Bioactive ceramic fiber composite scaffold for bone repair and preparation method of composite scaffold

A bioactive ceramic and fiber composite technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as difficult processing, high brittleness, unsatisfactory degradability and biological activity, etc., to improve brittleness, high brittleness, Effect of Cytocompatibility Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

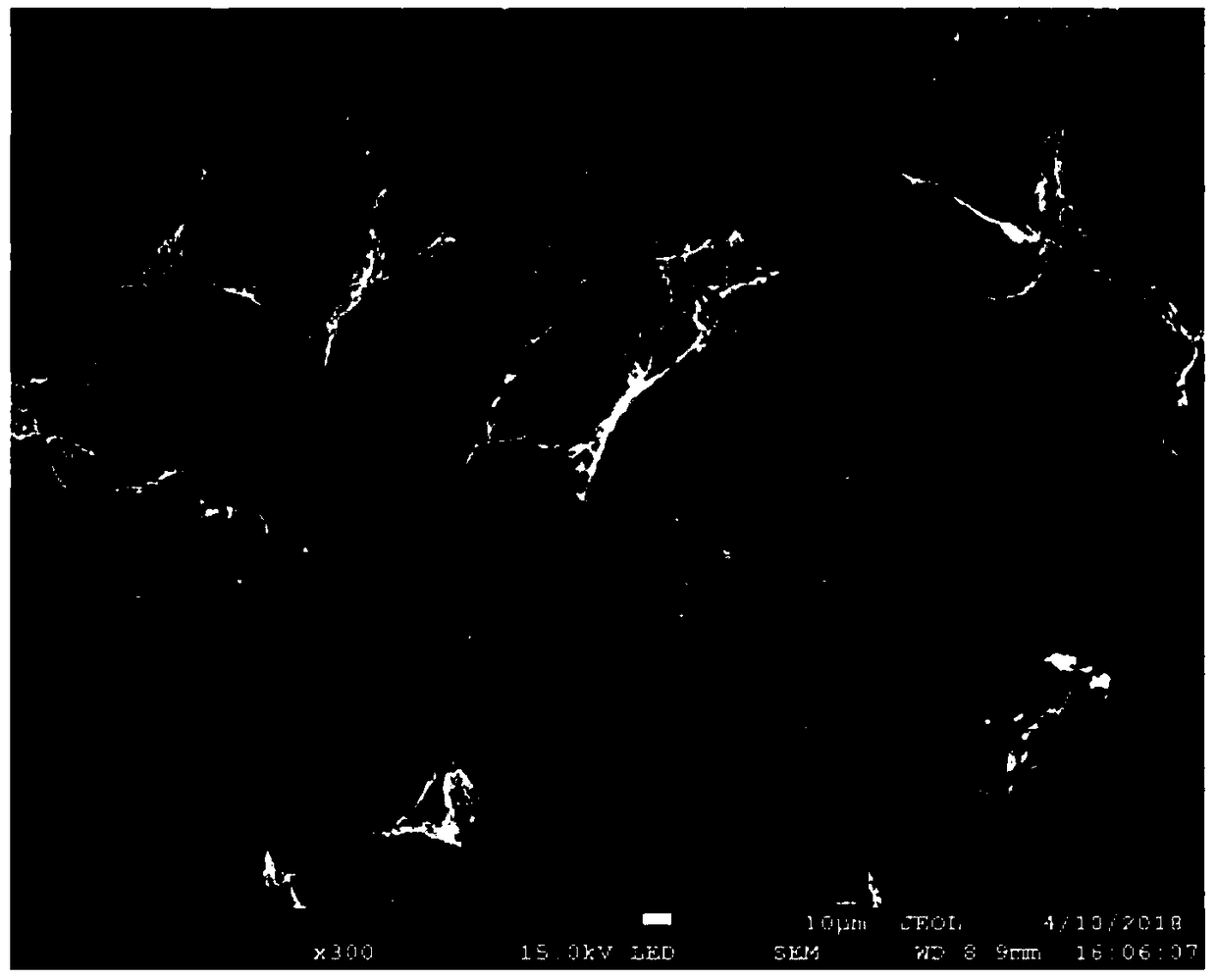

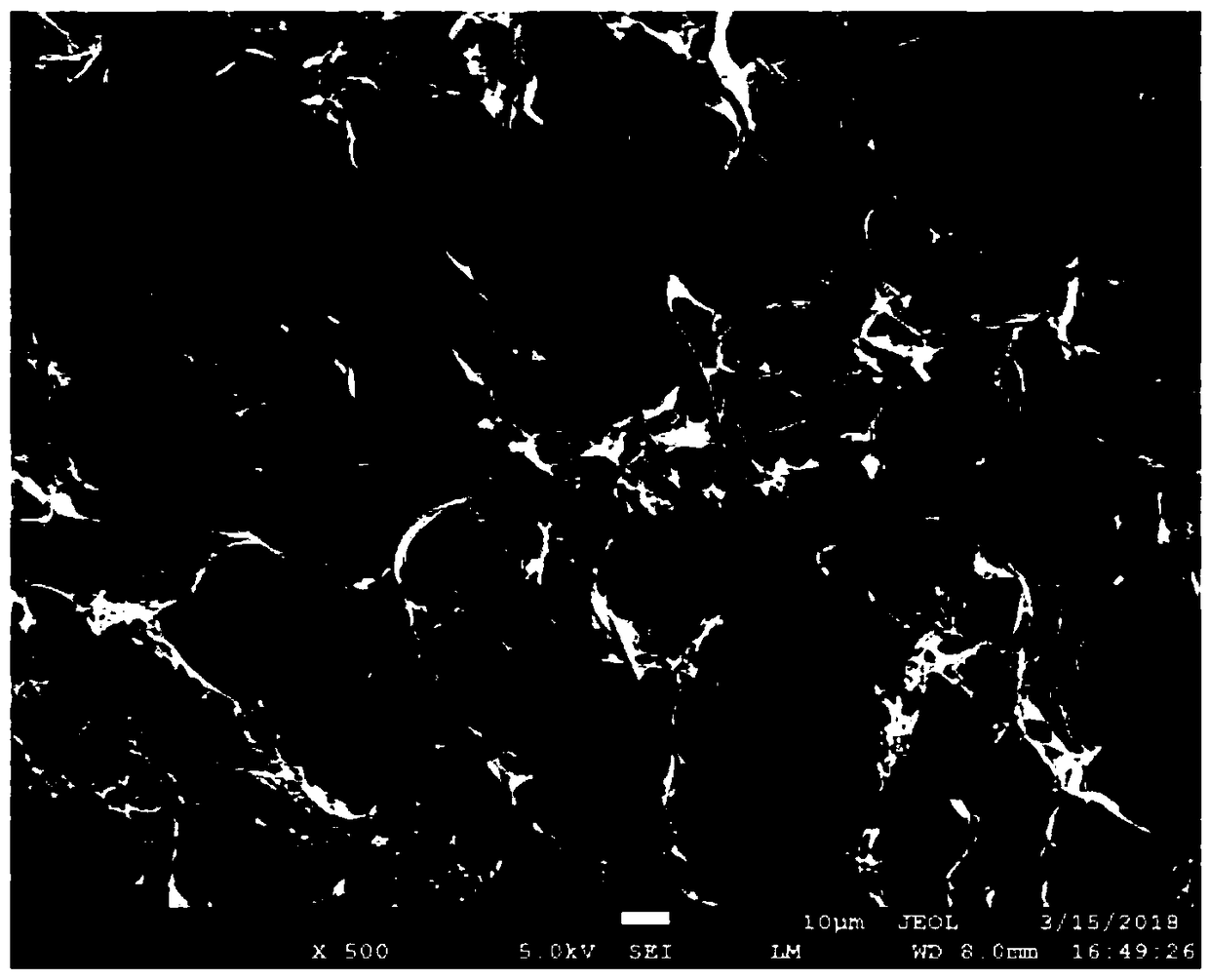

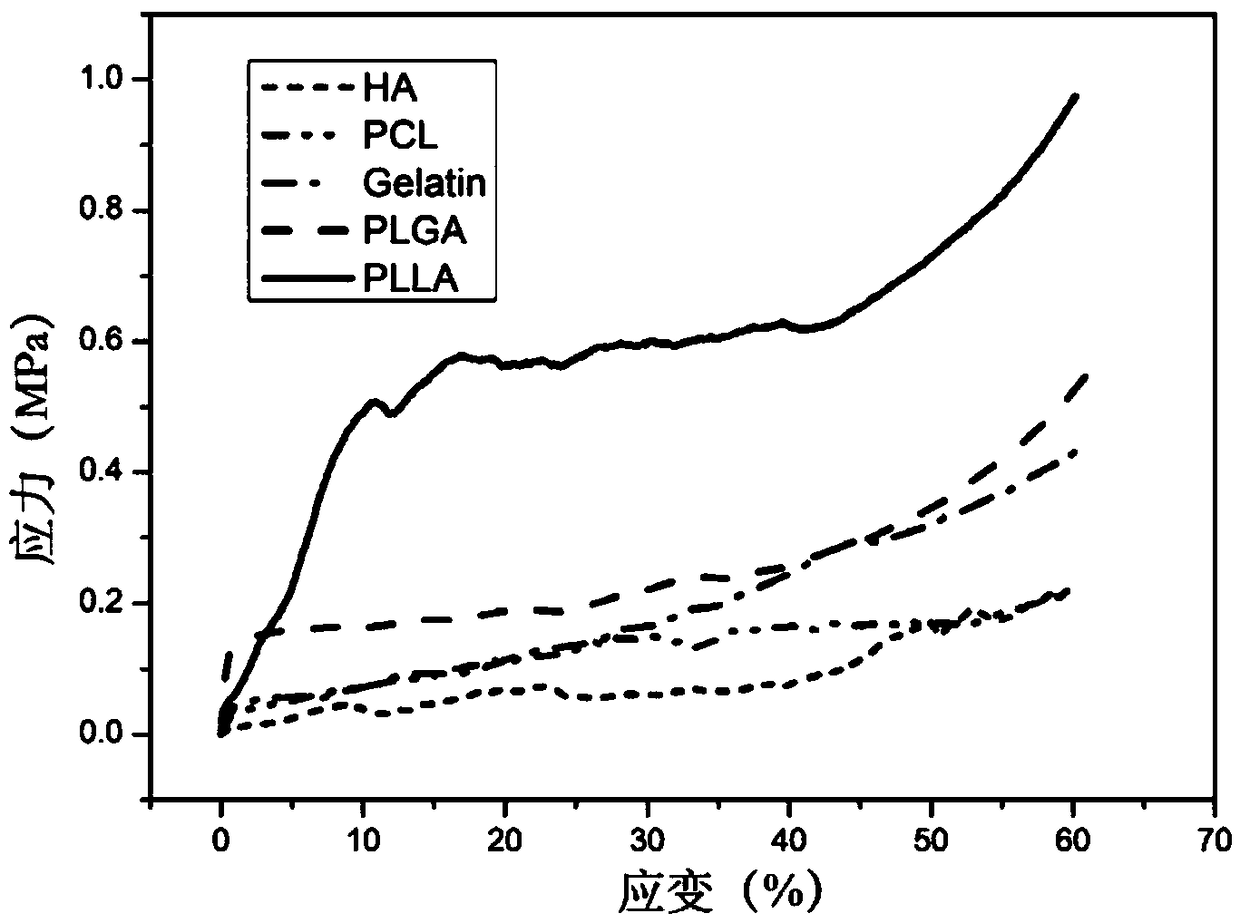

Image

Examples

Embodiment 1

[0033] (1) Add 7.56g of calcium nitrate tetrahydrate to 15ml of ethanol and ultrasonically dissolve it for 2h, add 800μl of 1mol / L dilute hydrochloric acid solution and 15.14ml of tetraethyl orthosilicate, stir and age in a water bath at 37°C for 3 days to obtain a sol-gel solution.

[0034] (2) Dissolve 1 g of polyvinyl alcohol in 9 g of ethanol to prepare a clear and transparent solution with a concentration of 10 wt.%, mix it with the sol-gel solution prepared in step (1), and stir overnight in a 37° C. water bath with magnetic force.

