Multilevel-structure ZSM-5 zeolite-molecular sieve catalyst, preparation method therefor and application of multilevel-structure ZSM-5 zeolite-molecular sieve catalyst

A ZSM-5, zeolite molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve problems such as difficult process control, decreased hydrothermal stability, and destruction of zeolite, and achieve optimized catalysis The performance, the preparation process is simple, and the repeatability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] As a detailed example of a high-performance methanol-to-propylene catalyst preparation method, the main preparation steps are as follows: first, uniformly mix the silicon source, the aluminum source, and deionized water, wherein the molar ratio of the silicon source to the aluminum source is 100 to 400: 1; Secondly, slowly add the microporous structure-directing agent solution to the above mixed solution dropwise, wherein the molar ratio of the microporous structure-directing agent to the silicon source is 0.07-0.16:1, and the dropping process is controlled within 5-20 minutes Continue to stir for 2 to 5 hours until the silicon source and aluminum source are completely hydrolyzed, and the precursor mixed solution is clear; then, dry the precursor solution in a water bath at 30 to 60°C to obtain a xerogel; next, grind the xerogel Fine, crystallized under steam-assisted conditions at 100-180°C for 5-48 hours; the crystallized mixture was fully dried and calcined at 400-600...

Embodiment 1

[0051] a) Stir 10.42 grams of tetraethyl orthosilicate, 0.0511 grams of aluminum isopropoxide and 18 grams of deionized water in a water bath at 25°C for 0.5 hours (at a rate of 400 rpm), until they are evenly mixed;

[0052] b) 4.0672 grams of tetrapropylammonium hydroxide (25wt% aqueous solution) was slowly dripped into the above mixed solution, the process of dropping was controlled in 10 minutes, and the stirring was continued in a water bath at 25°C (speed was 400 rpm) for 3 hours Until the silicon source and the aluminum source are fully hydrolyzed, the mixed solution is clarified;

[0053] c) Increase the temperature of the water bath to 40° C. and continue to stir (at a rate of 400 rpm) the precursor solution to obtain a gel, and continue to dry the resulting gel until its mass reaches 5.7 grams;

[0054] d) Use an agate mortar to grind the above-mentioned xerogel into powder and then transfer it to a crucible, put the crucible containing the xerogel powder into 80 ml ...

Embodiment 2

[0067] The difference between this example and Example 1 is that the molar ratio of the microporous structure-directing agent to the silicon source is 0.13. All the other contents are the same as those described in Example 1.

