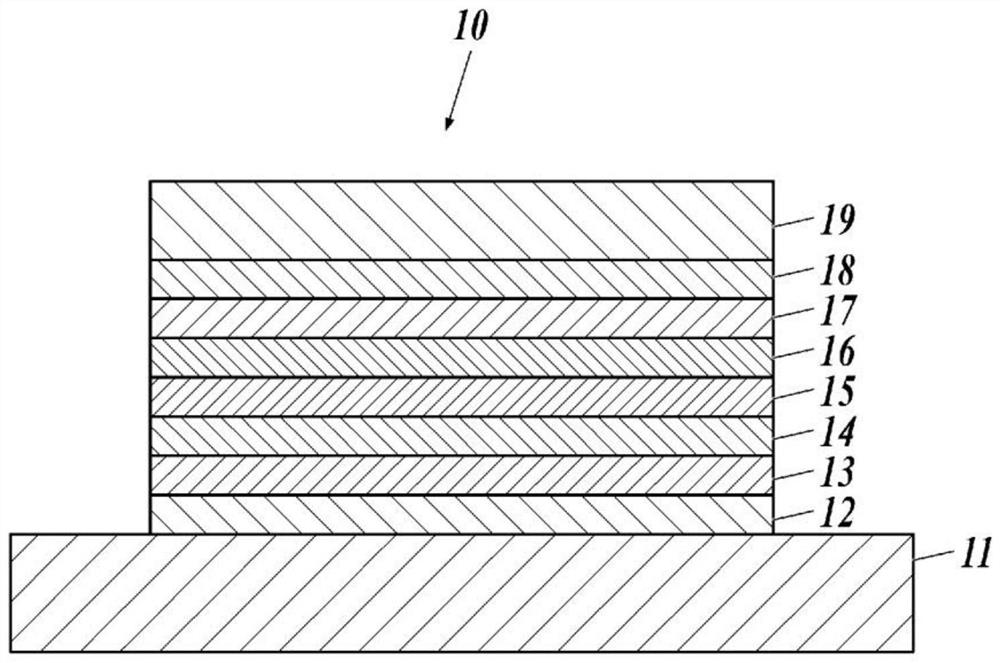

[0278] Anode / hole injection layer / hole transport layer / light emitting layer / blocking layer / electron transport layer / electron injection layer / cathode are laminated and sealed on a base material as follows to prepare a bottom emission type organic EL element 101 .

[0279] (preparation of base material)

[0280] First, on the entire surface of a polyethylene naphthalate film (manufactured by Teijin DuPont Co., Ltd., hereinafter abbreviated as PEN) on which the anode is formed, atmospheric pressure plasma having the structure described in JP-A-2004-68143 is used. discharge treatment device, formed containing SiO x Inorganic gas barrier layer, and make the layer thickness 500nm. Thus, the oxygen transmission rate of 0.001mL / (m 2 24h) or less, the water vapor transmission rate is 0.001g / (m 2 24h) or less flexible substrates having gas barrier properties.

[0281] (formation of anode)

Embodiment 2

[0345] "Preparation of Organic EL Element 201"

[0346] In the preparation of the organic EL element 101 in Example 1 above, except that the material contained in the coating solution for barrier layer formation was changed to HS-12, the organic EL element 201 was prepared in the same manner.

[0347] "Preparation of Organic EL Element 202"

[0348] In the production of the organic EL element 101 of the above-mentioned Example 1, the organic EL element 202 was produced in the same manner except that the formation method of the barrier layer was changed as described below.

[0349] (formation of barrier layer)

[0350] The substrate on which the light-emitting layer was formed was placed in a vacuum evaporation apparatus without being exposed to the atmosphere. In addition, put HS-12 into a molybdenum resistance heating boat and load it into a vacuum evaporation device, and depressurize the vacuum chamber to 4×10 -5 After Pa, the boat was energized and heated, and HS-12 was ...

Embodiment 3

[0358] "Preparation of Organic EL Element 301"

[0359] In the preparation of the organic EL element 101 in Example 1 above, except that the material contained in the coating solution for barrier layer formation was changed to HS-2, the organic EL element 301 was prepared in the same manner.

[0360] "Preparation of Organic EL Element 302 and Organic EL Element 303"

[0361] In the preparation of the organic EL element 101 of Example 1 above, the materials contained in the coating liquid for barrier layer formation were changed to those shown in Table 5, and the method of forming the electron transport layer was changed to the following, except Otherwise, the organic EL element 302 and the organic EL element 303 were produced in the same manner.

[0362] (Formation of electron transport layer)

[0363] The substrate on which the barrier layer was formed was loaded into a vacuum evaporation apparatus without being exposed to the atmosphere. In addition, compound A was put into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com