[0035] (3) Spinning the precursor solution obtained in step (2) by electrospinning process to obtain a fiber membrane, the spinning parameters are: voltage 22kV, receiving distance 15cm, flow rate 0.6ml / h, and the humidity of the environment is controlled at 20±5o, the temperature is 35±2℃.

[0036] (4) Cut 0.2g of the fiber membrane obtained in step (3) into 1*1cm 2 Fragments of different sizes are suspended in 20ml of deionized water, an...

Embodiment 2

[0042] (1) Mix 10ml of triethyl phosphate with deionized water and absolute ethanol at a molar ratio of 1:3:3, hydrolyze at 80°C for 28 hours, and cool to room temperature as a phosphorus source.

[0043] (2) Weigh 7.56g of calcium nitrate tetrahydrate and add it into 15ml of ethanol, and ultrasonically dissolve it for 2 hours as a calcium source.

[0044] (3) Add 15.14ml tetraethyl orthosilicate to the calcium source in step (2), and stir in a water bath at 37°C for 12h until clear and transparent.

[0045] (4) Add the solution in step (3) dropwise to the phosphorus source solution prepared in step (1), and control the molar ratio of feeding calcium to phosphorus to be 1.3. After the dropwise addition was completed, the stirring was continued for 3 h, and then the sol was placed in a water bath at 37° C., and stirred by magnetic force for 3 days for sufficient aging.

[0046] (5) Mix the fully aged gel with water and 5wt.% spinning aid polyvinylpyrrolidone aqueous solution a...

Embodiment 3

[0053] (1) Mix 10ml of triethyl phosphate with deionized water and absolute ethanol at a molar ratio of 1:3:3, hydrolyze at 80°C for 28 hours, and cool to room temperature as a phosphorus source.

[0054] (2) Weigh 6.80g of calcium nitrate tetrahydrate and 0.82g of magnesium nitrate hexahydrate into 15ml of ethanol, and ultrasonically dissolve it for 2 hours.

[0055] (3) Add the solution in step (2) dropwise to the phosphorus source solution prepared in step (1), and control the ratio of calcium to phosphorus to be 1.3. After the dropwise addition was completed, the stirring was continued for 3 h, and then the sol was placed in a water bath at 37° C. and stirred by magnetic force for 3 days to fully age.

[0056] (4) Mix the fully aged gel with 5wt.% spinning aid, that is, polyvinyl butyral solution at a mass ratio of 5:1, and stir magnetically for 24 hours in a water bath at 37°C to obtain a transparent Clear spinning solution. Electrospinning equipment is used for spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com