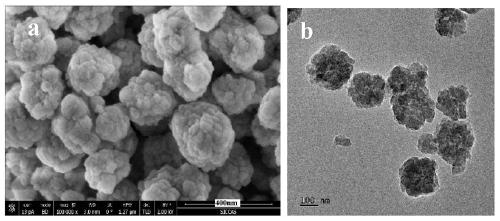

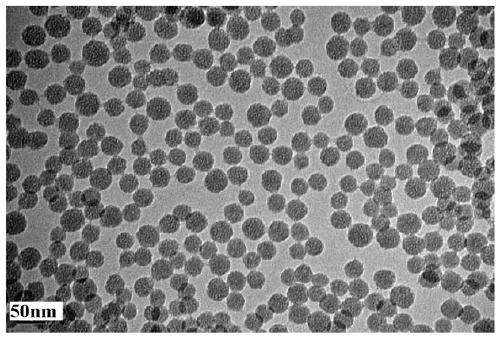

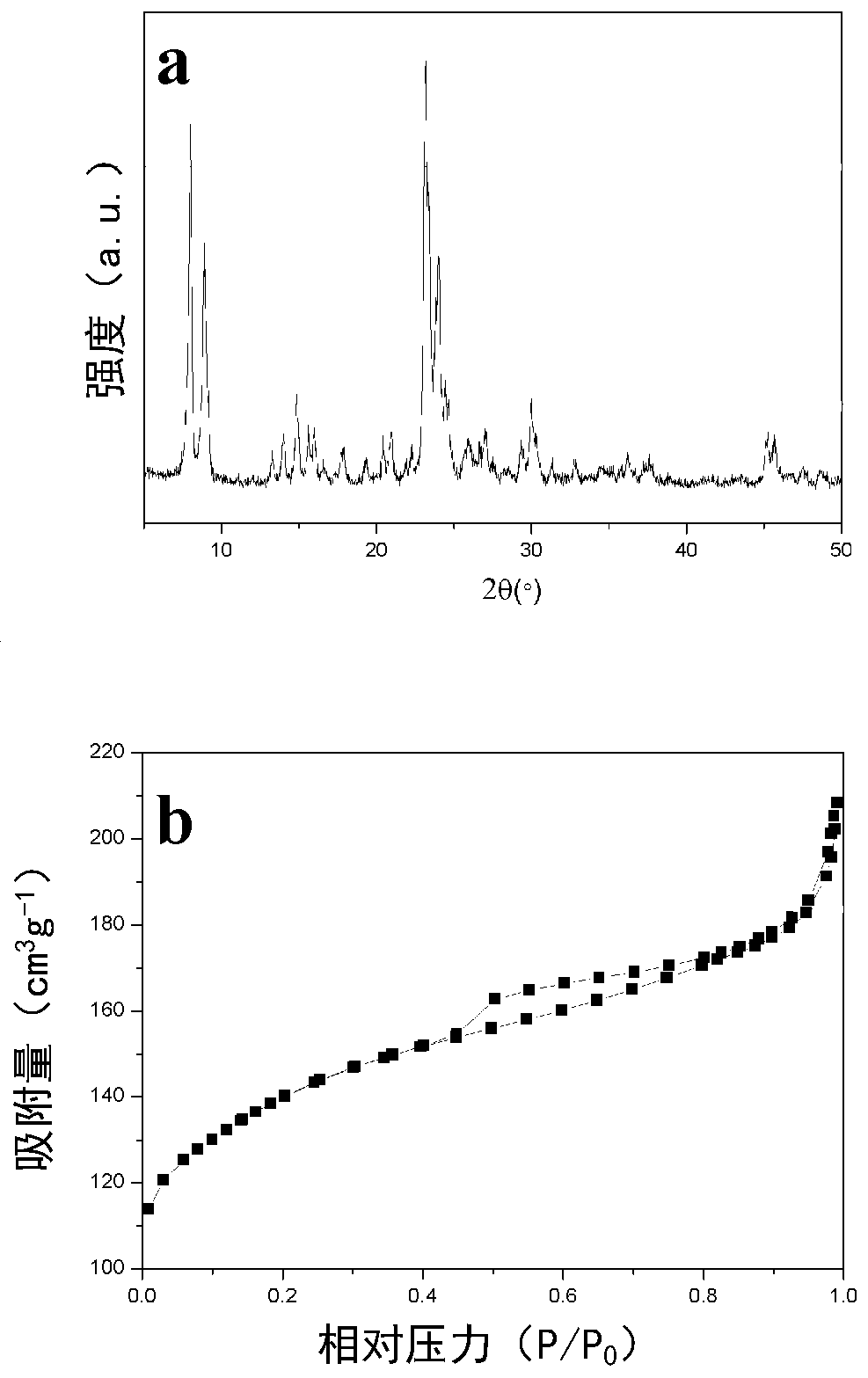

[0068] Figure 4 The SEM of the hierarchical structure ZSM-5 zeolite molecular sieve catalyst that is embodiment 2 Figure 4 Middle a) and TEM photo ( Figure 4 Middle b). Depend on Figure 4 It can be seen that zeolite presents spherical particles with a diameter of 200-250 nanometers and the surface is loose and porous, and there are mesoporous channels inside the zeolite particles (pore diameter 4-7nm);

[0069] Table 3 is the quantitative result of pyridine adsorption FTIR spectrum after desorption at 200°C:

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com