A nanoparticle with grain boundaries, its preparation method and use

A nanoparticle and grain boundary technology, applied in the field of metal-metal oxide nanoparticles, to achieve the effect of improving stability, rich source of raw materials, and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

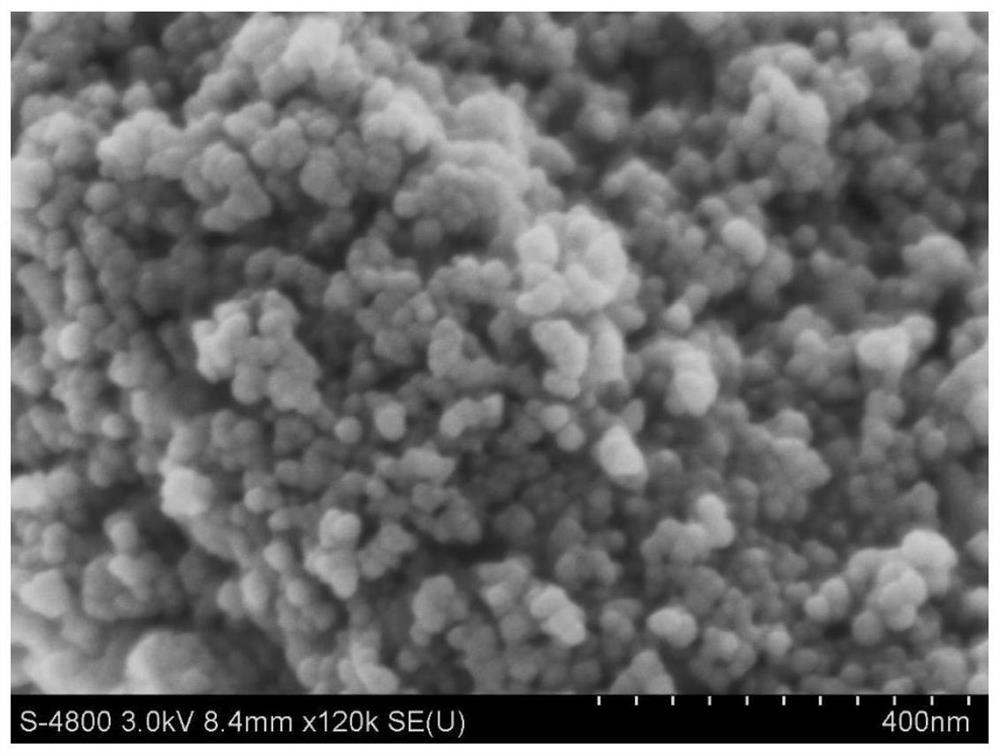

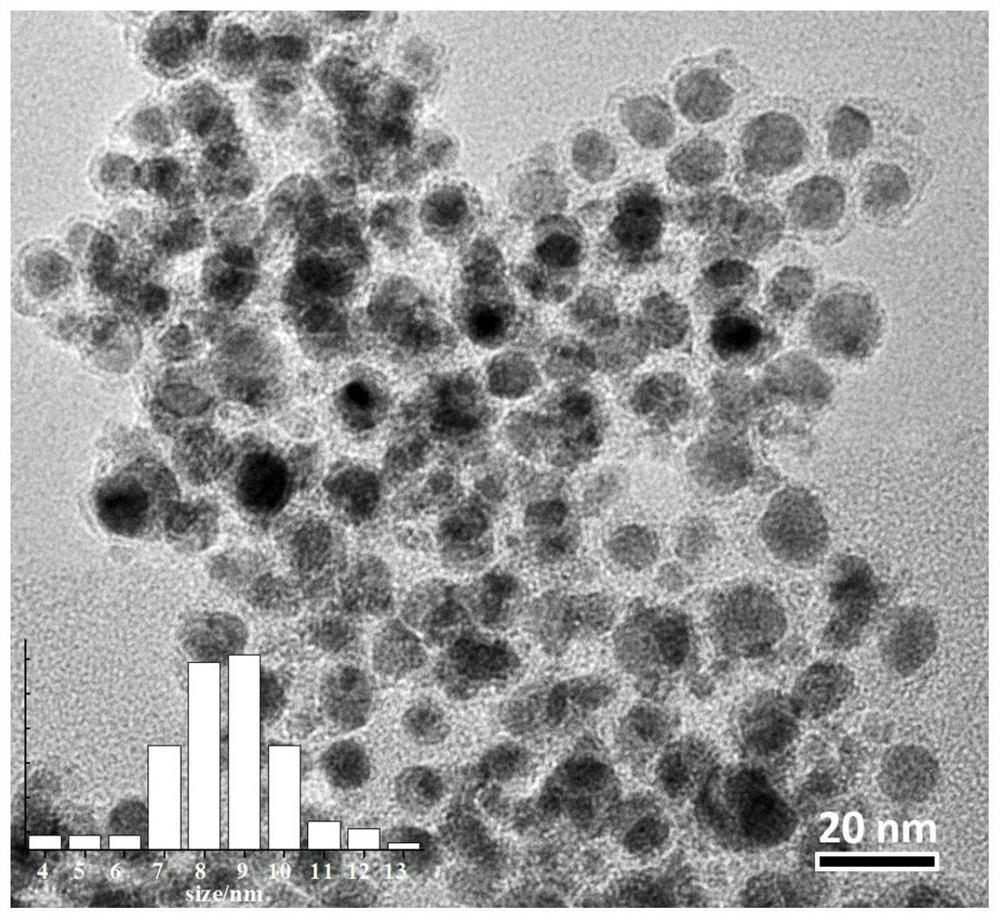

[0041] The preparation method of the nanoparticles with grain boundaries in the present invention is a solvothermal-solid phase calcination method. The precursor is first prepared by solvothermal method, and then further roasted to obtain nitrogen-doped metal-metal oxide nanoparticle powder with abundant grain boundaries. The obtained powder material has a spherical shape and a particle size of 3-20nm.

[0042] The specific steps are:

[0043] 1. Weigh an appropriate amount of metal salt (such as manganese salt, iron salt, cobalt salt, nickel salt, copper salt or zinc salt, etc.), organic nitrogen source (such as urea, melamine or amino acid, etc.) and glycerin, stir well, and the metal salt , The molar ratio of organic nitrogen source to glycerol is 1: (0.5-5): (10-100);

[0044] 2. Transfer the mixed solution obtained in step 1 to an autoclave with a polytetrafluoroethylene liner, heat and stir evenly, and react under airtight conditions at 100-180°C and autogenous pressure...

Embodiment 1

[0052] Mix 0.5g of cobalt acetate, 0.5g of nickel acetate, 1g of melamine, 5g of glycerin and 75mL of ethanol, and stir the obtained homogeneous solution into an autoclave PTFE liner; put the PTFE liner into the autoclave , sealed and placed in a constant temperature oven, and reacted in an oven at 180°C for 2h. After