A kind of water-soluble polyester imide insulating paint and preparation method thereof

A technology of polyester imide and insulating varnish, applied in the direction of coating, etc., can solve the problems of poor mechanical strength and poor heat resistance of water-based insulating varnish, achieve high sealing efficiency, improve mechanical strength, and improve hydrolysis resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

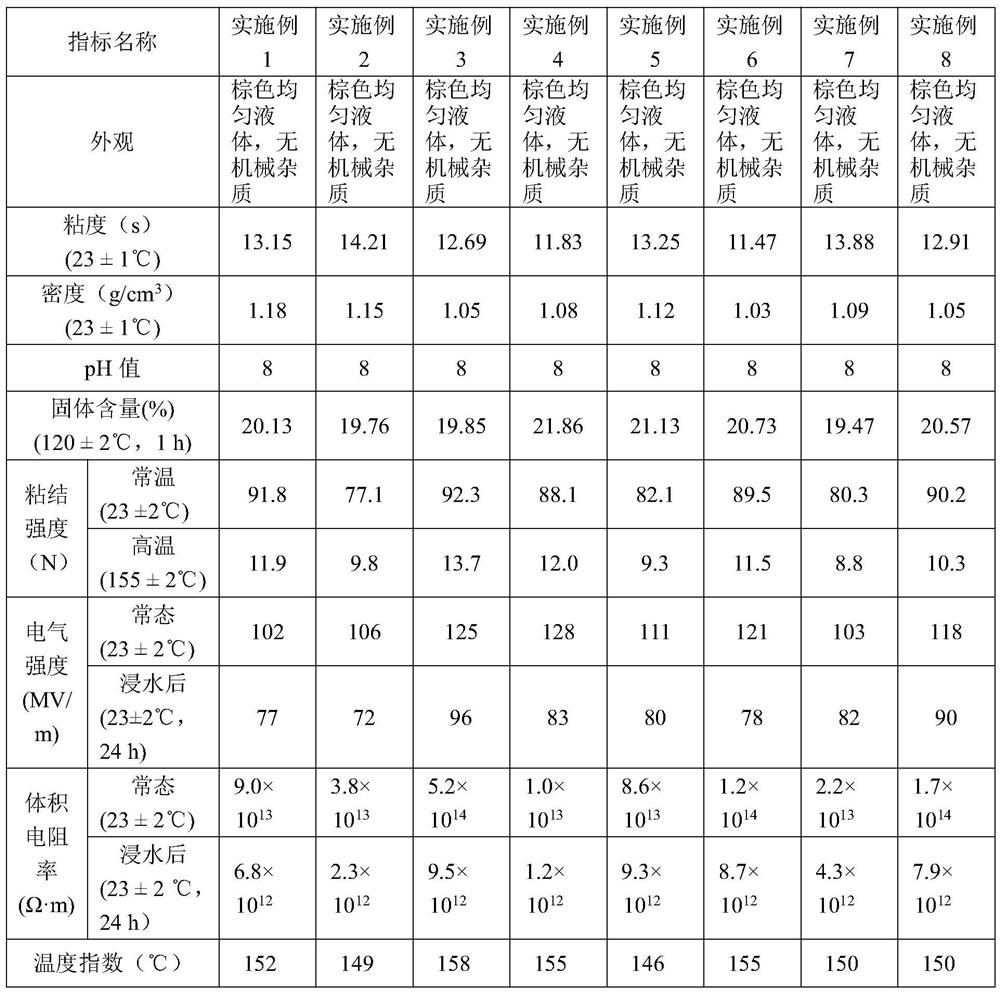

Examples

preparation example Construction

[0029] Present embodiment also provides a kind of preparation method of water-soluble polyester imide insulating varnish, comprises the steps:

[0030] (1) prepare materials by parts by weight of each raw material;

[0031] (2) Add ordinary diols, polyols, diamines and polybasic anhydrides into a reaction flask equipped with a stirring device, a temperature control device and a reflux condensation device, heat the mixture to 140-160°C, and wait for the mixture to melt Then start stirring, continue to heat up the molten mixture to 160-190°C, and start to cool down after imide reaction for 3-5 hours; when the temperature of the mixture drops to 80-100°C, add dibasic acid and / or Or dibasic acid anhydride, hydrophilic functional diol, slowly raise the temperature of the mixed liquid to 160-190°C, after 2-4 hours of esterification, then raise the temperature of the mixed liquid to 190-220°C, polycondensation reaction 4 ~6h, when the acid value reaches 40~70mgKOH / g, start to cool d...

Embodiment 1

[0040] Embodiment 1 of the present invention provides a kind of water-soluble polyester imide insulating varnish, and it comprises the raw material of following weight: neopentyl glycol 73.7g, trimethylol propane 26.8g, diaminodiphenyl ether 8g, partial 15.4g of benzenetricarboxylic anhydride, 65.2g of isophthalic acid, 29.2g of adipic acid, 51.5g of phthalic anhydride, 23.1g of 2,2-dimethylolpropionic acid, 22.5g of glycidyl tert-carbonate, ethylene glycol monobutyl ether 118 g, N,N-dimethylethanolamine 24 g, Cymel 325 amino resin 100 g and water 1200 g.

[0041] Present embodiment also provides the preparation method of this water-soluble polyester imide insulating varnish, comprises the steps:

[0042] 73.7g neopentyl glycol, 26.8g trimethylolpropane, 8g diaminodiphenyl ether, 15.4g trimellitic anhydride are added in the reaction bottle that stirring device, temperature control device and reflux condensation device are housed, react Slowly heat the bottle to 140°C, start s...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a kind of water-soluble polyester imide insulating varnish, and it comprises the raw material of following weight: 1,4 cyclohexanedimethanol 76.1g, trimethylolpropane 53.6g, diaminodiphenyl 4g of methane, 7.68g of trimellitic anhydride, 23.6g of succinic acid, 45.2g of isophthalic acid, 77.4g of phthalic acid, 23.1g of 2,2-dimethylolpropionic acid, 20g of glycidyl tertiary carbonate , ethylene glycol monobutyl ether 122g, N,N-dimethylethanolamine 22g, INEOS Resimene 717 amino resin 100g and water 1200g.

[0045] Present embodiment also provides the preparation method of this water-soluble polyester imide insulating varnish, comprises the steps:

[0046] Add 76.1g of 1,4-cyclohexanedimethanol, 53.6g of trimethylolpropane, 4g of diaminodiphenylmethane, and 7.68g of trimellitic anhydride into a reaction flask equipped with a stirring device, a temperature control device and a reflux condensing device In the process, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com