Rumen protected choline chloride and preparation method thereof

A technology of choline chloride and rumen passing, applied in the field of feed additives, can solve the problems of large loss of choline chloride, complicated processing technology, expensive coating materials, etc., so as to reduce the influence of human factors, prevent and treat fatty liver, and improve the palatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

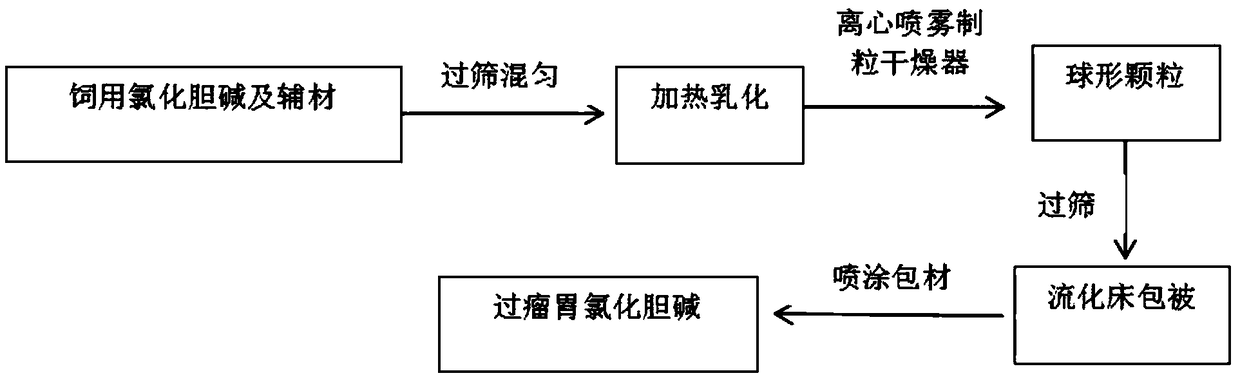

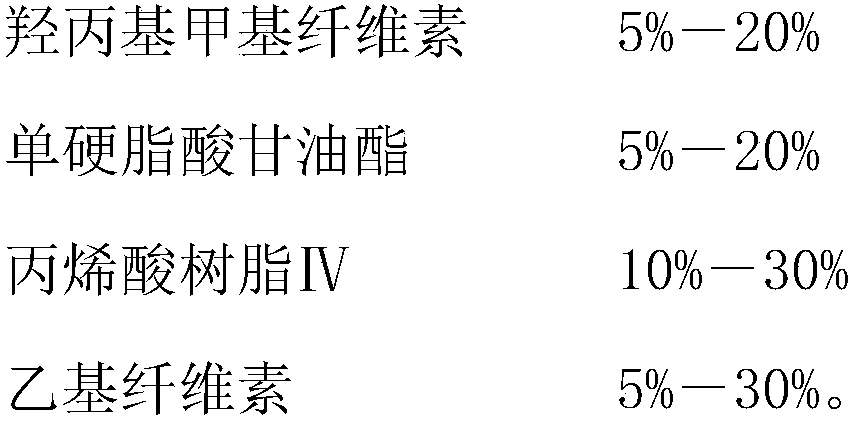

[0022] Such as figure 1 As shown, add 10kg hydroxypropyl methylcellulose, 10kg glyceryl monostearate and 40kg corncob to 5kg choline chloride, and pass through an 80-mesh sieve to mix evenly, and control the heating emulsification temperature at 80-105°C . After emulsification, it is introduced into the centrifugal spray tower, the rotation speed of the atomization disc is 4500-5500 rpm, the temperature is 180-200 ° C, the temperature is 180-200 ° C, the cooling and drying temperature is 60-70 ° C, and the prepared particles are double-layered with 30-50 mesh Sieve through a vibrating sieve and collect. Dissolve 10kg of ethyl cellulose and 20kg of acrylic resin IV into an organic solvent, spray on the bottom side of the fluidized bed granulator coating machine, and evenly spray the coating material onto the surface of the choline chloride granules, with a spray flow rate of 100-2000mL / min; fluidization air inlet temperature 50-90°C; time 2-4 hours; finally the product with ...

Embodiment 2

[0024] Such as figure 1 As shown, add 10kg of hydroxypropyl methylcellulose, 15kg of glyceryl monostearate and 25kg of corncob to 10kg of choline chloride, and pass through an 80-mesh sieve to mix evenly, and control the temperature of heating and emulsification at 80-105°C . After emulsification, it is introduced into the centrifugal spray tower, the rotation speed of the atomization disc is 4500-5500 rpm, the temperature is 180-200 ° C, the temperature is 180-200 ° C, the cooling and drying temperature is 60-70 ° C, and the prepared particles are double-layered with 30-50 mesh Sieve through a vibrating sieve and collect. Dissolve 15kg of ethyl cellulose and 20kg of acrylic resin IV into an organic solvent, spray on the bottom side of a fluidized bed granulator coating machine, and evenly spray the coating material onto the surface of the choline chloride granules, with a spray flow rate of 100-2000mL / min; fluidization air inlet temperature 50-90°C; time 2-4 hours; finally...

Embodiment 3

[0026] Such as figure 1 As shown, add 15kg hydroxypropyl methylcellulose, 15kg glycerol monostearate and 10kg corncob to 20kg choline chloride, and pass through an 80-mesh sieve to mix evenly, and control the heating emulsification temperature at 80-105°C . After emulsification, it is introduced into the centrifugal spray tower, the rotation speed of the atomization disc is 4500-5500 rpm, the temperature is 180-200 ° C, the temperature is 180-200 ° C, the cooling and drying temperature is 60-70 ° C, and the prepared particles are double-layered with 30-50 mesh Sieve through a vibrating sieve and collect. Dissolve 15kg of ethyl cellulose and 20kg of acrylic resin IV into an organic solvent, spray on the bottom side of a fluidized bed granulator coating machine, and evenly spray the coating material onto the surface of the choline chloride granules, with a spray flow rate of 100-2000mL / min; fluidization air inlet temperature 50-90°C; time 2-4 hours; finally the product with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com