Highly antibacterial sealing paste for water pipe

A technology for sealing paste and water pipes, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve serious problems such as service life of water pipes, bacterial growth in connection parts, and affect the use effect, etc., to achieve inhibition Effects of microbial growth, integrity protection, and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

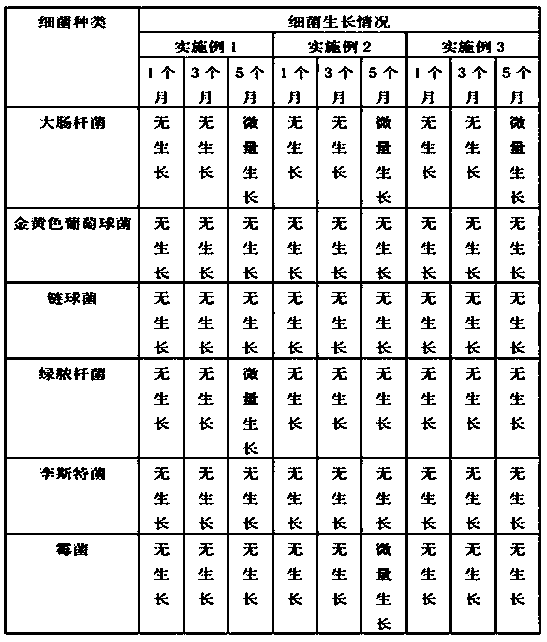

Embodiment 1

[0023] A strong antibacterial sealing paste for water pipes, said strong antibacterial sealing paste for water pipes is made of the following raw materials in parts by weight: 80 parts of neoprene glue, 10 parts of styrene-butadiene rubber, 4 parts of polytetrafluoroethylene, sea 2 parts of pumice fiber, 1.4 parts of methylparaben, 4 parts of glutaraldehyde, 2 parts of nano-silica, 1 part of diatomaceous earth, 0.6 part of basic copper carbonate, 0.6 part of dicumyl peroxide, dispersant 0.4 parts, 0.5 parts of antioxidant, 0.2 parts of thickener.

[0024] The dispersant is at least one of triethylhexyl phosphoric acid, sodium lauryl sulfate, methyl amyl alcohol and fatty acid polyethylene glycol ester; the antioxidant is diphenylamine, pentaerythritol ester and thiodipropionic acid A mixture of diesters with a mass ratio of 1:3:1; the thickener is a mixture of sodium carboxymethylcellulose and sodium bentonite with a mass ratio of 1:4.

[0025] The preparation method of the s...

Embodiment 2

[0031] A strong antibacterial sealing paste for water pipes, said strong antibacterial sealing paste for water pipes is made of the following raw materials in parts by weight: 100 parts of neoprene glue, 15 parts of styrene-butadiene rubber, 6 parts of polytetrafluoroethylene, sea 4 parts of pumice fiber, 1.6 parts of methylparaben, 6 parts of glutaraldehyde, 3 parts of nano-silica, 3 parts of diatomaceous earth, 1.2 parts of basic copper carbonate, 0.8 parts of dicumyl peroxide, dispersant 0.6 parts, 0.7 parts of antioxidant, 0.4 parts of thickener.

[0032] The dispersant is at least one of triethylhexyl phosphoric acid, sodium lauryl sulfate, methyl amyl alcohol and fatty acid polyethylene glycol ester; the antioxidant is diphenylamine, pentaerythritol ester and thiodipropionic acid A mixture of diesters with a mass ratio of 1:3:1; the thickener is a mixture of sodium carboxymethylcellulose and sodium bentonite with a mass ratio of 1:4.

[0033] The preparation method of t...

Embodiment 3

[0039] A kind of strong antibacterial sealing paste for water pipes, said strong antibacterial sealing paste for water pipes is made of the following raw materials in parts by weight: 90 parts of neoprene glue, 13 parts of styrene-butadiene rubber, 5 parts of polytetrafluoroethylene, sea 3 parts of pumice fiber, 1.5 parts of methylparaben, 5 parts of glutaraldehyde, 2.5 parts of nano silicon dioxide, 2 parts of diatomaceous earth, 1 part of basic copper carbonate, 0.7 parts of dicumyl peroxide, dispersant 0.5 parts, 0.6 parts of antioxidant, 0.3 parts of thickener.

[0040] The dispersant is at least one of triethylhexyl phosphoric acid, sodium lauryl sulfate, methyl amyl alcohol and fatty acid polyethylene glycol ester; the antioxidant is diphenylamine, pentaerythritol ester and thiodipropionic acid A mixture of diesters with a mass ratio of 1:3:1; the thickener is a mixture of sodium carboxymethylcellulose and sodium bentonite with a mass ratio of 1:4.

[0041] The preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com