Method for producing pentanediamine through fermentation and method for extracting pentanediamine

A technology of pentamethylenediamine and extractant, which is applied in the field of bio-fermentation engineering, can solve the problems such as the decrease of catalytic efficiency of lysine sulfate, and achieve the effect of high added value and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 Material testing methods and instruments

[0065] The following methods and instruments are used to detect the content and purity of 1,5-pentanediamine and the performance indicators of nylon 56.

[0066] (1) Analysis of 1,5-pentanediamine content (unit: g / L)

[0067] Chromatographic column: American Eclipse XDB-C18column (4.6×150nm; Agilent Technologies, USA) column.

[0068] Detector: secondary array detector DAD (detection wavelength 360nm, reference wavelength 400nm).

[0069] Mobile phase: A: pH 7.2 potassium dihydrogen phosphate aqueous solution; B: 66% acetonitrile aqueous solution

[0070] Gradient ratio A: B=5%: 95%

[0071] Flow rate: 1.0ml / min

[0072] Column temperature: 40℃

[0073] Injection volume: 15.0μL

[0074] Detection method: using 2,4-dinitrofluorobenzene (DNFB) HPLC pre-column derivatization method.

[0075] (2) Purity analysis of 1,5-pentanediamine (unit: wt%)

[0076] Instrument: Shimadzu GC-2010 gas chromatograph

[0077] Chromatographic column: Quartz...

Embodiment 2

[0094] Example 2 Construction of engineering bacteria

[0095] With reference to the detailed description of Chinese Patent Application No. 201610322421.5, an engineered bacteria producing 1,5-pentanediamine was constructed and named E. coli BL21 (DE3) P cadB :: P T7 / pet28a- cadA * , Wherein the amino acid sequence of lysine decarboxylase is shown in SEQ ID NO: 2, and the nucleotide sequence of the coding gene is shown in SEQ ID NO: 1.

[0096] In addition, based on our preliminary screening of alanine, we found a lysine decarboxylase that is more suitable for catalyzing lysine sulfate. Its amino acid sequence is shown in SEQ ID NO: 4, with an A at position 315. For amino acid mutation, the nucleotide sequence of the coding gene is shown in SEQ ID NO:3. Basically referring to the above method, the only difference is that the mutant gene was substituted to construct an engineered bacteria producing 1,5-pentanediamine, named E. coli BL21 (DE3) P cadB :: P T7 / pet28a- cadA *3...

Embodiment 3

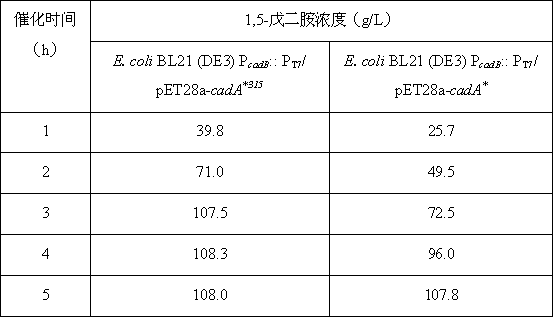

[0097] Example 3 Catalytic production based on lysine sulfate

[0098] Take the two engineering bacteria constructed in Example 2 respectively, refer to the detailed description of Chinese Patent Application No. 201610322421.5, and obtain OD by seed solution culture, fed-feed culture and IPTG induction culture. 600 The cell culture solution that reached about 80 was centrifuged to obtain the respective wet cells.

[0099] Prepare a catalytic liquid system containing 208 g / L lysine sulfate and 0.2 mmol / L pyridoxal phosphate (PLP), adjust the temperature to 37°C, set the fermenter stirring speed to 500 rpm, and add 20 g / L respectively The above-mentioned two kinds of wet bacteria (equivalent to the dry cell weight 4 g / L) start whole-cell catalysis. No acidic substances are added to adjust pH, and no air is passed through, using by-product CO 2 Adjust the pH of the self-regulating catalytic system. Take out the catalytic liquid from the fermenter every 1h, 12000 × g Centrifuge for 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com