Corrosion-resisting coating and preparation method thereof

A corrosion-resistant coating technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of outdoor materials such as large damage, high protection cost, easy cracking or peeling, etc., to achieve good corrosion resistance, use Long life, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

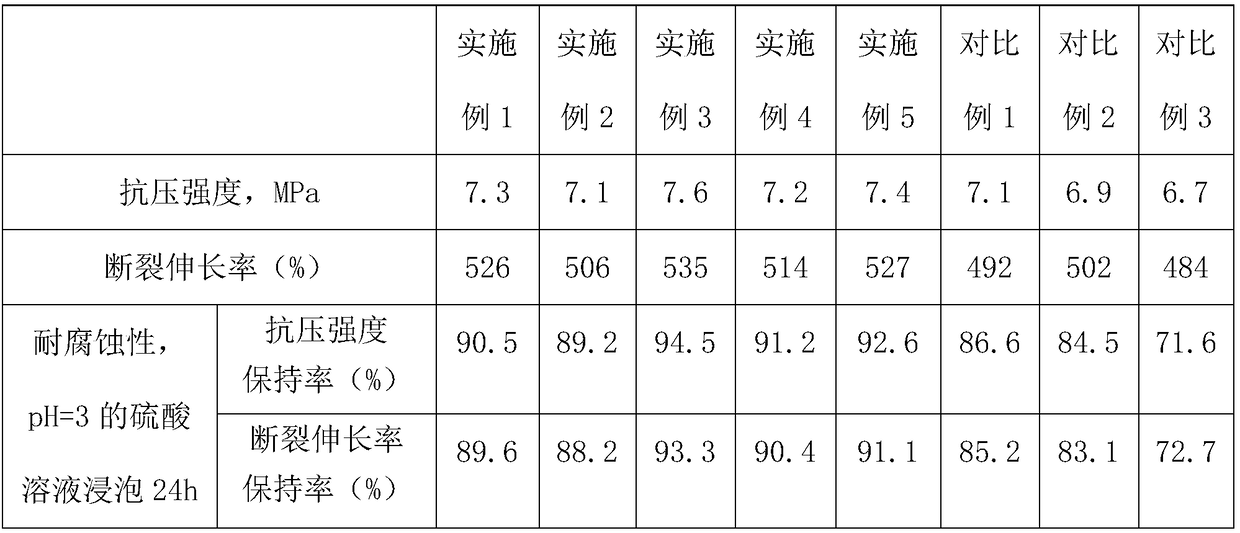

Examples

Embodiment 1

[0021] A corrosion-resistant coating, comprising the following raw materials in parts by weight: 60 parts of water-based polyurethane resin, 30 parts of acrylic emulsion, 20 parts of propylene glycol butyl ether, 12 parts of dioctyl phthalate, 6 parts of polytetrafluoroethylene fiber, phosphoric acid 3 parts of zinc, 3 parts of calcium carbonate, 2 parts of graphite powder, 3 parts of silicon dioxide, 5 parts of sodium fluorosilicate, 3 parts of 4-propenyloxy-2-hydroxybenzophenone, 2 parts of silane coupling agent, 10 parts of sodium carboxymethyl cellulose, 30 parts of deionized water.

[0022] Wherein, the acrylic emulsion is composed of pure acrylic emulsion and silicone acrylic emulsion in a weight ratio of 1:2.

[0023] Wherein, the polytetrafluoroethylene fiber has a length of 0.5 mm and a diameter of 1 μm.

[0024] Wherein, the silane coupling agent is KH-560.

[0025] In the present embodiment, the preparation method of the corrosion-resistant coating, the steps are ...

Embodiment 2

[0030] A corrosion-resistant coating, comprising the following raw materials in parts by weight: 65 parts of water-based polyurethane resin, 35 parts of acrylic emulsion, 22 parts of propylene glycol butyl ether, 14 parts of dioctyl phthalate, 7 parts of polytetrafluoroethylene fiber, phosphoric acid 4 parts of zinc, 4 parts of calcium carbonate, 3.5 parts of graphite powder, 5 parts of silicon dioxide, 8 parts of sodium fluorosilicate, 5 parts of 4-propenyloxy-2-hydroxybenzophenone, 4 parts of silane coupling agent, 18 parts of sodium carboxymethyl cellulose, 45 parts of deionized water.

[0031] Wherein, the acrylic emulsion is composed of pure acrylic emulsion and silicone acrylic emulsion in a weight ratio of 1:2.

[0032] Wherein, the polytetrafluoroethylene fiber has a length of 0.8 mm and a diameter of 1.5 μm.

[0033] Wherein, the silane coupling agent is KH-560.

[0034] In the present embodiment, the preparation method of the corrosion-resistant coating, the steps ...

Embodiment 3

[0039] A corrosion-resistant coating, comprising the following raw materials in parts by weight: 70 parts of water-based polyurethane resin, 40 parts of acrylic emulsion, 25 parts of propylene glycol butyl ether, 16 parts of dioctyl phthalate, 8 parts of polytetrafluoroethylene fiber, phosphoric acid 4.5 parts of zinc, 4.5 parts of calcium carbonate, 3 parts of graphite powder, 4.5 parts of silicon dioxide, 7 parts of sodium fluorosilicate, 4.5 parts of 4-propenyloxy-2-hydroxybenzophenone, 3.5 parts of silane coupling agent, 15 parts of sodium carboxymethyl cellulose, 40 parts of deionized water.

[0040] Wherein, the acrylic emulsion is composed of pure acrylic emulsion and silicone acrylic emulsion in a weight ratio of 1:2.

[0041] Wherein, the polytetrafluoroethylene fiber has a length of 0.8 mm and a diameter of 1.5 μm.

[0042] Wherein, the silane coupling agent is KH-560.

[0043] In the present embodiment, the preparation method of the corrosion-resistant coating, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com