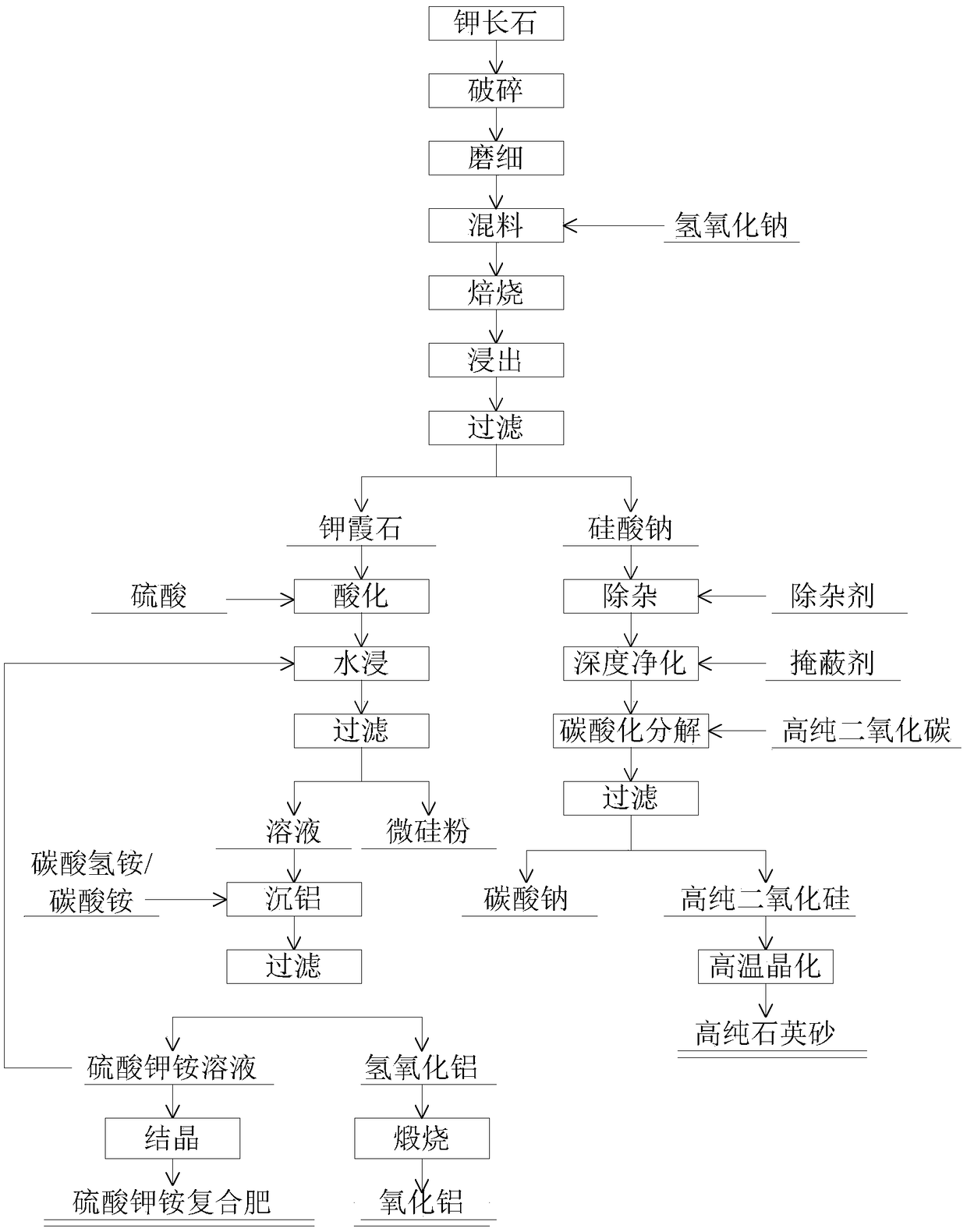

High value-added method for comprehensively utilizing silicon, aluminum and potassium in potassium feldspar ore

A high value-added, potassium feldspar technology, applied in the direction of chemical instruments and methods, applications, silicon oxide, etc., can solve the problems of large discharge of filter residue, difficulty in potassium, high equipment requirements, etc., to reduce discharge of residue, reduce waste, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The potash feldspar ore is crushed, pulverized to below 80 μm, and mixed evenly with sodium hydroxide. The quantity ratio of potash feldspar ore and sodium hydroxide substance is: the silicon dioxide in potash feldspar ore completely reacts with sodium hydroxide to produce sodium silicate and the amount of sodium hydroxide substance consumed is calculated as 1, and potassium Feldspar ore: Sodium hydroxide is 1:1.5. The mixed materials are roasted at 400℃ and kept for 3h.

[0046] The roasted clinker obtained after the reaction was dissolved by adding 3 times the mass of 0.5mol / L sodium hydroxide solution, stirred at 50°C for 40 minutes, and filtered. The filtrate is an alkali solution containing sodium silicate, and the filter residue is potassium nepheline, washed Wait for subsequent treatment after drying.

[0047] Add the clinker leaching solution to the impurity removing agent calcium oxide, control its concentration to 0.1g / L, and place it in the reaction kettle, and h...

Embodiment 2

[0054] The potash feldspar ore is crushed, pulverized to below 80 μm, and mixed evenly with sodium hydroxide. The quantity ratio of potash feldspar ore and sodium hydroxide substance is: the silicon dioxide in potash feldspar ore completely reacts with sodium hydroxide to produce sodium silicate and the amount of sodium hydroxide substance consumed is calculated as 1, and potassium Feldspar ore: Sodium hydroxide is 1:1.2, roast the mixed material at 500℃ and keep it warm for 1.5h.

[0055] The roasted clinker obtained after the reaction was dissolved by adding 4 times the mass of 0.3mol / L sodium hydroxide solution, and stirred at 60°C for 80% m in, filter, the filtrate is an alkali solution containing sodium silicate, and the filter residue is potassium cremite, which is washed and dried for subsequent treatment.

[0056] Add the clinker leaching solution to the impurity removal agent calcium chloride, control its concentration to 0.1g / L, and place it in the reaction kettle, and hy...

Embodiment 3

[0063] The potash feldspar ore is crushed, pulverized to below 80 μm, and mixed evenly with sodium hydroxide. The quantity ratio of potash feldspar ore and sodium hydroxide substance is: the silicon dioxide in potash feldspar ore completely reacts with sodium hydroxide to produce sodium silicate and the amount of sodium hydroxide substance consumed is calculated as 1, and potassium Feldspar ore: Sodium hydroxide is 1:1, roast the mixed material at 600℃ and keep it for 0.5h.

[0064] The roasted clinker obtained after the reaction was dissolved by adding 5 times the mass of 0.2mol / L sodium hydroxide solution, stirred at 95°C for 60 minutes, and filtered. The filtrate was an alkali solution containing sodium silicate, and the filter residue was potassium nepheline, washed Wait for subsequent treatment after drying.

[0065] Add the clinker leaching solution to the impurity removing agent calcium silicate, control its concentration to 0.1g / L, and place it in the reaction kettle, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com