the reaction, cool down the autoclave, wait until the autoclave is cooled to room temperature, take out the hydrothermal precipitate, and after centrifugation and washing with ethanol, dry and grind the obtained solid to obtain a powder; place the dried powder in an inert atmosphere Calcined at 450°C for 2h, and then naturally cooled to room temperature to obtain nitrogen-doped metal-metal oxide nanoparticles with abundant grain boundaries.

[0053] Table 1 is the elemental composition of the obtained product measured by X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy energy spectroscopy (TEM-EDS) in Example 1 (both are mole percent co...

Embodiment 2

[0059] Mix 0.5g of nickel sulfate, 0.5g of ferric sulfate, 1g of urea, 20.0g of glycerin and 60mL of ethanol, and stir the obtained homogeneous solution into an autoclave PTFE liner, and put the PTFE liner into the autoclave place in a constant temperature oven after sealing, and react in an oven at 150°C for 5 hours; after the reaction, cool down the autoclave, and when the autoclave drops to room temperature, take out the hydrothermal precipitate, centrifuge and wash with ethanol, then dry and grind The powder is obtained; the dried powder is placed in an inert atmosphere furnace and calcined at 400° C. for 3 hours, and then naturally cooled to room temperature to obtain a nitrogen-doped metal-metal oxide nanoparticle product with abundant grain boundaries.

[0060] Using the product obtained in Example 2 as an anode material, the potential of electrocatalytically decomposing water to produce oxygen is 1.52V vs. RHE, which exceeds that of RuO 2 and IrO 2 The performance lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com